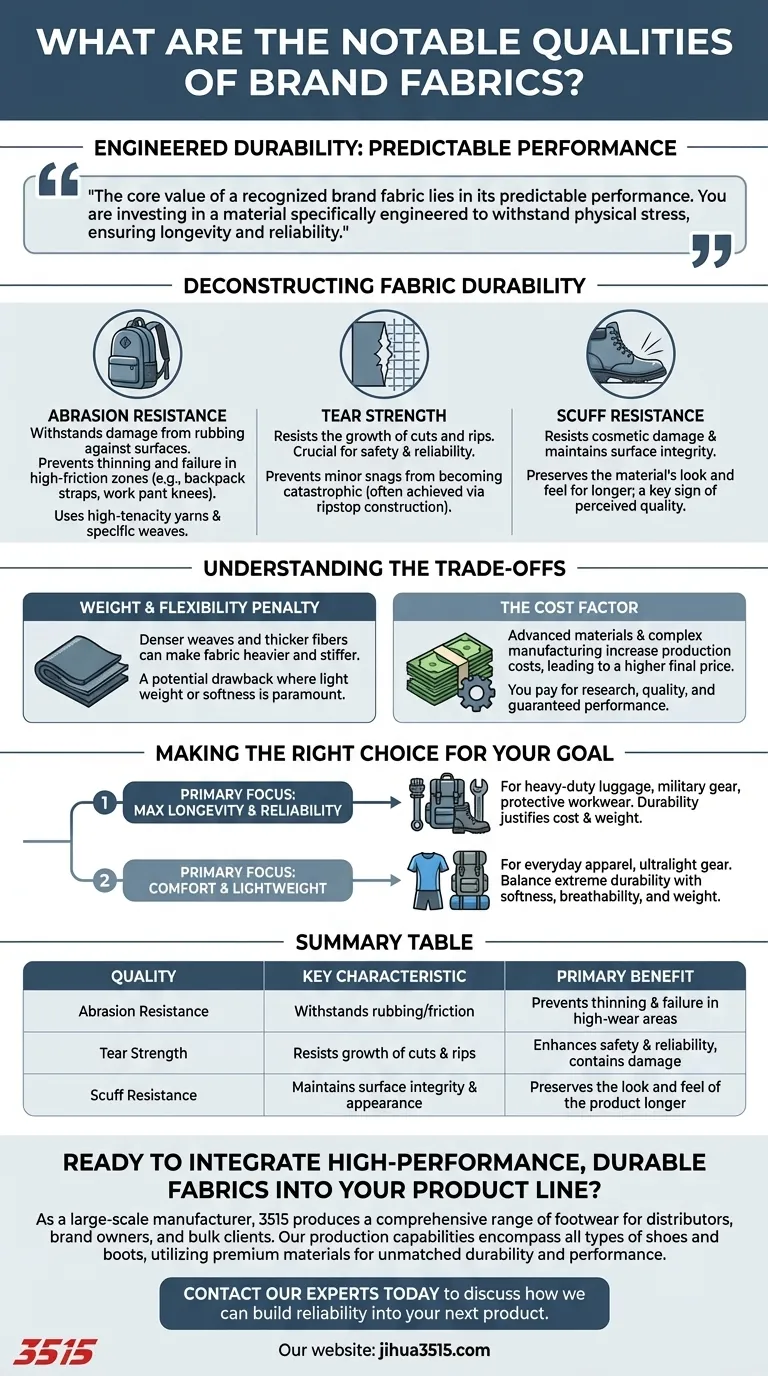

The defining quality of brand fabrics is their engineered durability. This is not simply about lasting a long time, but about a measurable and consistent resistance to the specific forces that degrade textiles: abrasions, tears, and scuffs.

The core value of a recognized brand fabric lies in its predictable performance. You are investing in a material specifically engineered to withstand physical stress, ensuring longevity and reliability in demanding applications.

Deconstructing Fabric Durability

The term "durability" can be vague. In high-performance textiles, it refers to several distinct, measurable characteristics that work together to extend the life of a product.

The Impact of Abrasion Resistance

Abrasion resistance is a fabric's ability to withstand damage from rubbing against another surface. This is one of the most common causes of wear in gear and apparel.

Think of the shoulder straps of a backpack or the knees of a pair of work pants. Consistent friction wears down fibers, leading to thinning and eventual failure. Brand fabrics are often constructed with high-tenacity yarns and specific weaves to minimize this damage.

Understanding Tear Strength

Tear strength measures a fabric's ability to resist the growth of a cut or rip. Once a tear starts, a fabric with low tear strength will unravel or separate easily.

This quality is crucial for safety and reliability. A fabric with high tear strength, often achieved through ripstop construction, can contain damage to a small area, preventing a minor snag from becoming a catastrophic failure.

The Role of Scuff Resistance

While related to abrasion, scuff resistance often refers to a fabric's ability to resist cosmetic damage. It's about maintaining the material's surface integrity and appearance.

Scuffs may not compromise the structural integrity immediately, but they are the first sign of wear. Fabrics designed to resist scuffing maintain their look and feel for longer, which is a key component of perceived quality.

Understanding the Trade-offs

Choosing a highly durable fabric involves accepting certain compromises. No single material is perfect for every application, and understanding these trade-offs is key to making an informed decision.

The Weight and Flexibility Penalty

Exceptional durability often comes from using denser weaves and thicker, stronger fibers. This can make the resulting fabric heavier and stiffer than less durable alternatives. For applications where light weight or a soft feel is paramount, this can be a significant drawback.

The Cost Factor

The advanced materials and complex manufacturing processes required to produce high-performance, durable fabrics invariably lead to a higher cost. This expense is passed on to the consumer, making the final product more expensive. You are paying for the research, development, and quality control that guarantee performance.

Making the Right Choice for Your Goal

Your final decision should be guided by the intended use of the product.

- If your primary focus is maximum longevity and reliability: For items like heavy-duty luggage, military gear, or protective workwear, the durability of a brand fabric justifies the trade-offs in cost and weight.

- If your primary focus is comfort or lightweight performance: For everyday apparel or ultralight backpacking gear, you may need to balance extreme durability with factors like softness, breathability, and weight.

Ultimately, choosing a product with a specialized brand fabric is an investment in predictable performance for a specific purpose.

Summary Table:

| Quality | Key Characteristic | Primary Benefit |

|---|---|---|

| Abrasion Resistance | Withstands damage from rubbing/friction | Prevents thinning and failure in high-wear areas |

| Tear Strength | Resists growth of cuts and rips | Enhances safety and reliability, contains damage |

| Scuff Resistance | Maintains surface integrity and appearance | Preserves the look and feel of the product longer |

Ready to integrate high-performance, durable fabrics into your product line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, utilizing premium materials for unmatched durability and performance.

Contact our experts today to discuss how we can build reliability into your next product.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability