At its core, a safety-toe boot's primary job is to protect your feet from impact and compression. The main types are distinguished by the material used in the protective toe cap: steel toe, composite toe, and alloy toe. Each offers certified protection but brings a different set of properties regarding weight, conductivity, and cost.

The decision between steel, composite, or alloy toe protection is not about which is "best" overall, but about which material's specific trade-offs best match the unique hazards and demands of your work environment.

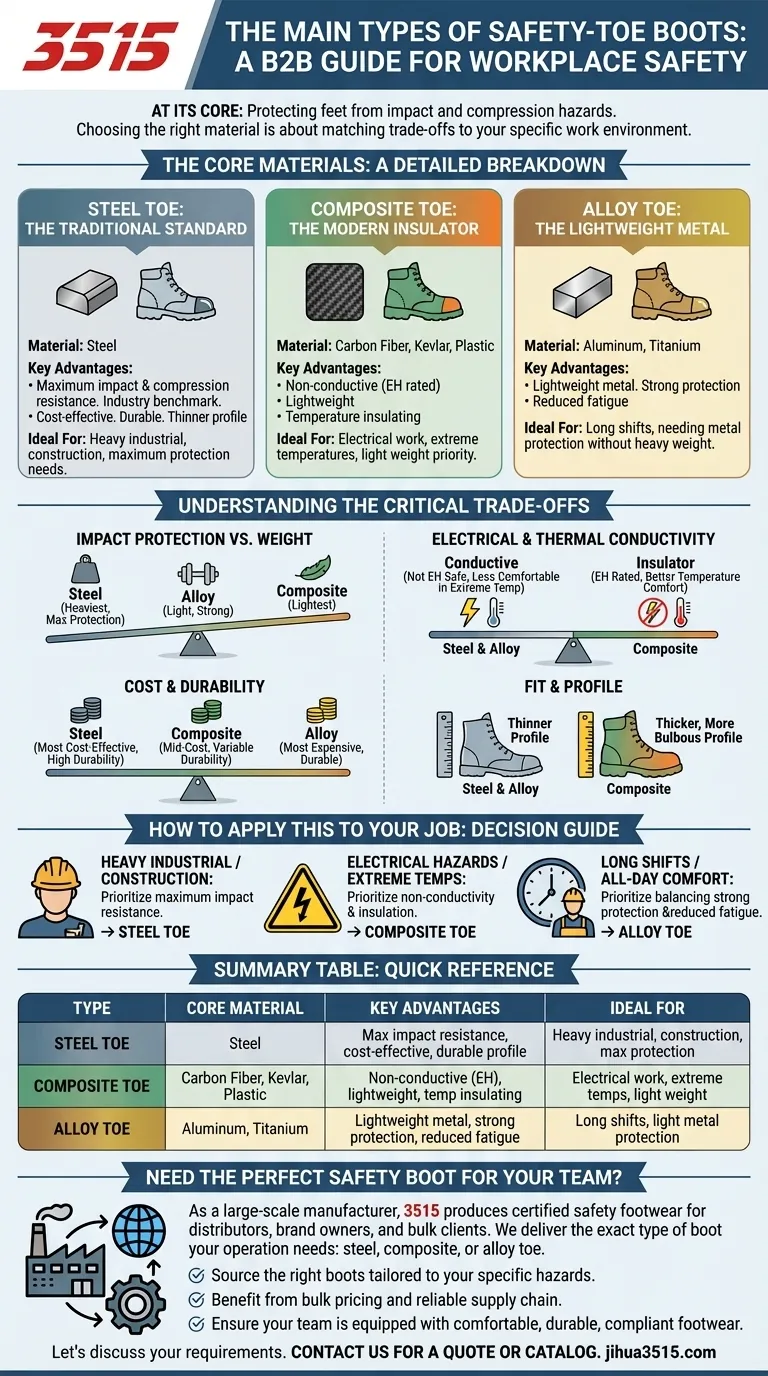

The Core Materials: A Detailed Breakdown

Choosing the right safety boot begins with understanding the fundamental differences between the materials used for the protective toe cap. Each has been engineered to solve a specific set of problems on the job site.

Steel Toe: The Traditional Standard

Steel was the original material for safety toes and remains the industry benchmark for heavy-duty protection. It provides the maximum possible defense against impact and compression hazards.

Because of its strength, a steel toe cap can be made relatively thin, resulting in a less bulky boot profile compared to some composite alternatives.

Composite Toe: The Modern Insulator

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is that they do not conduct electricity, making them the only safe choice for electricians or those working near live circuits.

They are also significantly lighter than steel and do not conduct heat or cold, providing better comfort in extreme temperature environments.

Alloy Toe: The Lightweight Metal

Alloy toes are crafted from lightweight metals such as aluminum or titanium. They provide the same high level of impact and compression resistance as steel but in a significantly lighter package.

This makes them an excellent middle-ground option, offering robust metal protection without the fatigue-inducing weight of traditional steel toes.

Understanding the Critical Trade-offs

No single material is superior in every category. Your choice requires a clear understanding of the compromises you are making in exchange for specific benefits.

Impact Protection vs. Weight

Steel offers the highest level of protection but is also the heaviest, which can lead to fatigue over a long shift. Alloy provides comparable protection at a reduced weight, while composite is the lightest option of all.

Electrical and Thermal Conductivity

This is a non-negotiable safety factor. Composite is a complete insulator, making it essential for electrical hazard (EH) rated boots. Steel and alloy, being metals, are highly conductive of both electricity and temperature, making them unsuitable for such work and less comfortable in extreme weather.

Cost and Durability

Steel toe boots are often the most cost-effective and are exceptionally durable. Alloy toe boots tend to be the most expensive due to the higher cost of the materials. Composite materials fall in the middle, though their cost can vary based on the specific blend of materials used.

Fit and Profile

To achieve the same safety rating as steel, a composite toe cap must often be thicker and more bulbous. This can affect the overall fit and comfort of the boot, so trying them on is crucial. Steel and alloy can achieve their strength in a thinner profile.

How to Apply This to Your Job

Your daily work environment is the ultimate guide to selecting the right boot. Prioritize the feature that addresses your greatest risk.

- If your primary focus is maximum impact resistance in heavy industrial or construction settings: A steel toe provides the most reliable and cost-effective protection.

- If your primary focus is safety around electrical hazards or comfort in extreme temperatures: A composite toe is the only appropriate choice.

- If your primary focus is balancing strong protection with all-day comfort and reduced fatigue: An alloy toe offers a premium, lightweight alternative to steel.

Ultimately, the right safety boot empowers you to perform your job safely and effectively by neutralizing the specific risks you face.

Summary Table:

| Type | Core Material | Key Advantages | Ideal For |

|---|---|---|---|

| Steel Toe | Steel | Maximum impact resistance, cost-effective, durable profile | Heavy industrial, construction, maximum protection needs |

| Composite Toe | Carbon Fiber, Kevlar, Plastic | Non-conductive (EH rated), lightweight, temperature insulating | Electrical work, extreme temperatures, light weight priority |

| Alloy Toe | Aluminum, Titanium | Lightweight metal, strong protection, reduced fatigue | Long shifts, needing metal protection without heavy weight |

Need the Perfect Safety Boot for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We have the production capabilities to deliver the exact type of boot your operation needs—whether it's steel, composite, or alloy toe.

We help you:

- Source the right boots tailored to your specific workplace hazards.

- Benefit from bulk pricing and reliable supply chain efficiency.

- Ensure your team is equipped with comfortable, durable, and compliant footwear.

Let's discuss your requirements. Contact our team today to get a quote or request a catalog!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How does the ergonomic design of protective footwear reduce the risk of WMSD? Enhance Worker Safety and Comfort

- What role does professional protective footwear play in preventing musculoskeletal injuries? Stay Safe & Stable

- How does repeated exposure to high temperatures damage safety boots? Avoid Costly Structural Failures

- What are the technical advantages of integrating sensors into safety shoes? Achieve Superior Motion Capture Precision

- What is the role of social media platforms as integration tools in the marketing of industrial and safety footwear?

- Is safety toe better than steel toe? A Guide to Choosing the Right Protection

- What are the benefits of providing appropriate footwear for employees? Boost Safety, Productivity & Morale

- What are the technical advantages of integrating flexible sensing technology and FSR into footwear? Boost Smart Safety