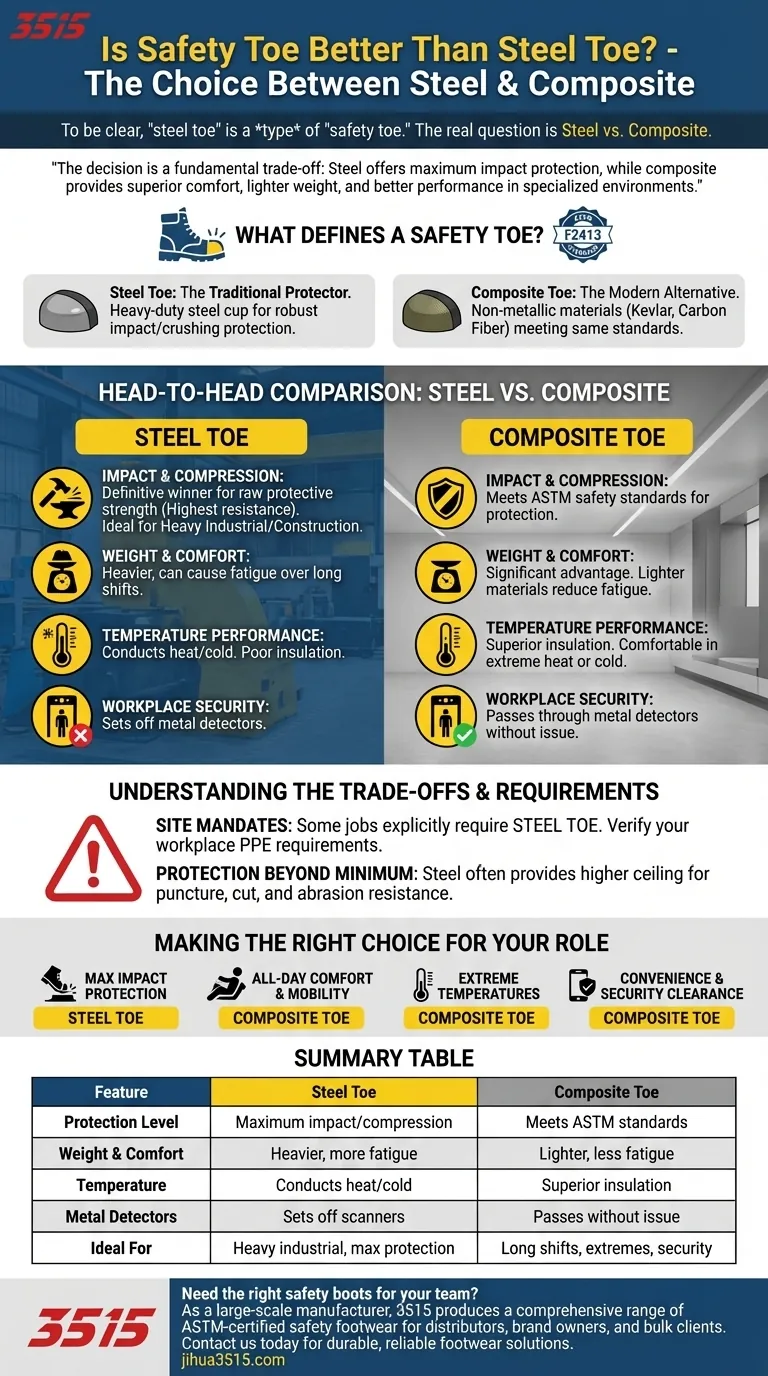

To be clear, a "steel toe" is a type of "safety toe." The real question is how traditional steel toes compare to their modern, non-metallic counterparts known as composite toes. Neither is universally better; the right choice depends entirely on your specific job hazards, environment, and personal needs.

The decision between steel and composite safety toes is a fundamental trade-off: Steel offers the maximum level of impact and compression protection, while composite provides superior comfort, lighter weight, and better performance in specialized environments.

What Defines a Safety Toe?

Before comparing materials, it's crucial to understand the standard they must meet. Both steel and composite toe caps are designed to protect you from workplace hazards.

The ASTM Safety Standard

Any legitimate safety boot in the United States must meet standards set by the American Society for Testing and Materials (ASTM). The relevant standard, ASTM F2413, specifies the minimum performance requirements for impact and compression resistance.

Steel Toe: The Traditional Protector

A steel toe cap is the classic solution for protective footwear. It is a heavy-duty steel cup built into the boot that provides robust protection against falling objects and crushing forces.

Composite Toe: The Modern Alternative

Composite toes are made from strong, non-metallic materials. These can include Kevlar, carbon fiber, plastic, or fiberglass. They are engineered to meet the same ASTM safety standards as steel toes but with a different set of properties.

Head-to-Head Comparison: Steel vs. Composite

Your choice will hinge on how you prioritize protection, comfort, and environmental factors. Each material has clear advantages in different categories.

Impact and Compression Protection

Steel is the definitive winner for raw protective strength. Steel toe caps can typically withstand higher levels of impact and compression than composite materials, making them the standard for heavy industrial and construction sites.

Weight and All-Day Comfort

Composite toes have a significant advantage here. Being made of lighter materials, they reduce the overall weight of the boot, which lessens foot fatigue over a long workday.

Performance in Extreme Temperatures

Composite materials do not conduct heat or cold easily. This makes composite toes far superior for work environments with extreme temperatures, as they provide better insulation and keep your feet more comfortable.

Workplace and Security Needs

If your job requires you to pass through metal detectors frequently, composite toes are the clear choice. Because they contain no metal, they won't set off security scanners.

Understanding the Trade-offs and Requirements

Choosing the wrong boot can lead to unnecessary discomfort or non-compliance with site safety rules.

The Importance of Site Mandates

Some job sites have long-standing safety policies that explicitly require steel toe boots. Before making a purchase, always verify your workplace's specific personal protective equipment (PPE) requirements.

Protection Beyond the Minimum

While both certified steel and composite toes meet the ASTM safety standard, steel often provides a higher ceiling for protection. It is more resistant to punctures, cuts, and abrasions beyond the basic impact tests.

Making the Right Choice for Your Role

Select your safety boot based on the primary demands of your job.

- If your primary focus is maximum impact protection: Choose steel toe boots, as they offer the highest resistance to crushing and compression forces.

- If your primary focus is all-day comfort and mobility: A lightweight composite toe boot will significantly reduce fatigue and strain.

- If your primary focus is working in extreme temperatures: Composite toes provide the insulation needed to keep your feet comfortable in severe heat or cold.

- If your primary focus is convenience and security clearance: A non-metallic composite toe is essential for passing through metal detectors without issue.

Choosing the right safety toe is about matching the tool to the task for optimal safety and performance.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Protection Level | Maximum impact/compression resistance | Meets ASTM safety standards |

| Weight & Comfort | Heavier, can cause fatigue | Lighter, reduces all-day fatigue |

| Temperature Performance | Conducts heat/cold | Superior insulation in extremes |

| Metal Detectors | Will set off scanners | Passes through without issue |

| Ideal For | Heavy industrial sites, max protection | Long shifts, extreme temps, security sites |

Need the right safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. Whether your priority is maximum steel toe protection or the lightweight comfort of composite toes, we have the production capabilities to meet your needs.

Contact us today for durable, reliable footwear solutions tailored to your specific workplace hazards.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What factors should be checked when trying on safety shoes? Ensure Perfect Fit & Maximum Protection

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear

- What is the importance of wearing safety shoes in the workplace? Protect Your Team and Your Bottom Line

- What types of safety shoes are appropriate for different work environments? Choose the Right Protection for Your Job

- What are the key safety features to consider when choosing work boots? Ensure Maximum Protection for Your Job