First, I need to understand what the user truly wants. They're asking about composite toe cap materials, but it's clear they're trying to figure out the best safety toe for their situation. I need to deliver more than just a list of materials; I need to provide a complete picture so they can choose with confidence.

I'll start with the surface question: What are the materials? The references tell me Kevlar, carbon fiber, fiberglass, and various plastics are used. But then I'll immediately shift to the deeper need: Why are these materials important, and how do they stack up against other options? Steel and alloy toes are obviously relevant comparisons. I need to give them a framework for evaluating these choices, so they can make an informed decision for their needs.

I'll keep a calm, authoritative tone, using clear language and short paragraphs. I’ll make sure to highlight key trade-offs, like how composite toes are great for certain environments but may be less durable under repeated significant impacts. The ultimate goal is to give the user actionable advice.

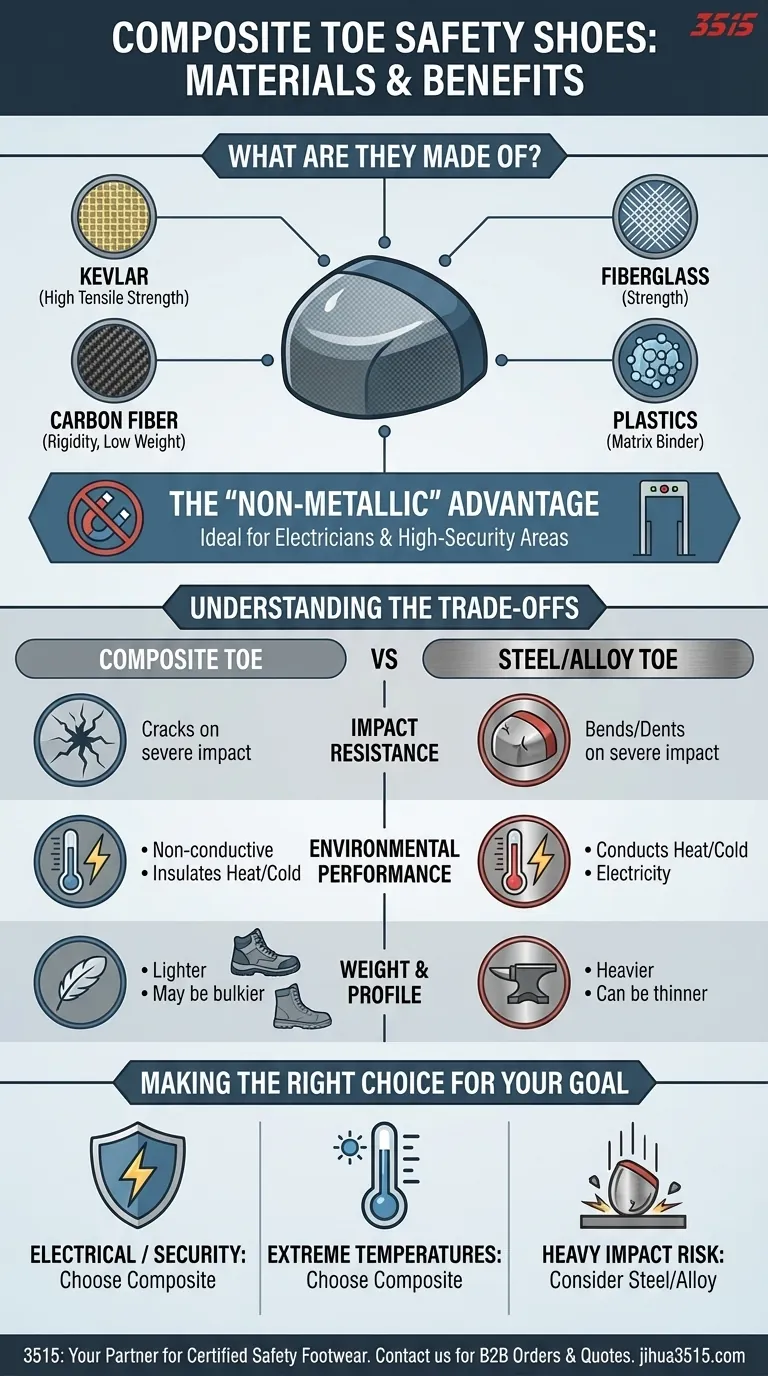

I’ll structure the response like this: First a clear, bold hook like "Composite safety toes are made from..." to answer the initial question. Then a takeaway that clearly frames the issue for the user. I’ll then dive into the details, outlining the materials, their pros and cons. I'll compare the options (steel, alloy, and composite), and finally, I'll end with a list of actionable advice, so they can determine which type of safety toe is best for their unique workplace. It's about providing the tools, the insights, so they can walk away with that solid feeling of knowing they have made the right choice. At their core, composite safety toes are protective caps made from a blend of non-metallic materials. The most common components used are Kevlar, a high-strength aramid fiber; carbon fiber, known for its rigidity and low weight; and fiberglass, a strong and cost-effective material. These are often combined with specialized plastics to create a lightweight protective shell.

The crucial insight is that composite toes are not simply a "better" version of steel toes; they are an alternative engineered for specific environments. Their value lies in their non-metallic and temperature-insulating properties, not necessarily in superior impact resistance.

How Composite Materials Redefine Foot Protection

To make an informed choice, it's essential to understand why these specific materials are used and how they fit into the overall structure of a safety shoe.

The Key Ingredients

The term "composite" means it's made of multiple constituent materials. In safety toes, these materials are chosen for their high strength-to-weight ratio.

- Kevlar: This synthetic fiber is famous for its use in ballistic vests. Its inclusion provides immense tensile strength and puncture resistance.

- Carbon Fiber: Extremely strong and rigid for its weight, carbon fiber provides the structural integrity needed to resist compression and impact.

- Fiberglass & Plastics: These materials often form the matrix that binds the advanced fibers together, providing a cost-effective way to achieve the required shape and durability.

The "Non-Metallic" Advantage

The defining characteristic of a composite toe is its complete absence of metal. This is not a minor detail; it is the primary reason for its existence.

This non-metallic nature makes composite toe footwear ideal for electricians and professionals working in high-security environments with metal detectors, such as airports or nuclear facilities.

It's Part of a System

The safety toe is just one component. A high-quality safety shoe integrates this cap with an upper (made of leather or synthetics), a durable outsole, a cushioning midsole, and a comfortable insole. The performance of the shoe depends on how well these parts work together.

Understanding the Trade-offs

Choosing a safety toe is a matter of weighing its advantages against its limitations for your specific work environment. There is no single "best" material.

Impact Resistance vs. Failure Point

All certified safety toes—whether composite, steel, or alloy—must meet the same ASTM F2413 safety standards for impact and compression.

However, they behave differently under extreme stress. A steel toe might bend or dent upon severe impact, while a composite toe is more likely to crack. For this reason, any safety shoe that has sustained a significant impact should be replaced immediately, as a composite toe's integrity could be compromised without visible damage.

Environmental Performance

This is where composite toes excel. Because they don't conduct electricity, they offer a secondary layer of protection for electricians.

Furthermore, they do not conduct temperature. In extreme cold or heat, a composite toe will not transfer the ambient temperature to your foot, providing a significant comfort advantage over steel.

Weight vs. Profile

Composite toes are significantly lighter than steel, which can reduce foot fatigue over a long workday.

The trade-off is often size. To achieve the same level of protection as a thin steel cap, a composite toe may need to be slightly bulkier or thicker in its design.

Making the Right Choice for Your Goal

Your work environment and daily tasks should be the deciding factors.

- If your primary focus is working around electricity or metal detectors: Composite is the definitive choice due to its non-conductive, non-metallic properties.

- If your primary focus is comfort in extreme temperatures: Composite offers superior insulation, preventing heat or cold from transferring to your feet.

- If your primary focus is working in an environment with frequent, heavy impact risk: While composite meets the standard, some users prefer the known durability of steel or alloy toes.

Understanding these material differences empowers you to select safety footwear that is not just compliant, but perfectly suited to your specific workplace demands.

Summary Table:

| Material | Key Property | Primary Benefit |

|---|---|---|

| Kevlar | High Tensile Strength | Puncture & Cut Resistance |

| Carbon Fiber | High Rigidity, Low Weight | Structural Integrity & Lightness |

| Fiberglass/Plastics | Cost-Effective Strength | Durability & Impact Resistance |

Need the right safety shoe for your workforce? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear with composite, steel, and alloy toes. We provide distributors, brand owners, and bulk clients with durable, comfortable boots tailored to specific workplace hazards—from electrical work to extreme temperatures. Let's discuss your requirements and get a quote for your next order.

Contact our expert team today to find the perfect safety solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- Where can safety shoes be purchased? A Guide to Finding the Right Supplier

- What are the main types of safety footwear? Choose the Right Protection for Your Workforce

- How do anti-slip outsoles and orthopedic heel designs contribute to footwear safety? Enhance Traction & Stability

- Why use steel surfaces for industrial footwear anti-slip testing? Ensuring Grip in High-Risk Environments

- How can you determine the right safety toe boot for your workplace? Match Boots to Hazards

- What role does simulation and prototype design software play in safety shoe manufacturing? Optimize Your Production

- What does OSHA 1910.136 state about safety footwear? A Guide to Compliance & Selection

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation