In essence, engineer boots are defined by their rugged, laceless design. They are a timeless piece of American workwear, recognizable by a tall leather shaft, a plain toe, and a system of adjustable straps with metal buckles at the ankle and top. Originally built for durability and protection, they have since become an icon for motorcyclists and fashion enthusiasts alike.

The core takeaway is that engineer boots represent a fusion of purpose-built function and iconic style. Their defining features—a laceless design with buckles, a tall protective shaft, and heavy-duty construction—are not merely aesthetic choices but are rooted in a history of providing maximum durability and protection.

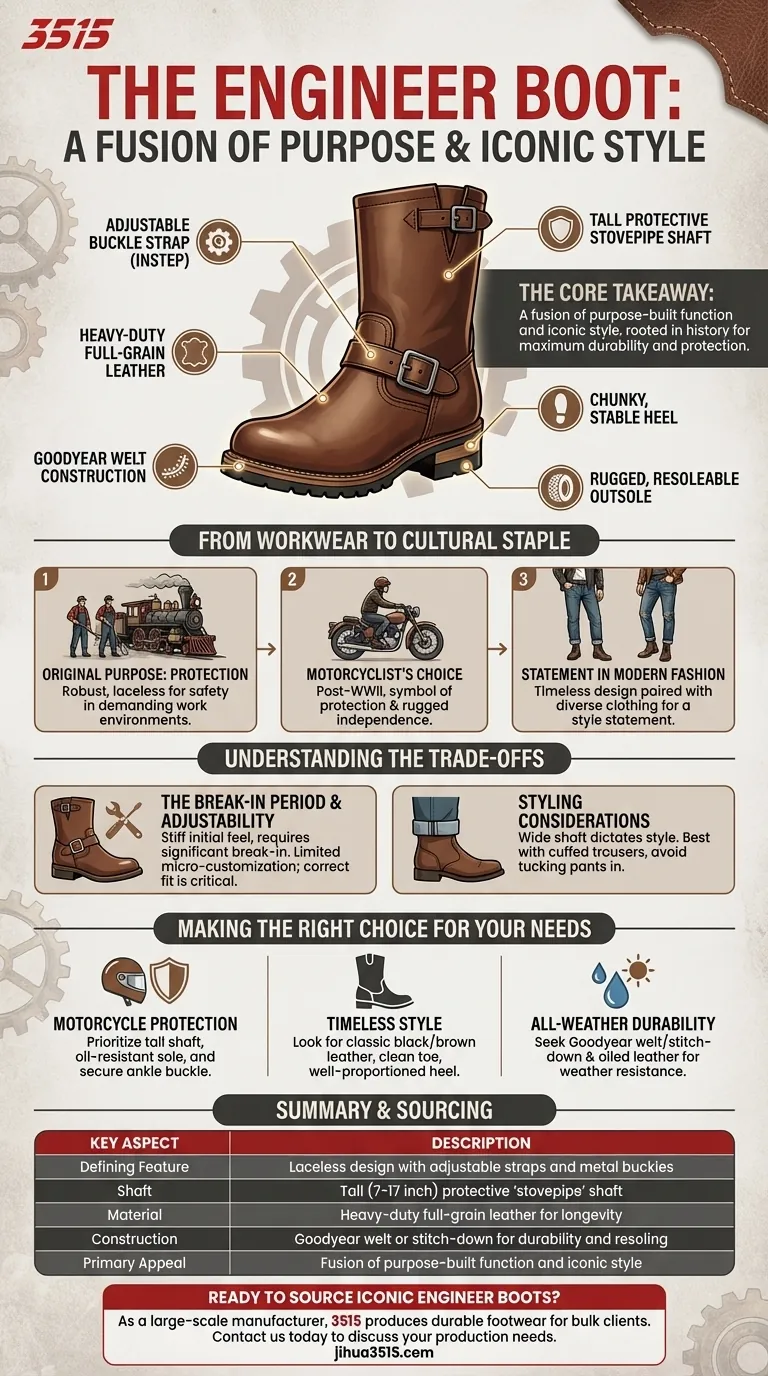

The Anatomy of an Icon: Deconstructing the Engineer Boot

To understand the appeal of the engineer boot, you must first understand its distinct components. Each feature serves a specific, practical purpose that contributes to its legendary resilience.

The Laceless, Buckled System

The most noticeable feature is the absence of laces. Instead, engineer boots use an adjustable leather strap and a metal buckle over the instep to secure the boot. A second buckle is often found at the top of the shaft, allowing for minor adjustments in calf fit.

This design choice eliminates the risk of laces getting caught in machinery or on a motorcycle's moving parts, offering a sleek and uninterrupted protective surface.

The Protective "Stovepipe" Shaft

Engineer boots feature a tall, double-layered shaft, often described as a "stovepipe" for its straight, cylindrical shape. The height typically ranges from 7 to 17 inches.

This tall shaft is designed to protect the wearer's shins from heat, debris, and impact—a key reason they were adopted by steam engine firemen and later, motorcyclists.

A Foundation of Full-Grain Leather

These boots are almost exclusively crafted from thick, heavy-duty full-grain leather, typically cowhide in black or brown. The leather is often oiled to enhance its flexibility and resistance to the elements. This material choice ensures longevity and allows the boot to develop a unique character over time.

The Rugged Sole and Heel

The foundation of the boot is just as important as its upper. They are traditionally built with a Goodyear welt or stitch-down construction, making them exceptionally durable and often resoleable.

The outsoles are thick, commonly made of leather or oil-resistant neoprene, providing a stable grip. The heel is typically chunky and substantial, usually around 1.5 inches high, providing support and a confident stance.

From Workwear to Cultural Staple

The engineer boot's journey from a purely functional item to a style icon highlights its inherent versatility and timeless design.

The Original Purpose: Protection

The boot's origins lie in demanding work environments. Its robust, laceless construction was ideal for workers who needed maximum protection without the hazard of loose laces.

The Motorcyclist's Choice

After World War II, the boot became synonymous with motorcycle culture. It offered riders unparalleled protection from engine heat, road debris, and potential accidents, all while projecting a rugged, independent image.

A Statement in Modern Fashion

Today, the engineer boot is a staple for those drawn to classic, durable design. Its clean lines and formidable presence allow it to be paired with everything from denim to wool trousers, transitioning from a functional tool to a deliberate style statement.

Understanding the Trade-offs

While iconic, engineer boots come with practical considerations that differ from standard laced footwear. Understanding these is key to appreciating them fully.

The Break-in Period

The thick, full-grain leather required for durability means that new engineer boots can be very stiff. A significant break-in period is often necessary for the leather to soften and mold to your foot.

Limited Adjustability

The buckle system offers some adjustment, but it cannot provide the same micro-customizable fit as a fully laced boot. Achieving the right fit from the start is therefore critical.

Styling Considerations

The boot's tall and wide shaft dictates certain style choices. They are best worn with trousers wide enough to fit over the shaft. Tucking pants into the boots is generally avoided; instead, cuffing them just above the opening showcases the boot's design.

Making the Right Choice for Your Needs

Selecting the right engineer boot depends entirely on your primary goal.

- If your primary focus is motorcycle protection: Prioritize a tall, thick leather shaft, oil-resistant soles, and a securely fastened ankle buckle for maximum safety.

- If your primary focus is timeless style: Look for a classic black or brown full-grain leather with a clean, rounded toe and a well-proportioned heel.

- If your primary focus is all-weather durability: Seek out boots with a Goodyear welt or stitch-down construction and oiled leather for enhanced weather resistance and longevity.

Ultimately, the engineer boot is a commitment to a piece of functional history that rewards you with unparalleled durability and character.

Summary Table:

| Key Aspect | Description |

|---|---|

| Defining Feature | Laceless design with adjustable straps and metal buckles |

| Shaft | Tall (7-17 inch) protective 'stovepipe' shaft |

| Material | Heavy-duty full-grain leather for longevity |

| Construction | Goodyear welt or stitch-down for durability and resoling |

| Primary Appeal | Fusion of purpose-built function and iconic style |

Ready to Source Iconic Engineer Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the classic engineer boot. We can help you bring this timeless piece of functional history to your customers with our commitment to quality and durability.

Contact us today to discuss your production needs and learn how we can be your trusted manufacturing partner.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the different types of PVC work boots available? Find the Right Safety Boot for Your Job

- What makes chemical-resistant boots suitable for certain environments? Essential Protection for Hazardous Work

- What should be considered for comfort and fit in farming and gardening boots? Ensure Long-Term Endurance

- What elements contribute to the support of a work boot? Discover the Key Components for All-Day Comfort

- What should be considered when purchasing work boots? A Guide to Choosing the Right Protection

- What should workers consider when selecting comfortable work boots? Prioritize Material, Fit, and Safety

- Why is it important for women to wear work boots designed specifically for them? The Critical Safety & Fit Advantage

- What is the primary purpose of lace-to-toe boots? Achieve a Perfect, Customizable Fit