A truly rugged 10-inch boot is defined by an integrated system of materials and construction designed for maximum protection and durability in harsh environments. Its key features include waterproof full-grain leather combined with durable nylon, a robust welt or bonded construction, a stability-enhancing shank, and a rugged lug outsole engineered for superior traction.

The most effective rugged boots are not just a collection of tough parts; they are a purpose-built system where the materials, construction, and internal support features work in concert to protect you from the environment while minimizing fatigue.

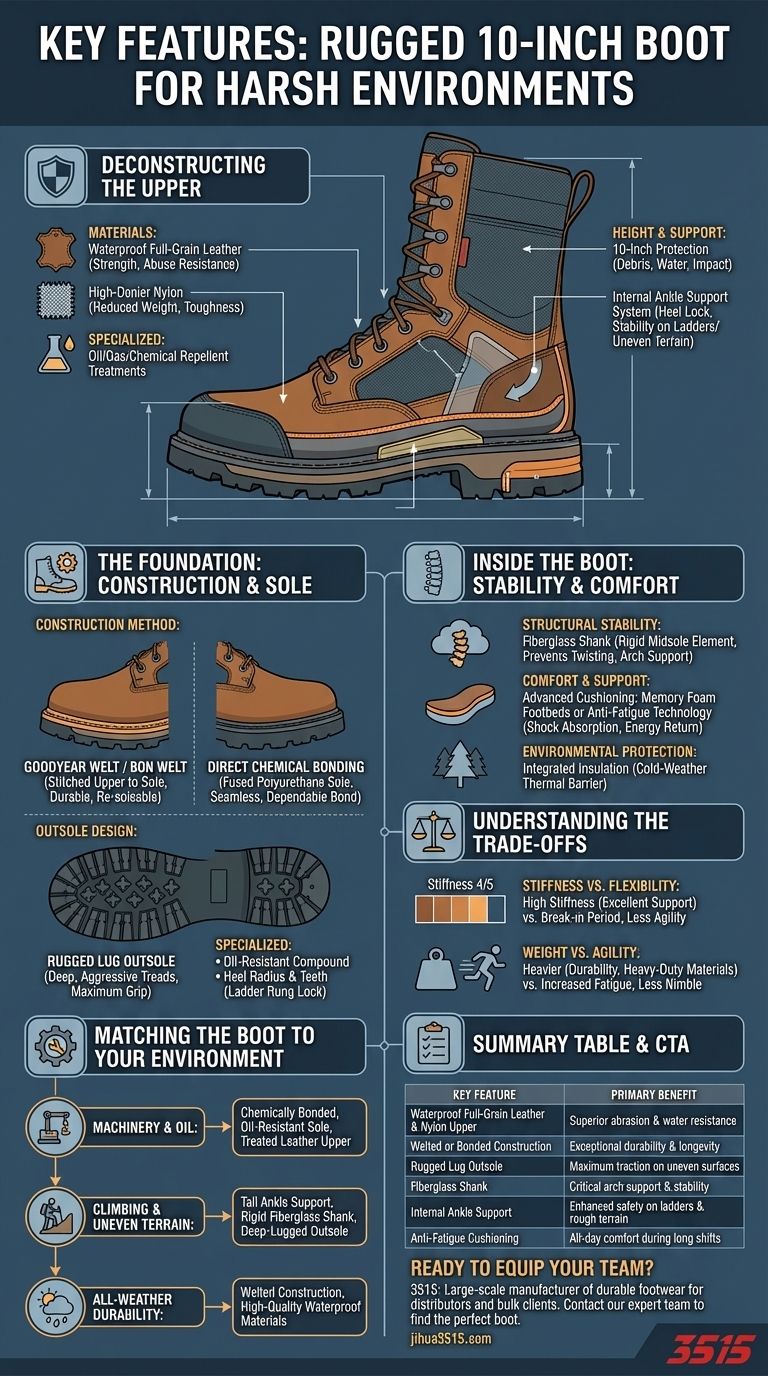

Deconstructing the Upper: Your First Line of Defense

The upper portion of the boot is your primary shield against environmental hazards. Its design and materials dictate its resistance to water, chemicals, and abrasion.

Material Selection for Durability

The primary material is typically waterproof full-grain leather, chosen for its inherent strength and ability to withstand abuse. This is often supplemented with panels of high-denier nylon to reduce weight without compromising toughness.

For specialized industrial settings, leathers are often specially treated to repel oil, gas, and other chemicals, providing significantly better abrasion resistance than standard leather.

The Importance of Height and Support

A 10-inch height provides substantial protection above the ankle from debris, water, and impacts.

This height works with internal ankle support systems to lock the heel in place, providing critical stability when climbing ladders or traversing steep, uneven terrain with a heavy load.

The Foundation: Construction and Sole Technology

How the boot is held together and what meets the ground are the most critical factors for longevity and safety. The sole and its construction method are the boot's functional foundation.

Construction Method: Welt vs. Bond

Many high-end rugged boots use a Goodyear welt or bon welt construction. This method involves stitching the upper to the sole, creating an exceptionally durable and often re-soleable boot.

An alternative method is direct chemical bonding, where an oil-resistant polyurethane sole is fused directly to the upper. This creates a seamless, dependable bond that prevents separation.

Outsole Design for Maximum Traction

A rugged lug outsole is standard, featuring deep, aggressive treads that provide excellent grip on mud, rock, and uneven surfaces.

Specialized designs may include an oil-resistant compound to prevent degradation and maintain traction on slick industrial surfaces. Some even feature a specific heel radius and teeth designed to securely lock onto ladder rungs, enhancing worksite safety.

Inside the Boot: Stability and Comfort

Protection from the outside is only half the battle. A boot's internal structure must provide stability and comfort to reduce fatigue over long hours of wear.

Structural Stability: The Shank

A fiberglass shank is a rigid piece embedded in the midsole, running from the heel to the ball of the foot.

This component acts like the chassis of a car, preventing the boot from twisting on uneven ground and providing crucial arch support. This drastically reduces strain on your feet during long periods of standing or walking.

All-Day Comfort and Support

To combat fatigue, these boots often incorporate advanced cushioning. This can include memory foam footbeds that conform to the shape of your foot or proprietary Anti-Fatigue technology designed to absorb shock and return energy.

Environmental Protection: Insulation

For cold-weather environments, integrated insulation is a key feature. It provides a thermal barrier to keep feet warm and functional in freezing temperatures without adding excessive bulk.

Understanding the Trade-offs

While these features create an exceptionally protective boot, they come with inherent trade-offs that are important to acknowledge.

Stiffness vs. Flexibility

The combination of thick leather, a rigid shank, and robust construction results in a very stiff boot, often with a stiffness rating of 4 out of 5.

This stiffness is excellent for support but requires a significant break-in period. It can also feel less agile than a lighter, more flexible boot.

Weight and Agility

Durability comes with weight. The heavy-duty materials and construction methods make these boots heavier than standard footwear.

This added weight can increase fatigue for users who need to cover long distances quickly, making it a trade-off between maximum protection and nimbleness.

Matching the Boot to Your Environment

Choosing the right features depends entirely on the specific demands of your environment and tasks.

- If your primary focus is working around machinery and oil: Prioritize a chemically bonded, oil-resistant sole and specially treated leather uppers.

- If your primary focus is climbing or navigating uneven terrain: Look for a tall ankle support system, a rigid fiberglass shank, and a deep-lugged outsole.

- If your primary focus is all-weather durability and protection: Emphasize a welted construction and high-quality waterproof materials for maximum longevity.

Ultimately, selecting the right rugged boot is about identifying the specific challenges you face and choosing the system of features best equipped to handle them.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Waterproof Full-Grain Leather & Nylon Upper | Superior abrasion & water resistance |

| Welted or Bonded Construction | Exceptional durability & longevity |

| Rugged Lug Outsole | Maximum traction on uneven surfaces |

| Fiberglass Shank | Critical arch support & stability |

| Internal Ankle Support | Enhanced safety on ladders & rough terrain |

| Anti-Fatigue Cushioning | All-day comfort during long shifts |

Ready to equip your team with boots built for the toughest jobs?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rugged boots and work shoes designed to meet the highest standards of safety and comfort.

Let us help you find the perfect boot for your specific environment and requirements. Contact our expert team today to discuss your needs and discover the 3515 advantage.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What is the purpose of a walking boot? A Guide to Safe and Effective Recovery

- Why are motorcycle boots considered essential gear? Unlock Superior Protection and Control

- What are the benefits of Wool or Shearling insulation in winter boots? Unbeatable Natural Warmth & Comfort

- What is the primary purpose of motorcycle boots? Essential Protection for Riders Explained

- What is the conclusion about the utility of snow boots? Essential Gear for Harsh Winter Conditions

- What are traction cleats, and when are they used? Master Winter Walking Safety

- What should be avoided when caring for tall boots? Prevent Costly Damage to Your Footwear

- Why are regular inspections important for trekking boots? Prevent Trail Failure with Proactive Gear Checks