Regular inspections are the most effective way to prevent trekking boot failure on the trail. This simple habit allows you to identify early signs of wear, like a peeling sole or damaged upper, and perform timely repairs before a minor issue becomes a trip-ending disaster.

Think of a boot inspection not as a chore, but as a critical safety and financial check. Identifying a small, fixable problem at home prevents a dangerous gear failure in a remote location and saves you from the high cost of a premature replacement.

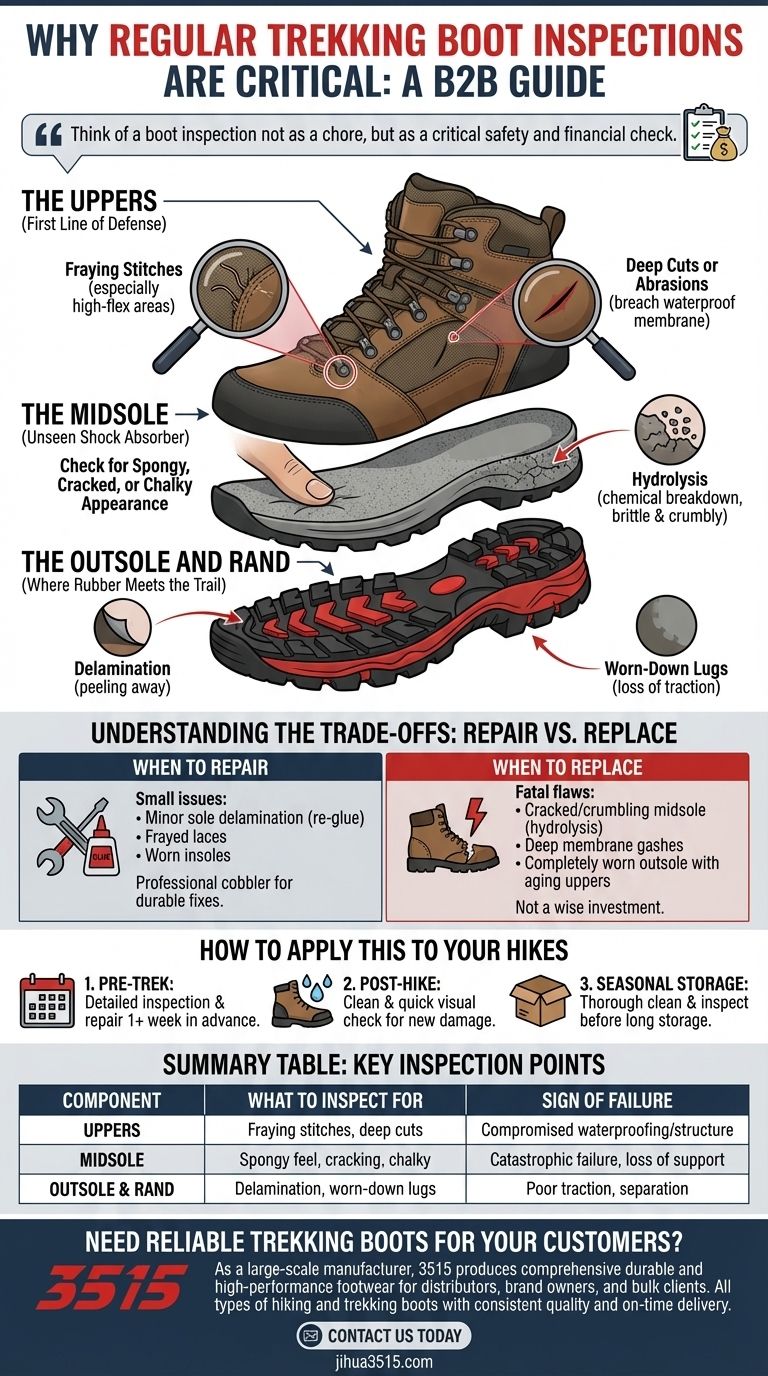

The Anatomy of a Boot Failure

A trekking boot is a complex system where the failure of one small part can compromise the entire structure. Regular checks help you understand how your boots are wearing and what needs attention.

The Uppers: Your First Line of Defense

The uppers are the main body of the boot, shielding your feet from the elements.

Look for fraying stitches, especially around high-flex areas near the ball of the foot. A single broken stitch can quickly unravel and compromise the boot's structure.

Also, examine the leather or synthetic fabric for deep cuts or abrasions that could breach the waterproof membrane.

The Midsole: The Unseen Shock Absorber

The midsole provides essential cushioning and support but is often where catastrophic, hidden failure occurs.

This layer is prone to hydrolysis, a slow chemical breakdown of the material (polyurethane) that makes it brittle and crumbly. This often happens in boots that are stored for long periods.

Press your thumb firmly into the side of the midsole. If it feels spongy, looks cracked, or has a chalky appearance, its integrity is gone. This is an almost certain sign of failure.

The Outsole and Rand: Where Rubber Meets the Trail

The outsole is your connection to the ground and a common point of failure.

Check for delamination, which is when the outsole begins to peel away from the rest of the boot, often starting at the toe or heel. This is a major structural problem.

Inspect the lugs (the tread). Once they are worn down, your boot loses its essential traction, creating a serious safety hazard on steep or wet terrain.

Understanding the Trade-offs: Repair vs. Replace

Knowing your gear means knowing when a repair is practical and when it's time to invest in a new pair. This objective assessment is key to both safety and financial responsibility.

When to Repair

Small issues caught early are almost always worth repairing. A professional cobbler can perform surprisingly durable fixes.

Minor sole delamination, especially at the toe, can be professionally re-glued. Frayed laces or worn-out insoles are simple, inexpensive replacements that can transform a boot's feel.

When to Replace

Some damage signals the end of a boot's safe, usable life.

A cracked or crumbling midsole due to hydrolysis is a fatal flaw. The boot's foundation is compromised and cannot be reliably repaired.

Likewise, deep gashes through the waterproof membrane or a completely worn-down outsole on a boot with aging uppers often mean the cost of repair is not a wise investment.

How to Apply This to Your Hikes

Integrate these checks into your hiking routine to make them second nature. A few minutes of prevention is worth hours of trouble on the trail.

- If you are preparing for a major trek: Perform a detailed inspection of the uppers, midsole, and outsole at least a week in advance to allow time for professional repairs.

- If you have just returned from a hike: Clean your boots and give them a quick visual check for any new cuts, separating seams, or peeling rubber.

- If you are storing your boots for the off-season: A thorough inspection and cleaning before storage prevents dirt from degrading materials and ensures they are ready for your next adventure.

Ultimately, proactive inspection turns your gear from a potential liability into your most reliable asset.

Summary Table:

| Boot Component | What to Inspect For | Sign of Failure |

|---|---|---|

| Uppers | Fraying stitches, deep cuts, abrasions | Compromised waterproofing, structural weakness |

| Midsole | Spongy feel, cracking, chalky appearance (hydrolysis) | Loss of cushioning and support; catastrophic failure |

| Outsole & Rand | Delamination (peeling), worn-down lugs | Poor traction, separation from the boot |

Need Reliable Trekking Boots for Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of hiking and trekking boots, ensuring consistent quality and on-time delivery for your business.

Contact us today to discuss your specific needs and let us become your trusted manufacturing partner.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

People Also Ask

- Why is rubber commonly used for non-slip soles? The Science of Superior Grip

- What types of rubber are typically employed in non-slip footwear soles? Your Guide to Maximum Grip and Safety

- How can footwear sole technology be upgraded to prevent entrapment risks? Engineering Safe, Anti-Snap Designs

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability