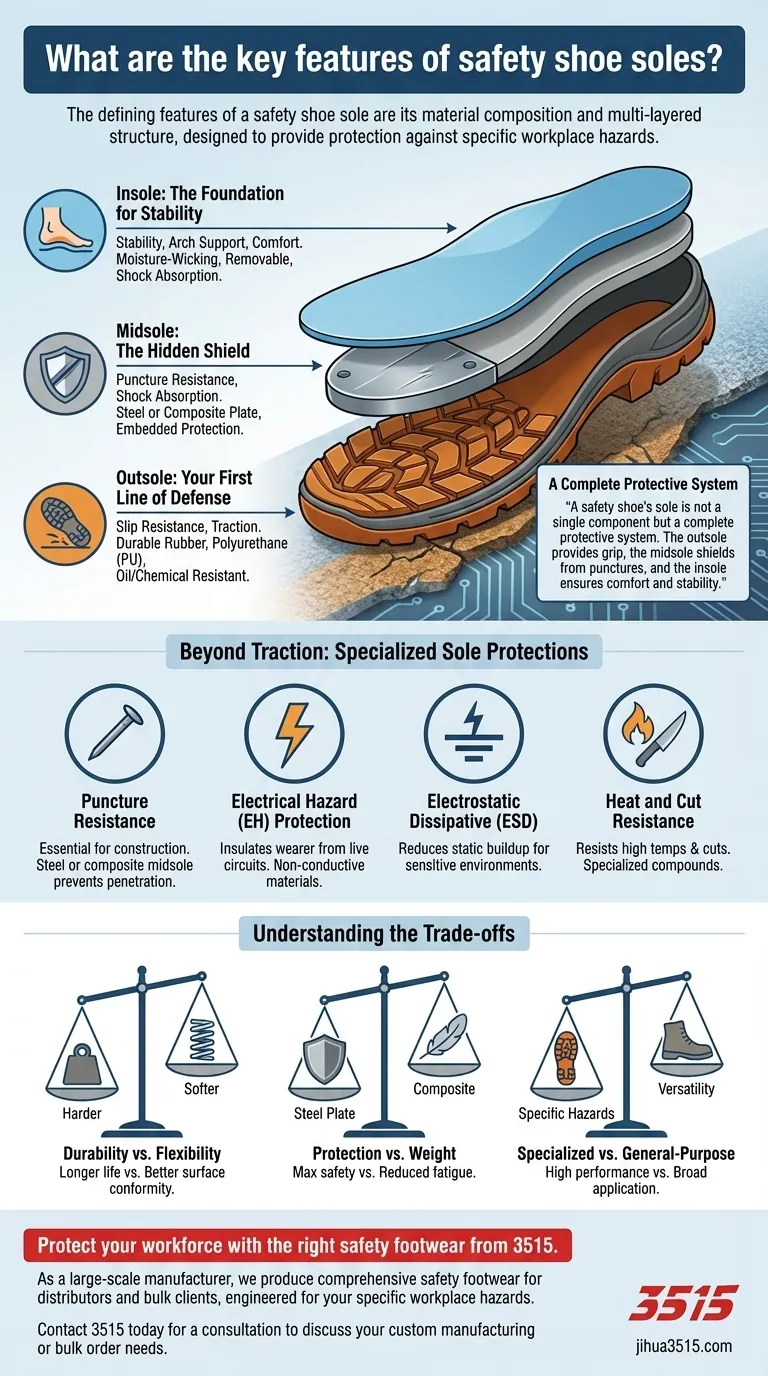

The defining features of a safety shoe sole are its material composition and multi-layered structure, designed to provide protection against specific workplace hazards. The most critical feature is a slip-resistant outsole made from durable rubber or polyurethane, which provides essential traction on slippery surfaces. However, a truly effective safety sole also incorporates a protective midsole for puncture resistance and a supportive insole for stability and comfort.

A safety shoe's sole is not a single component but a complete protective system. The outsole provides grip, the midsole shields from punctures, and the insole ensures comfort and stability. Understanding how these layers work together is key to selecting the right protection for your needs.

Deconstructing the Sole: A Three-Layer System

To truly understand a safety shoe sole, you must see it as three distinct layers working in concert. Each layer serves a specific function that contributes to overall safety and performance.

The Outsole: Your First Line of Defense

The outsole is the part of the shoe that makes direct contact with the ground. Its primary job is to prevent slips and falls.

Materials like durable rubber and polyurethane (PU) are chosen for their ability to provide superior traction on hazardous surfaces, including those contaminated with oil, water, or chemicals. The tread pattern is also engineered to channel liquids away from the point of contact.

The Midsole: The Hidden Shield

Located between the insole and the outsole, the midsole provides a crucial layer of underfoot protection.

Many safety shoes feature a steel or composite plate embedded in the midsole. This feature is designed to prevent sharp objects like nails or metal shards from puncturing the sole and injuring the foot. The midsole also contributes to shock absorption.

The Insole: The Foundation for Stability

The insole is the removable layer your foot rests on directly. Its role is often underestimated but is vital for both safety and long-term health.

A well-designed insole provides arch support, stability, and shock absorption, reducing fatigue during long shifts. It also prevents your foot from slipping inside the shoe, which can cause blisters and unnatural walking patterns. Many feature moisture-wicking properties to keep feet dry and inhibit bacterial growth.

Beyond Traction: Specialized Sole Protections

Depending on the work environment, a safety sole must do more than just prevent slips. Specialized properties are engineered into the sole's materials and construction to counter specific, high-risk hazards.

Puncture Resistance

As mentioned, this is typically achieved with a steel or composite midsole. It is an essential feature for construction sites, demolition zones, and any environment where sharp debris is present underfoot.

Electrical Hazard (EH) Protection

Soles with an EH rating are made from non-conductive materials that can insulate the wearer from the ground. This feature provides a secondary source of protection against accidental contact with live electrical circuits.

Electrostatic Dissipative (ESD) Properties

Distinct from EH protection, ESD soles are designed to reduce the buildup of static electricity from the body. This is critical in environments where a static discharge could damage sensitive electronic components or ignite flammable materials.

Heat and Cut Resistance

For environments like foundries, welding shops, or glass manufacturing, soles can be made from specialized rubber compounds. These materials are designed to resist high temperatures and provide protection against cuts from sharp materials.

Understanding the Trade-offs

Selecting the ideal safety sole involves balancing competing priorities. No single shoe is perfect for every situation, and understanding the inherent trade-offs is crucial for making an informed decision.

Durability vs. Flexibility

Harder sole compounds generally offer greater resistance to wear and tear, extending the life of the shoe. However, they are often stiffer and may provide less grip than a softer, more flexible material that can better conform to surface irregularities.

Protection vs. Weight

Features like steel puncture-resistant plates offer maximum protection but add significant weight and rigidity to the shoe. Lighter composite materials can reduce fatigue but may be bulkier or more expensive.

Specialized vs. General-Purpose

A sole with a tread pattern designed for shedding mud on uneven terrain may be less effective on a smooth, oily concrete floor. Choosing a highly specialized sole means it may underperform outside its intended environment.

Selecting the Right Sole for Your Environment

Your choice should be dictated entirely by the specific hazards you face in your daily work.

- If your primary focus is preventing slips on wet or oily surfaces: Prioritize a sole with a high slip-resistance rating and a tread pattern designed to channel away liquids.

- If your primary focus is protection from sharp objects: Ensure the shoe has a puncture-resistant midsole, made from either steel or a flexible composite material.

- If your primary focus is working near live electrical circuits: You must select a sole with an Electrical Hazard (EH) rating to provide critical insulation.

- If your primary focus is preventing static discharge in sensitive environments: Look for shoes with Electrostatic Dissipative (ESD) properties to safely ground static buildup.

By understanding the sole as a complete system, you can move beyond simple compliance and choose footwear that provides true, functional safety for your specific tasks.

Summary Table:

| Feature | Function | Key Materials & Properties |

|---|---|---|

| Outsole | Slip Resistance, Traction | Durable Rubber, Polyurethane (PU), Oil/Chemical Resistant |

| Midsole | Puncture Resistance, Shock Absorption | Steel or Composite Plate, Embedded Protection |

| Insole | Stability, Arch Support, Comfort | Moisture-Wicking, Removable, Shock Absorption |

| Specialized | EH/ESD, Heat/Cut Resistance | Non-Conductive, Static-Dissipative, Heat-Resistant Compounds |

Protect your workforce with the right safety footwear from 3515.

As a large-scale manufacturer, we produce a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring every sole is engineered for your specific workplace hazards—from superior slip resistance to certified EH/ESD protection.

Let us help you equip your team with durable, comfortable, and fully compliant safety shoes.

Contact 3515 today for a consultation to discuss your custom manufacturing or bulk order needs.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How to choose the right work boot? Match Safety Features to Your Job's Hazards

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- What are the main types of safety toe boots? A Guide to Steel, Composite & Alloy Toes

- What types of workplaces are steel toe boots traditionally used in? Essential Foot Protection for Hazardous Jobs

- Are steel toe and composite toe shoes the only safety shoe options? Discover the third type.