At their core, Rigmaster boots are engineered for harsh industrial environments through a combination of chemically resistant materials, specialized safety features for vertical work, and a uniquely durable construction. They prioritize protection from oil, gas, and water while incorporating features designed for the specific physical challenges of a rig or plant, such as climbing ladders and standing for long shifts.

The key differentiator of Rigmaster boots is not just their durability, but their design as a complete safety system. Every feature, from the chemically bonded sole to the ladder-gripping heel, is a direct solution to a specific hazard found in oil, gas, and heavy industrial worksites.

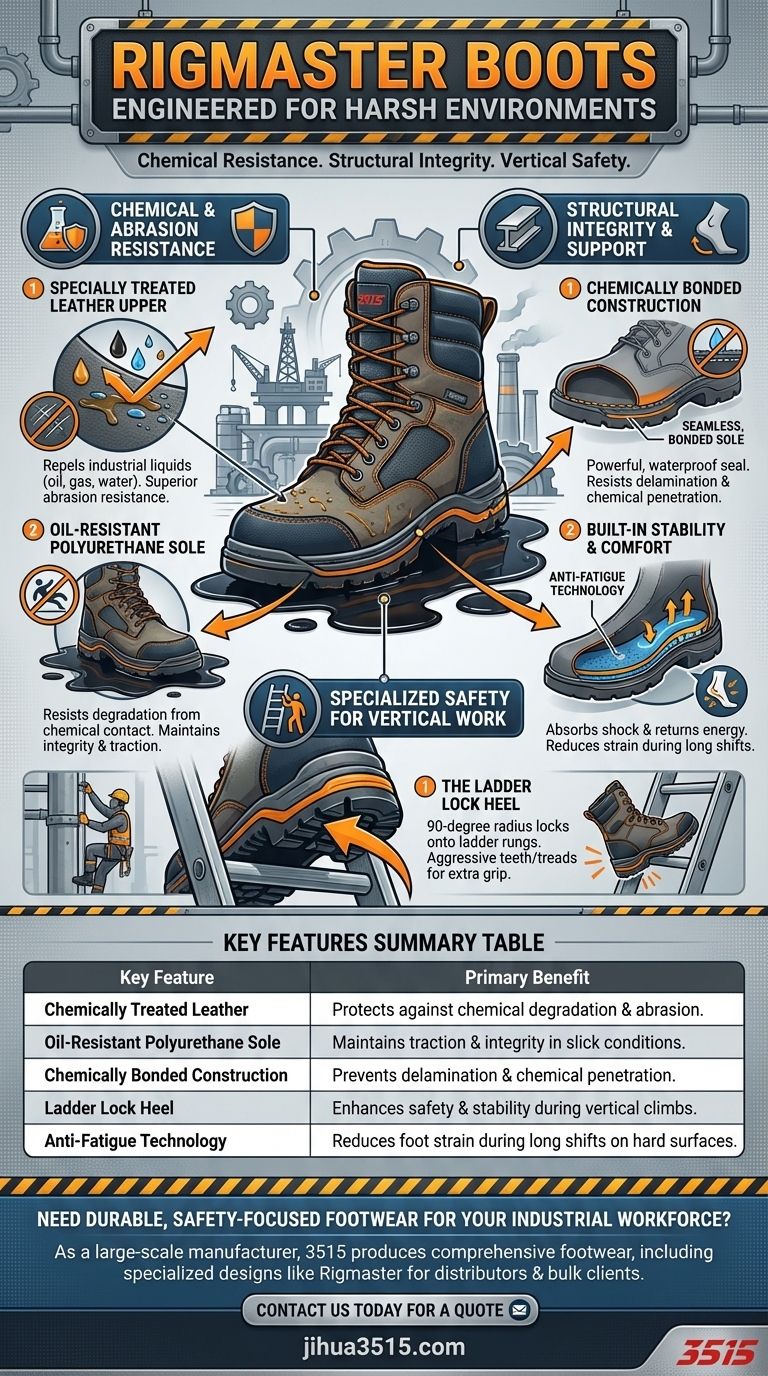

Engineered for Chemical and Abrasion Resistance

In environments dominated by hydrocarbons and abrasive surfaces, material selection is the first line of defense. Rigmaster boots address this with a two-part material strategy.

Specially Treated Leather Upper

The upper part of the boot is made from leather that has been specially treated to repel common industrial liquids. This treatment makes the material resistant to oil, gas, and water, preventing them from soaking in and degrading the leather over time.

This also provides superior abrasion resistance compared to standard leather, protecting against scuffs and cuts from equipment and rough surfaces.

Oil-Resistant Polyurethane Sole

The outsole is made from a polyurethane compound specifically formulated to resist degradation from contact with oils and chemicals. This ensures the sole maintains its integrity and traction, preventing it from becoming soft or brittle, which could lead to slips and falls.

A Focus on Structural Integrity and Support

A boot's construction method determines its durability and how it supports the foot under stress. Rigmaster's design emphasizes a seamless, stable platform.

Chemically Bonded Construction

Unlike boots with stitched welts, the Rigmaster’s sole is chemically bonded directly to the upper. This creates a powerful, waterproof seal with no seams for chemicals to penetrate or threads to rot or break.

This method results in a dependable, integrated unit that resists delamination even under constant flexing and exposure to harsh substances.

Built-in Stability and Comfort

The design includes an Anti-Fatigue technology system to absorb shock and return energy to the foot. This is critical for reducing strain during long shifts on unforgiving surfaces like concrete or steel grating.

While offered in pull-on and lace-up styles, both provide significant ankle support to prevent twists and sprains on uneven terrain or when carrying heavy loads.

Specialized Safety for Vertical Work

One of the most distinct features of the Rigmaster line is its specific design for workers who frequently climb ladders and structures.

The Ladder Lock Heel

The heel of the boot is engineered with a specific 90-degree radius designed to lock securely onto standard ladder rungs.

Furthermore, the heel features aggressive teeth or treads that bite into the ladder rung, providing an extra layer of grip and preventing dangerous slips during ascent or descent.

Understanding the Trade-offs

No single boot design is perfect for every possible scenario. Understanding the inherent compromises in the Rigmaster's design is key to making an informed decision.

Construction Method: Bonded vs. Welted

The chemically bonded sole offers superior waterproofing and chemical resistance. However, this construction method typically means the boot cannot be resoled, limiting its lifespan if the sole wears out before the upper.

In contrast, a traditional Goodyear Welt construction is highly durable and allows for resoling, but the stitched seams can be a potential point of failure for chemical penetration or thread rot if not properly maintained.

Material Focus: Specialized vs. General

Rigmaster's focus on oil- and gas-resistant leather is ideal for its target environment. However, for work in different conditions, such as those requiring extreme breathability or lighter weight, boots made with a combination of leather and synthetic materials like denier nylon might offer advantages.

Making the Right Choice for Your Environment

Your specific job site hazards should be the deciding factor.

- If your primary focus is working around oil, gas, and chemicals: The combination of the treated leather upper and the chemically bonded, oil-resistant sole provides the highest level of protection.

- If your primary focus is safety while climbing ladders or structures: The Ladder Lock heel is a non-negotiable feature designed specifically to mitigate the risk of falling from height.

- If your primary focus is durability and comfort on hard, flat surfaces: The Anti-Fatigue technology and seamless bonded construction are engineered to reduce wear on both the boot and your body.

Ultimately, choosing Rigmaster boots is a decision to invest in a specialized piece of safety equipment tailored to the unique risks of industrial work.

Summary Table:

| Key Feature | Description | Primary Benefit |

|---|---|---|

| Chemically Treated Leather | Oil, gas, and water-resistant upper material. | Protects against chemical degradation and abrasion. |

| Oil-Resistant Polyurethane Sole | Sole designed to resist degradation from oils and chemicals. | Maintains traction and integrity in slick conditions. |

| Chemically Bonded Construction | Sole bonded to the upper for a seamless, waterproof seal. | Prevents delamination and chemical penetration. |

| Ladder Lock Heel | 90-degree radius heel with gripping teeth for ladder rungs. | Enhances safety and stability during vertical climbs. |

| Anti-Fatigue Technology | Shock-absorbing footbed that returns energy. | Reduces foot strain during long shifts on hard surfaces. |

Need durable, safety-focused footwear for your industrial workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial shoes and boots, including specialized designs like the Rigmaster. We can provide the reliable, high-performance footwear your team needs to stay safe and productive in harsh environments.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why are some brands moving away from temperature ratings for winter boots? Understand True Warmth for Your Needs

- What are the characteristics of wildland fire boots? A Guide to NFPA-Certified Safety & Performance

- Can insulated work boots be worn in warmer weather? Avoid Discomfort and Foot Health Risks

- What are the advantages of PVC work boots? Get Essential Protection at a Lower Cost

- What is the price range for high-quality, durable construction boots? Find the Perfect Fit for Your Budget

- What factors should be considered beyond safety standards when choosing work boots? Ensure All-Day Comfort & Durability

- What additional safety features can be found in Chemical Resistant boots? Essential Multi-Hazard Protection

- What features should concrete workers look for in work boots? Essential Protection for Harsh Environments