In concrete work, the ideal boot combines a waterproof, chemical-resistant upper with a composite safety toe, superior cushioning for hard surfaces, and a high-traction, slip-resistant outsole. These features are non-negotiable for protecting you from the unique chemical and physical hazards of working with wet concrete and rebar all day.

Choosing a work boot for concrete is not just about meeting a safety standard; it's about investing in a specialized tool. The primary challenge is finding a boot that can withstand the corrosive, alkaline nature of wet concrete while providing the necessary support to prevent fatigue and injury from long hours on unyielding surfaces.

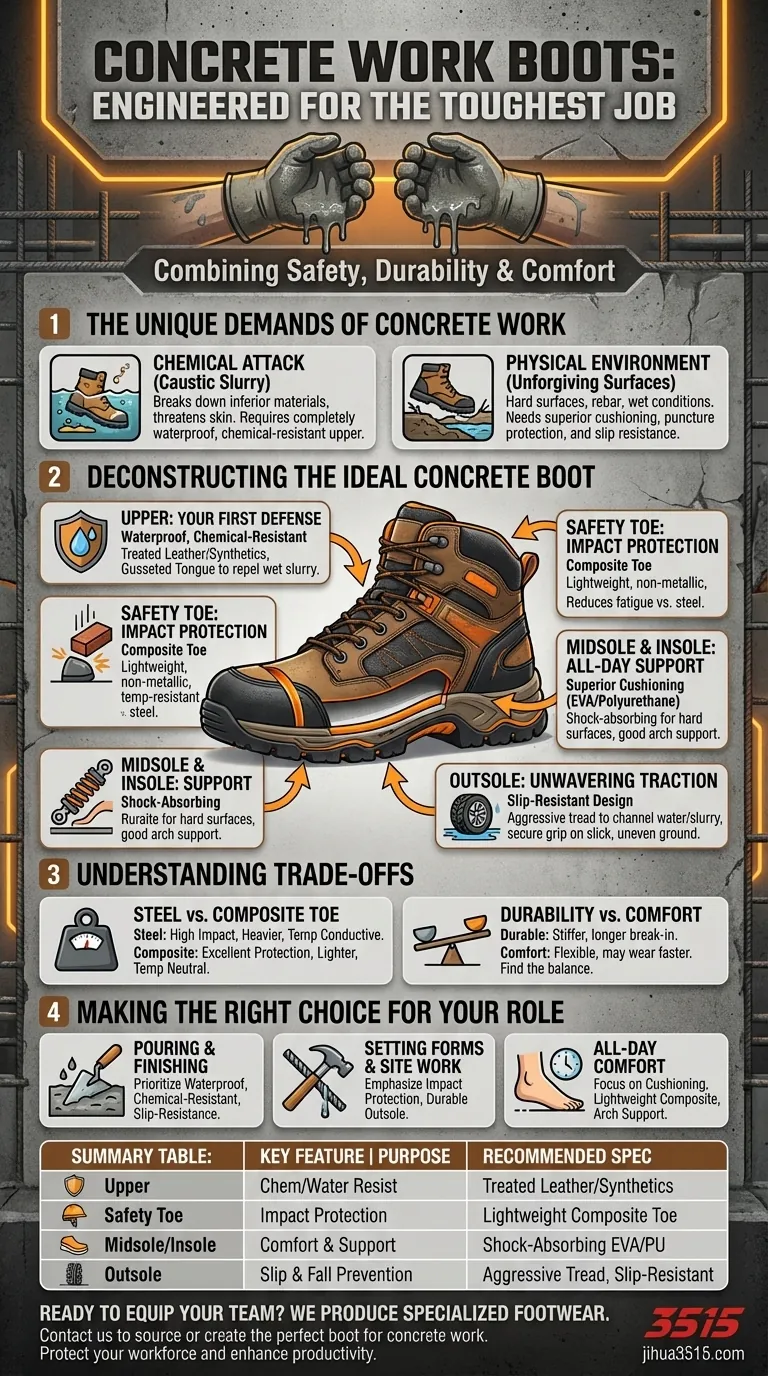

The Unique Demands of Concrete Work

Working with concrete presents a set of challenges that are fundamentally different from other construction trades. The footwear you choose must be specifically equipped to handle this environment.

The Chemical Attack

Wet concrete is not just mud and water; it is a highly alkaline chemical slurry. This caustic material actively breaks down leather and inferior synthetic materials, causing them to dry, crack, and fail prematurely.

This chemical exposure is also a direct threat to your skin, making a completely sealed and resistant boot an essential piece of personal protective equipment (PPE).

The Physical Environment

Concrete work involves standing for hours on hard, unforgiving surfaces, often peppered with rebar and uneven terrain. This requires a boot that can absorb shock, provide stability, and protect your feet from punctures and impacts.

Furthermore, the constant presence of water and wet slurry makes slips a significant risk, demanding an outsole designed for maximum traction in slick conditions.

Deconstructing the Ideal Concrete Boot

To meet these demands, you must evaluate a boot based on four critical components, each serving a distinct purpose.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. For concrete, it must be both waterproof and chemical-resistant. Look for boots made from high-quality, treated leather or advanced synthetic materials designed to repel alkaline substances.

A gusseted tongue—one that is attached to the boot on both sides—is also critical for preventing wet concrete from seeping in through the laces.

The Safety Toe: Impact Protection

A safety toe is essential for protection against falling materials and equipment. While steel toes are common, a composite toe is often the superior choice for concrete work.

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are significantly lighter than steel, which reduces fatigue over a long day, and they do not conduct heat or cold—a major advantage in extreme weather conditions.

The Midsole and Insole: All-Day Support

The midsole and insole provide cushioning and arch support. Given that you will be on your feet on hard surfaces all day, this is crucial for preventing foot, knee, and back pain.

Look for boots with thick, shock-absorbing midsoles made of materials like EVA or polyurethane. Good arch support is also vital for proper foot alignment and stability. Many professionals choose to add an aftermarket insole for customized comfort.

The Outsole: Unwavering Traction

The outsole is the point of contact with the ground. For concrete work, you need a slip-resistant design with a deep, aggressive tread pattern to channel away water and slurry.

This ensures a secure grip on slick, wet surfaces, rebar, and uneven ground, significantly reducing the risk of falls.

Understanding the Trade-offs

No single boot is perfect for every person or situation. Being aware of the key trade-offs will help you make a more informed decision.

Steel Toe vs. Composite Toe

Steel toes often offer the highest rating for impact resistance but come with a weight penalty and can become uncomfortably cold or hot in extreme temperatures.

Composite toes provide excellent protection that meets most safety standards while being lighter and impervious to temperature transfer. For most concrete applications, the benefits of a composite toe outweigh the marginal difference in impact rating.

Durability vs. Comfort

The most durable, "bomb-proof" boots are often heavier and stiffer, which can lead to a longer break-in period and potential fatigue.

Lighter, more flexible boots may offer greater comfort out of the box but might not withstand the chemical abuse of concrete for as long. The key is to find a balance that provides the necessary durability without sacrificing the comfort required for a 10-hour day.

Making the Right Choice for Your Role

Your specific tasks on the job site should guide your final decision.

- If your primary focus is pouring and finishing concrete: Prioritize a completely waterproof, chemical-resistant upper and excellent slip-resistance to handle constant exposure to wet slurry.

- If your primary focus is setting forms and general site work: Emphasize impact protection from a quality safety toe and a durable outsole that can withstand rebar and rough terrain.

- If your primary focus is all-day comfort and preventing fatigue: Invest in a boot with superior cushioning, a lightweight composite toe, and proper arch support.

Ultimately, the right work boot is an essential tool that protects your most valuable asset: your ability to work safely and effectively, day after day.

Summary Table:

| Key Feature | Purpose | Recommended Spec |

|---|---|---|

| Upper | Chemical & Water Resistance | Treated Leather / Advanced Synthetics, Gusseted Tongue |

| Safety Toe | Impact Protection | Lightweight Composite Toe (Non-Metallic) |

| Midsole/Insole | All-Day Comfort & Support | Shock-Absorbing EVA/Polyurethane, Good Arch Support |

| Outsole | Slip & Fall Prevention | Aggressive Tread, Slip-Resistant Design |

Ready to Equip Your Team with the Right Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, including models engineered specifically for the harsh demands of concrete work.

We can help you source or create the perfect boot that combines durability, comfort, and essential safety features. Protect your workforce and enhance productivity.

Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- What role do industrial safety shoes with steel toes or composite protective layers play in high-risk manufacturing?

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- What are the benefits of heavy duty work boots? Invest in Superior Safety & Durability

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety