At their core, the key features of a tactical boot's outsole are its material composition and its tread design. These elements are engineered to provide superior traction, stability, and durability across a wide range of unpredictable surfaces. This is achieved through specialized rubber compounds and aggressive, multi-directional lug patterns.

The outsole of a tactical boot is more than just a layer of rubber; it's a purpose-built system. The specific combination of material compound and lug geometry determines how the boot will perform, dictating its effectiveness on everything from wet pavement to loose gravel.

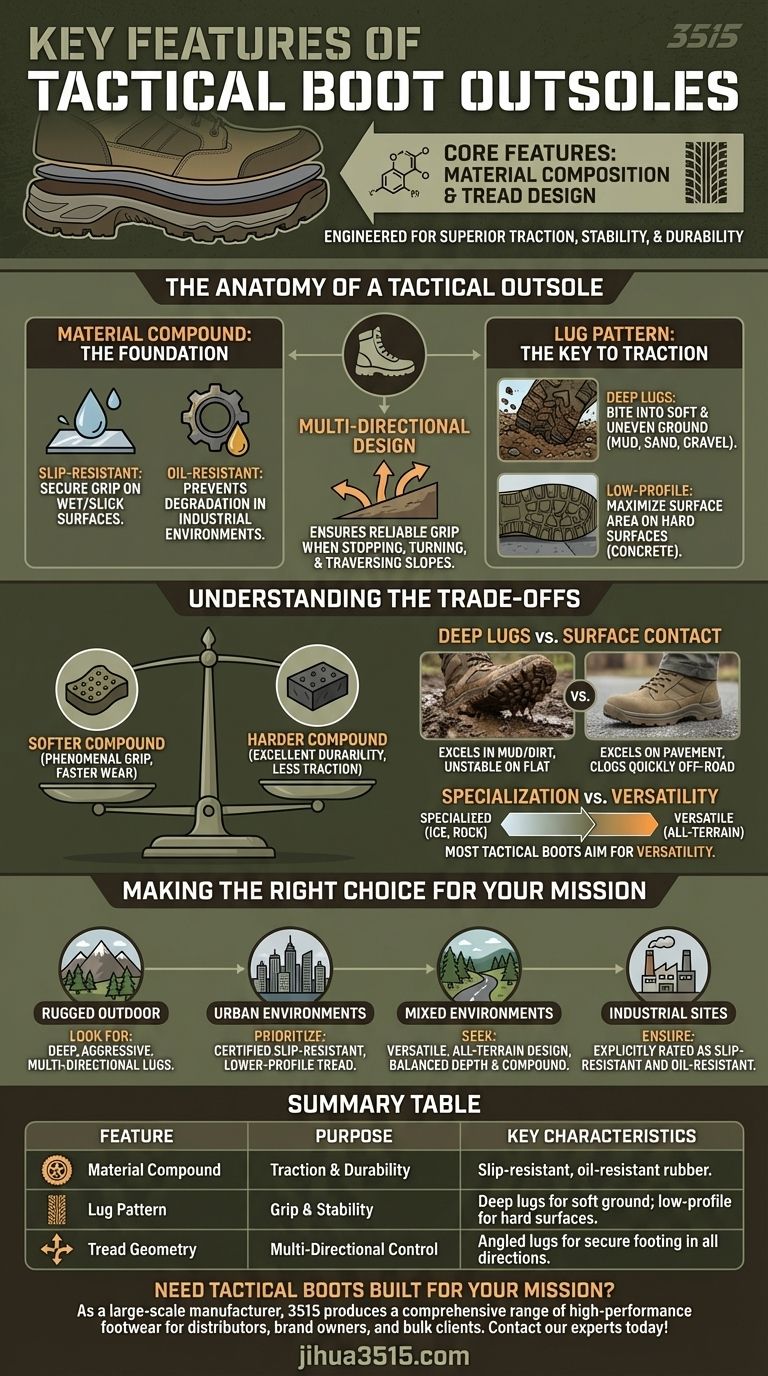

The Anatomy of a Tactical Outsole

To understand why tactical outsoles are so effective, you must look at their two primary components: the material itself and the physical design of the tread.

The Critical Role of the Material Compound

The foundation of any outsole is the rubber it's made from. In tactical boots, this isn't generic rubber; it's a compound specifically formulated for performance.

Many outsoles use a slip-resistant compound to maintain a secure grip on wet, slick, or oily surfaces. For industrial or mechanical environments, some are also explicitly rated as oil-resistant to prevent material degradation and maintain traction.

Lug Pattern: The Key to Traction

The most visible feature of an outsole is its lug pattern, also known as the tread. This pattern is not arbitrary; its design directly impacts grip and stability.

Deep lugs are designed to bite into soft and uneven ground like mud, sand, or gravel, providing excellent traction.

Conversely, patterns with broader, flatter contact points are more effective on hard, flat surfaces like concrete, maximizing the surface area for grip.

Geometry and Multi-Directional Design

Beyond depth, the orientation of the lugs is critical. Most tactical boots feature multi-directional lug patterns.

This design ensures reliable grip not just when moving forward, but also when stopping, turning, or traversing sloped terrain. It provides braking power on descents and secure footing on ascents.

Understanding the Trade-offs

Choosing an outsole always involves balancing competing demands. There is no single "best" design, only the best design for a specific application.

Grip vs. Durability

Softer rubber compounds offer phenomenal grip, especially on smooth, wet surfaces like rock. However, they wear down much faster, particularly on abrasive surfaces like pavement.

Harder rubber compounds provide excellent durability and longevity but may offer less traction on slick terrain.

Deep Lugs vs. Surface Contact

An outsole with deep, widely-spaced lugs excels in mud and loose dirt but can feel unstable on flat ground and will wear quickly.

A lower-profile outsole designed for urban use provides excellent surface contact on pavement but will quickly clog with mud and lose all traction in off-road conditions.

Specialization vs. Versatility

While some outsoles are highly specialized for conditions like ice or rock climbing, most tactical boots aim for versatility. They seek a balance that performs reliably across the widest possible range of terrains, even if it doesn't max out performance in any single one.

Making the Right Choice for Your Mission

Your intended environment should be the deciding factor when evaluating a boot's outsole.

- If your primary focus is rugged outdoor terrain: Look for an outsole with deep, aggressive, and multi-directional lugs for maximum grip on soft and uneven ground.

- If your primary focus is urban environments: Prioritize a certified slip-resistant compound with a lower-profile tread pattern that maximizes surface contact on concrete and asphalt.

- If your primary focus is a mix of environments: Seek a versatile, all-terrain design that balances moderate lug depth with a high-traction rubber compound.

- If your primary focus is industrial or hazardous sites: Ensure the outsole is explicitly rated as both slip-resistant and oil-resistant to meet safety standards.

By understanding these core features, you can look past marketing claims and select a boot with an outsole truly engineered for your specific operational needs.

Summary Table:

| Feature | Purpose | Key Characteristics |

|---|---|---|

| Material Compound | Traction & Durability | Slip-resistant, oil-resistant rubber for wet/oily surfaces. |

| Lug Pattern | Grip & Stability | Deep lugs for soft ground; low-profile for hard surfaces. |

| Tread Geometry | Multi-Directional Control | Angled lugs for secure footing when stopping, turning, or on slopes. |

Need tactical boots built for your mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical boots and shoes, engineered with the precise outsole features detailed above to ensure safety and reliability.

Let us help you equip your team with the right footwear. Contact our experts today to discuss your specific requirements and discover how we can deliver durable, high-traction solutions for your operational needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How should tactical boots fit? A Guide to Perfect Fit for Performance & Safety

- What are tactical footwear and their primary purpose? Engineered for Maximum Performance & Protection

- What are the characteristics of tactical boot outsoles? Ensure Unwavering Grip and Durability

- What factors should be considered when choosing boots for operations? A Guide to Mission-Ready Footwear

- What are the key features of classic jungle boots? Master the Design for Hot, Wet Environments

- What is the function of high-performance tactical boots in industrial communication failures? Ensure Rapid Response

- What technologies are used in the insoles of tactical shoes? Enhance Performance and Foot Health

- What makes tactical work boots a good choice for outdoor enthusiasts? Lightweight Agility Meets All-Weather Support