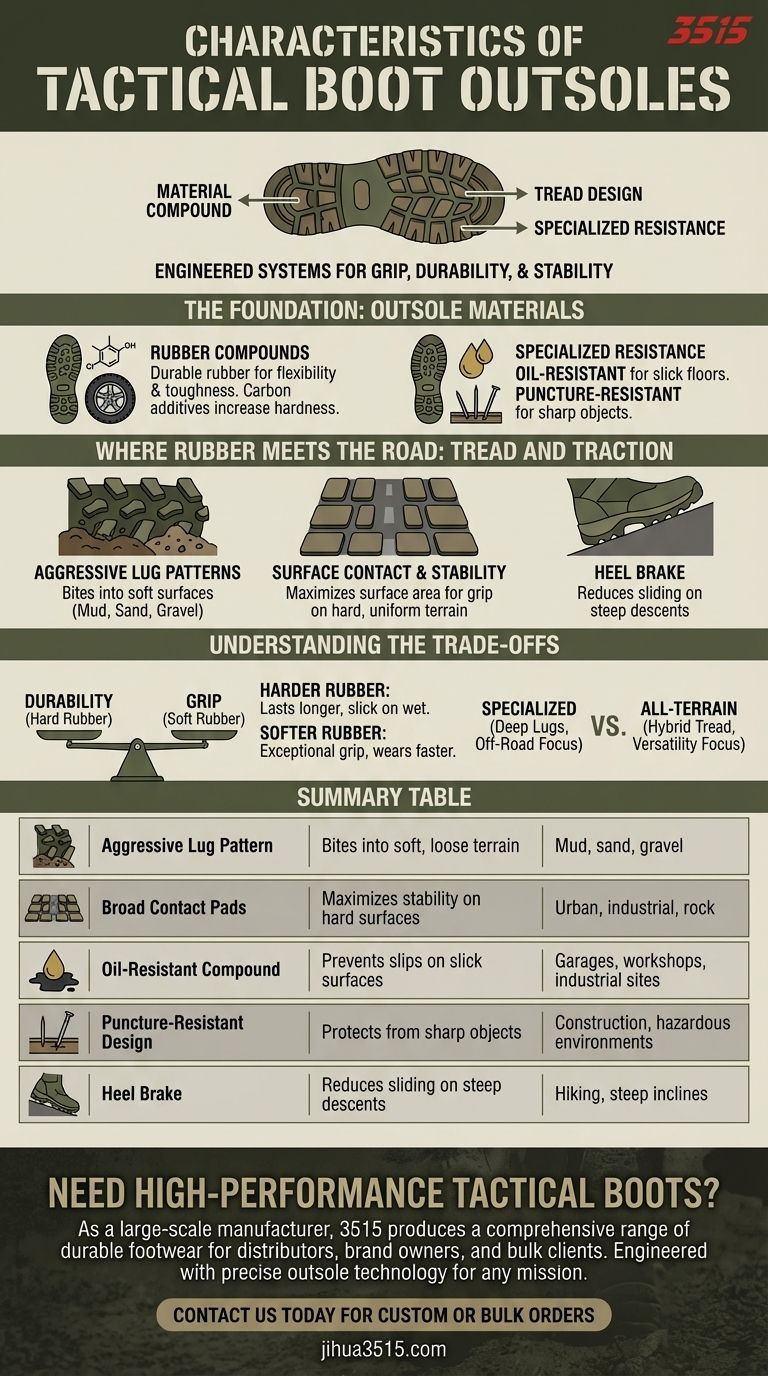

At their core, tactical boot outsoles are engineered systems designed for uncompromising grip, durability, and stability across a wide range of unpredictable surfaces. They are built from specialized rubber compounds and feature tread patterns specifically designed to handle everything from loose gravel and mud to slick, oily floors.

The most critical takeaway is that an outsole is not a single feature but a balance of three elements: its material compound, its tread design, and any specialized resistance properties. The ideal outsole is one where these three components are correctly matched to your most common operational environment.

The Foundation: Outsole Materials

The material composition of an outsole dictates its fundamental balance between durability and grip. This is the starting point for its overall performance.

The Role of Rubber Compounds

Nearly all tactical outsoles are made from durable rubber. This material provides an excellent combination of flexibility for movement and toughness for protection. Some formulas include additives like carbon to increase hardness and extend the life of the sole.

Specialized Resistance Properties

For specific environments, outsoles are treated or designed for enhanced resistance. Oil-resistant soles are crucial for industrial or garage settings to prevent slips, while puncture-resistant designs protect the foot from sharp objects on the ground.

Where Rubber Meets the Road: Tread and Traction

The pattern molded into the bottom of the outsole—the tread—is what provides traction. Its design is highly specific to the terrain it is meant to conquer.

Aggressive Lug Patterns

Lugs are the deep, protruding bumps on an outsole. Deep, aggressive lugs are designed to bite into soft or loose surfaces like mud, sand, and gravel, providing powerful traction where flat soles would fail.

Surface Contact and Stability

Conversely, outsoles designed for urban terrain, rock, or flat surfaces often feature broader, flatter pads. This design maximizes the surface area in contact with the ground, providing superior grip and stability on hard, uniform terrain.

The Function of a Heel Brake

Many tactical and hiking designs incorporate a heel brake. This is an abrupt, angled change in the tread pattern at the heel, designed to dig in and reduce the chance of sliding during steep descents.

Understanding the Trade-offs

Choosing an outsole is an exercise in prioritizing needs, as no single design excels in every situation. Understanding the inherent compromises is key to making an informed decision.

Durability vs. Grip

A fundamental trade-off exists between the hardness of the rubber and its grip. Harder rubber compounds offer superior durability and last much longer, but they can feel slick on smooth, wet surfaces. Softer rubber provides exceptional grip but will wear down more quickly.

Specialized vs. All-Terrain

An outsole with deep, widely-spaced lugs perfect for mud will feel clumsy and may offer less grip on smooth concrete. A boot designed for urban environments may quickly become clogged and ineffective in deep mud. You must identify your primary terrain.

Making the Right Choice for Your Mission

Your environment dictates the ideal outsole. Analyze your needs and match the boot's capabilities to the challenges you will face.

- If your primary focus is off-road and natural terrain: Prioritize a boot with deep, aggressive lugs that can bite into soft ground for maximum traction.

- If your primary focus is urban or industrial environments: Look for an outsole with broader contact pads for stability and certified oil-resistant properties.

- If your primary focus is all-purpose versatility: Seek a hybrid tread pattern that balances moderate lug depth with sufficient surface area for performance on both hard and soft ground.

Ultimately, choosing the right outsole ensures your footing is as reliable and secure as the rest of your gear.

Summary Table:

| Characteristic | Key Function | Ideal For |

|---|---|---|

| Aggressive Lug Pattern | Bites into soft, loose terrain | Mud, sand, gravel |

| Broad Contact Pads | Maximizes stability on hard surfaces | Urban, industrial, rock |

| Oil-Resistant Compound | Prevents slips on slick surfaces | Garages, workshops, industrial sites |

| Puncture-Resistant Design | Protects from sharp objects | Construction, hazardous environments |

| Heel Brake | Reduces sliding on steep descents | Hiking, steep inclines |

Need high-performance tactical boots built for your specific mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical boots and shoes, engineered with the precise outsole technology your operations demand—whether for rugged off-road use, urban stability, or specialized industrial safety.

Let us help you equip your team with reliable footing. Contact us today to discuss your custom or bulk order requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What features distinguish a tactical boot from regular boots? Uncover the Key Design Differences

- What should outdoor enthusiasts look for in tactical boots? Find the Perfect Balance of Traction & Support

- What safety standards should firefighting boots meet? NFPA 1971 Compliance for Maximum Protection

- How does breathability impact the comfort of tactical boots? The Key to Cool, Dry Feet

- What features do tactical boots typically have? A Guide to Rugged Durability & Performance

- Why are tactical boots necessary for complex terrains? Master Stability with Reinforced Support

- What are the three main types of tactical boots and their purposes? Choose the Right Boot for Your Mission

- What makes tactical work boots a good choice for outdoor enthusiasts? Lightweight Agility Meets All-Weather Support