Replacing safety boots is not about aesthetics; it's a critical safety protocol. Over time and with every use, the protective materials and structural integrity of your boots degrade. This process silently compromises their ability to shield you from serious workplace hazards, turning reliable protection into a potential liability.

The core issue isn't simply that boots get old, but that their most critical safety features can fail invisibly. Understanding the specific signs of degradation is the only way to ensure your footwear can perform its function when you need it most.

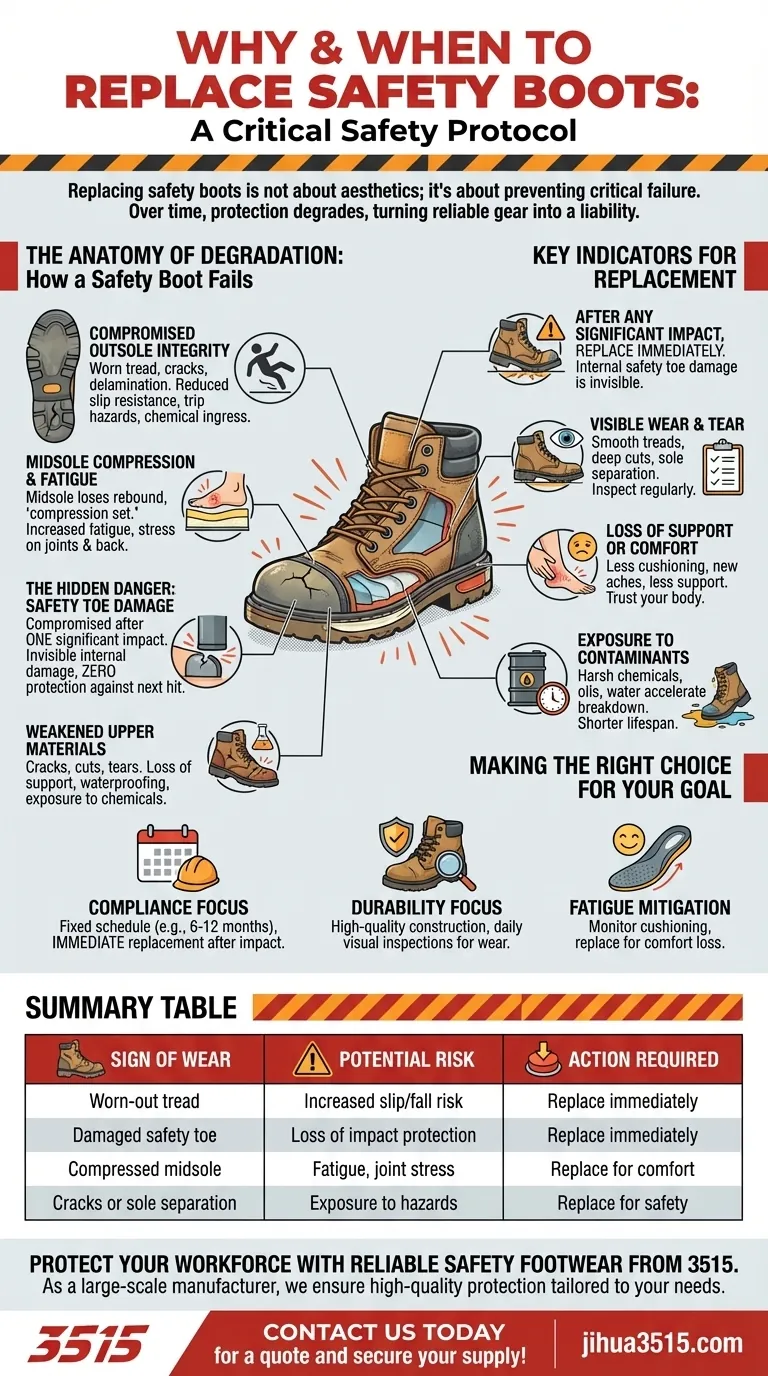

The Anatomy of Degradation: How a Safety Boot Fails

A safety boot is a complex system of components, each of which can fail in a different way. Wear and tear is not uniform, and damage to one part can compromise the entire boot.

Compromised Outsole Integrity

The outsole is your primary point of contact with the ground. Its tread is engineered for slip resistance on specific surfaces.

As the tread wears down, this slip resistance is dramatically reduced, significantly increasing the risk of slips, trips, and falls—one of the most common causes of workplace injuries.

Furthermore, cracks or splits in the sole can allow liquids, chemicals, or sharp objects to penetrate the boot, and delamination (where the sole separates from the upper) creates a critical trip hazard.

Midsole Compression and Fatigue

The midsole is the boot's shock absorber, typically made from materials like EVA foam or polyurethane. It's designed to cushion impact and reduce fatigue.

With every step, this material compresses. Over time, it loses its ability to rebound, a condition known as "compression set." A compacted midsole offers little to no shock absorption, leading to increased fatigue and long-term stress on your feet, ankles, knees, and back.

The Hidden Danger: Safety Toe Damage

The safety toe (whether steel, alloy, or composite) is designed to withstand a single, significant impact or compression event.

After such an event, the toe cap's structural integrity is compromised, even if there is no visible external damage. It will not provide its rated level of protection against a subsequent impact. This is the most critical and least visible form of failure.

Weakened Upper Materials

The "upper" is the material that covers your foot. In leather boots, a lack of cleaning and conditioning can cause the material to dry, crack, and lose its supportive structure.

For synthetic materials, cuts, tears, or abrasion can destroy waterproofing and expose the foot to chemical splashes or physical hazards.

Key Indicators for Replacement

Trusting a boot past its service life is a significant gamble. A proactive inspection routine is essential for identifying when a boot has become unsafe.

After Any Significant Impact

This is the most important rule. If a heavy object falls on the toe or the boot is subjected to a crushing force, it must be replaced immediately. The internal damage to the safety toe is invisible.

Visible Wear and Tear

Regularly inspect your boots for clear signs of failure. This includes worn-out, smooth treads, deep cuts or cracks in the upper or sole, and any separation between the sole and the rest of the boot.

Loss of Support or Comfort

Your body often notices failure before your eyes do. If a boot suddenly feels less supportive, the cushioning is gone, or it begins causing new aches and pains, its internal structure has likely broken down.

Exposure to Contaminants

Harsh chemicals, oils, and even excessive water can accelerate the breakdown of sole adhesives and upper materials. If your boots are constantly exposed to these elements, their lifespan will be shorter, regardless of physical wear.

Making the Right Choice for Your Goal

A proactive approach to your safety footwear is essential. Use your specific work environment and daily tasks to guide your replacement strategy.

- If your primary focus is compliance in a moderate-wear environment: Follow a fixed replacement schedule (e.g., every 6-12 months) and replace boots immediately after any significant impact.

- If your primary focus is durability in a demanding, high-wear job: Invest in high-quality boots with durable construction (like a Goodyear welt) and perform daily visual inspections for key failure points like tread depth and sole separation.

- If your primary focus is mitigating fatigue and joint stress: Pay close attention to midsole compression and replace boots as soon as you feel a noticeable loss of cushioning, even if the exterior still looks good.

Treating your safety boots as critical, consumable equipment is the foundation of a proactive safety culture.

Summary Table:

| Sign of Wear | Potential Risk | Action Required |

|---|---|---|

| Worn-out tread | Increased slip/fall risk | Replace immediately |

| Damaged safety toe | Loss of impact protection | Replace immediately |

| Compressed midsole | Fatigue, joint stress | Replace for comfort |

| Cracks or sole separation | Exposure to hazards | Replace for safety |

Protect your workforce with reliable safety footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of durable safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality protection tailored to your needs. Contact us today for a quote and secure your supply of dependable safety footwear!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do wildland firefighting boots differ from other firefighting boots? Key Design & Safety Differences

- What are the long-term benefits of proper firefighting boot selection? Ensure Career Longevity & Safety

- How does rebuildability extend the life of fire boots? Maximize Your Gear's Lifespan & ROI

- What advancements have been made in soft-toe boot design? From Durability to All-Day Comfort

- What is Stitch-down Construction in work boots? Discover the Ultimate Durability and Stability

- How does the fitting compare between pull-on and lace-up work boots? Convenience vs. Control

- Why do breeder farms need higher-spec protective boots? Ensure Biosecurity for High-Value Genetic Assets

- Why is it important to choose the right work-safe boots? Ensure Safety, Comfort, and Productivity