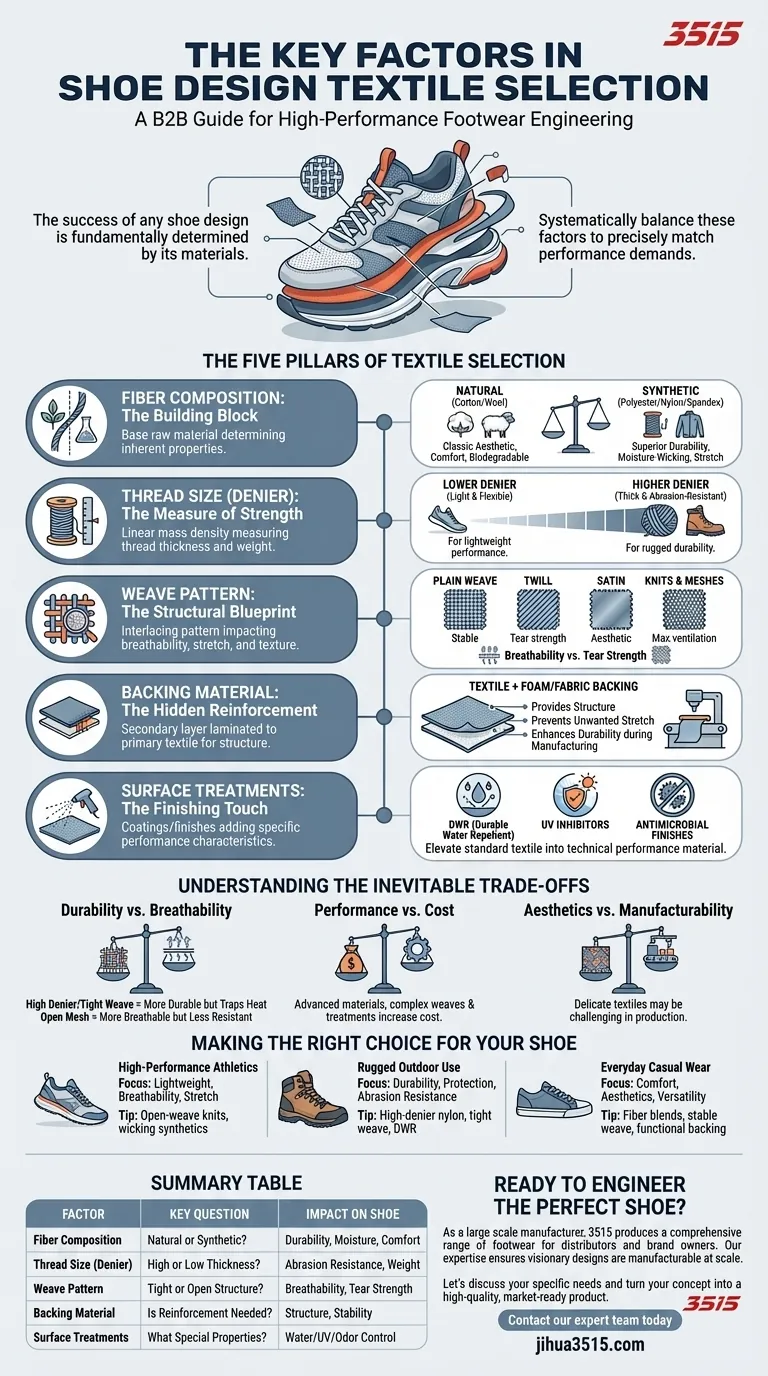

The success of any shoe design is fundamentally determined by its materials. When selecting textiles for footwear, your choice hinges on five critical factors: the fiber composition, the thread size (denier), the weave pattern, the backing material, and any applied surface treatments. These elements work in concert to dictate the shoe's final durability, performance, aesthetic, and ability to be manufactured at scale.

Choosing the right textile is not about finding a single "best" material. It is a process of systematically balancing these five core factors to precisely match the specific purpose and performance demands of the shoe you intend to create.

The Five Pillars of Textile Selection

Understanding how each component contributes to the final product is essential for moving from concept to a successful, functional shoe. These five pillars provide the framework for making an informed decision.

Fiber Composition: The Building Block

The fiber is the base raw material of your textile. It can be natural (like cotton or wool) or synthetic (like polyester, nylon, or spandex).

The choice of fiber dictates the inherent properties of the fabric, such as its moisture-wicking ability, durability, and hand-feel. Synthetics often provide superior durability and moisture management, while natural fibers can offer a classic aesthetic and comfort.

Thread Size (Denier): The Measure of Strength

Denier is a unit of measurement for the linear mass density of fibers. In simple terms, it tells you the thickness and weight of the thread.

A higher denier (e.g., 1000D Cordura nylon) results in a thicker, heavier, and more abrasion-resistant fabric, ideal for hiking boots or workwear. A lower denier creates a lighter, more flexible textile suited for running shoes or lightweight casuals.

Weave Pattern: The Structural Blueprint

The weave is the pattern in which threads are interlaced to form the fabric. Common patterns include plain weave, twill, and satin, while other structures like knits and meshes offer different properties.

The structure of the weave directly impacts the textile's breathability, stretch, and visual texture. An open-air mesh provides maximum ventilation, while a tight twill weave offers excellent tear strength.

Backing Material: The Hidden Reinforcement

Many footwear textiles are laminated with a backing material—a secondary layer of fabric or foam that is fused to the primary textile.

This unseen layer is critical for providing structure, preventing unwanted stretch during the lasting process, and enhancing overall durability. A stable backing ensures the shoe can withstand the strains of manufacturing without ripping or distorting.

Surface Treatments: The Finishing Touch

These are coatings and chemical finishes applied to the textile's surface to add specific performance characteristics that the base fabric lacks.

Common treatments include Durable Water Repellent (DWR) coatings for weather resistance, UV inhibitors to prevent fading from sunlight, and antimicrobial finishes to control odor. These treatments elevate a standard textile into a technical performance material.

Understanding the Inevitable Trade-offs

Material selection is never about maximizing one attribute; it is always an exercise in balancing competing needs. Being aware of these trade-offs is the mark of an experienced designer.

Durability vs. Breathability

There is often an inverse relationship between these two properties. A high-denier fabric with a very tight weave will be exceptionally durable and abrasion-resistant, but it will also trap heat and moisture. Conversely, an open-weave mesh is highly breathable but more susceptible to snags and tears.

Performance vs. Cost

Advanced materials come at a price. High-tech synthetic fibers, complex weaves, and specialized chemical treatments all add to the cost per yard of the textile. You must weigh the tangible performance benefits against the final target cost of the shoe.

Aesthetics vs. Manufacturability

A delicate or loosely woven textile might have a beautiful and unique appearance, but it can be a significant challenge in production. Without the right backing, it may stretch unpredictably or tear during the lasting process, leading to high failure rates on the assembly line.

Making the Right Choice for Your Shoe

Your material selection strategy should always begin with the end-use of the shoe. Define the primary goal, and let that guide your decisions across the five pillars.

- If your primary focus is high-performance athletics: Prioritize lightweight synthetic fibers, open-weave or knit patterns for breathability, and specific performance treatments like DWR.

- If your primary focus is rugged outdoor use: Select high-denier synthetic fibers like nylon, tight weave patterns for extreme abrasion resistance, and robust waterproof treatments.

- If your primary focus is everyday casual wear: Balance aesthetics and comfort with durability by choosing versatile fiber blends (e.g., cotton/polyester) with a stable weave and a functional backing.

By systematically evaluating these factors, you move from simply choosing a fabric to engineering footwear with intention and precision.

Summary Table:

| Factor | Key Question | Impact on Shoe |

|---|---|---|

| Fiber Composition | Natural or synthetic? | Durability, moisture-wicking, comfort |

| Thread Size (Denier) | High or low thickness? | Abrasion resistance, weight, flexibility |

| Weave Pattern | Tight or open structure? | Breathability, stretch, tear strength |

| Backing Material | Is reinforcement needed? | Structure, manufacturing stability |

| Surface Treatments | What special properties? | Water resistance, UV protection, odor control |

Ready to engineer the perfect shoe?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material science and production capabilities encompassing all types of shoes and boots ensures your designs are not only visionary but also manufacturable at scale.

Let's discuss your specific needs and turn your concept into a high-quality, market-ready product.

Contact our expert team today to get started

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Breathable Athletic Sneakers - Custom Lightweight Cushioned Footwear Manufacturer

People Also Ask

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What features should warehouse workers look for in work boots? Prioritize Safety, Slip Resistance & All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the common types of safety boots and their primary uses? A Guide to Industrial Footwear