When selecting protective footwear, the choice between modern PVC and traditional leather comes down to the specific demands of your environment. PVC (Polyvinyl Chloride) boots offer a distinct set of advantages, primarily centered on absolute protection from liquids and chemicals, lightweight construction, and ease of maintenance.

The decision is not about which material is universally superior, but which is precisely suited for the task at hand. PVC excels in providing an impermeable barrier for wet or hazardous environments, while leather offers unparalleled long-term durability and comfort for extended daily wear.

The Core Advantages of PVC Footwear

PVC boots are engineered from a synthetic plastic polymer, giving them inherent properties that are ideal for specific applications. Their single-piece, molded construction is key to their primary benefits.

An Absolute Liquid and Chemical Barrier

Because PVC is non-porous, these boots are completely waterproof right out of the box. There are no seams to fail or materials to saturate.

This material is also highly resistant to a wide range of chemicals, including acids, alkalis, and oils, making it a default choice in industrial, agricultural, and sanitation settings.

Lightweight and Easy to Wear

PVC boots are significantly lighter than most leather work boots, reducing leg fatigue over a work shift.

Their typical slip-on, tall-shaft design makes them incredibly easy to put on and take off, which is a practical benefit for tasks requiring frequent changes in footwear or for decontamination purposes.

Simple Maintenance and Hygiene

Cleaning PVC is straightforward. The smooth, non-absorbent surface can be quickly hosed down and sanitized without damaging the material. This is a critical feature in food processing or hazardous material handling.

The Enduring Case for Leather

Full-grain leather has been the standard for durable footwear for centuries for good reason. It offers a different kind of performance centered on longevity and wearer comfort.

Unmatched Durability and Longevity

High-quality leather boots are known for their exceptional abrasion resistance and strength. With proper care, they can provide multiple seasons of reliable service.

Leather also molds to the wearer's foot over time, creating a custom fit that can't be replicated by synthetic materials.

Repairability and Long-Term Value

A key advantage of many premium leather boots is their construction, which often allows them to be resoled by a cobbler.

This ability to replace a worn-out sole dramatically extends the life of the boot, turning an initial purchase into a long-term investment.

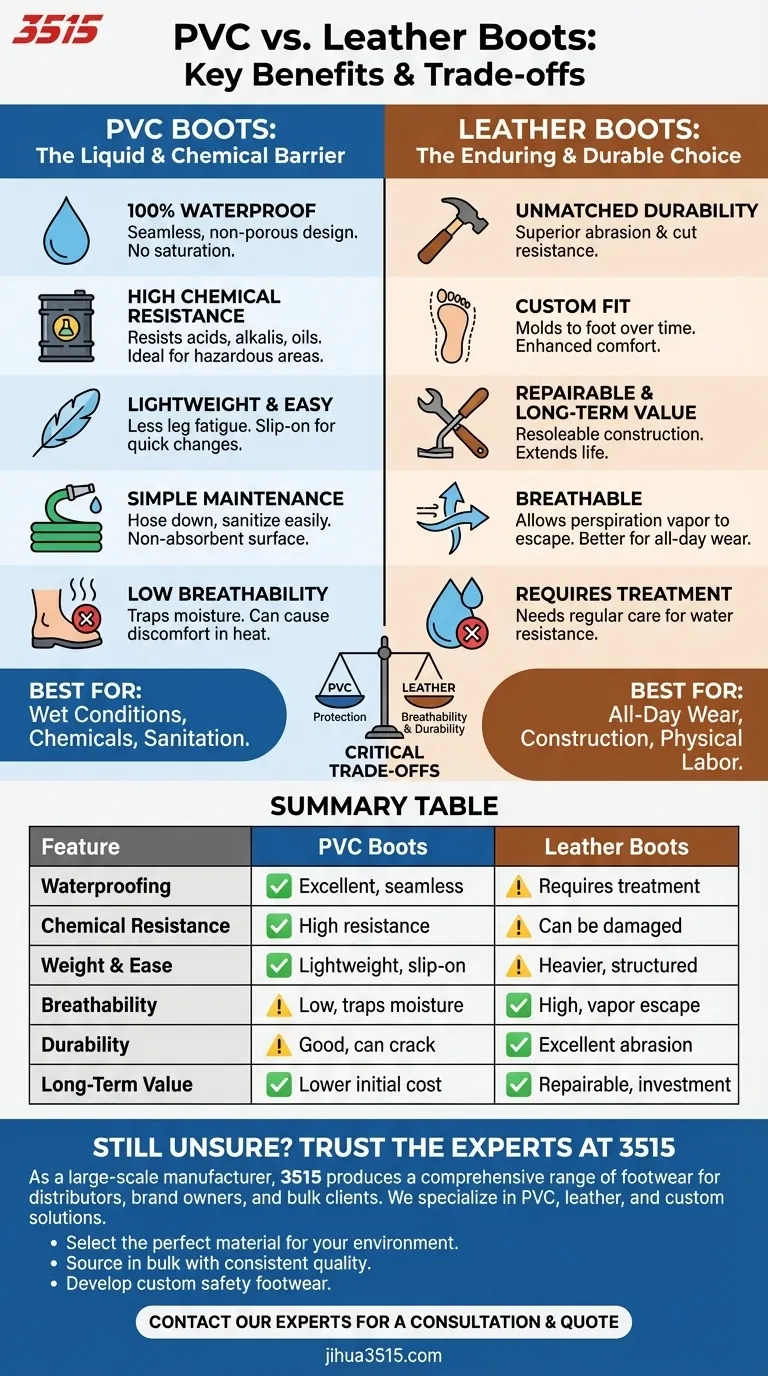

Understanding the Critical Trade-offs

Choosing the right boot requires an objective look at where each material excels and where it falls short. The best choice is always a compromise based on your primary need.

Protection vs. Breathability

PVC provides a perfect seal against external moisture, but it also traps all internal moisture. In warm conditions or during strenuous activity, this lack of breathability can lead to significant discomfort from sweat.

Leather, on the other hand, is a naturally breathable material. While it requires treatments to remain water-resistant, it allows perspiration vapor to escape, which is crucial for all-day foot health and comfort.

Chemical Resistance vs. Abrasion Resistance

PVC is the clear winner for direct chemical exposure, but it can be more susceptible to cuts, punctures, and cracking from repeated flexing, especially in cold temperatures.

Leather offers superior resistance to cuts and abrasion found in construction or rough terrain. However, harsh chemicals can permanently damage and weaken the leather itself.

Making the Right Choice for Your Task

Your optimal choice depends entirely on the demands of your environment and the duration of wear.

- If your primary focus is handling chemicals, sanitation, or working in extremely wet conditions: Choose PVC for its absolute waterproof and chemical-resistant barrier.

- If your primary focus is all-day wear, construction, or demanding physical labor: Choose leather for its superior long-term durability, breathability, and comfort.

Selecting the right material is the foundation for ensuring your safety, comfort, and performance on the job.

Summary Table:

| Feature | PVC Boots | Leather Boots |

|---|---|---|

| Waterproofing | Excellent, seamless barrier | Requires treatment, can saturate |

| Chemical Resistance | High resistance to acids/oils | Can be damaged by chemicals |

| Weight & Ease | Lightweight, easy slip-on | Heavier, more structured |

| Breathability | Low, traps moisture | High, allows vapor escape |

| Durability | Good, but can crack in cold | Excellent abrasion resistance |

| Long-Term Value | Lower initial cost | Repairable, long-term investment |

Still Unsure Which Boot is Right for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized PVC and durable leather work boots.

We can help you:

- Select the perfect material based on your specific work environment—chemical, wet, or rugged terrain.

- Source in bulk with consistent quality and competitive pricing.

- Develop custom footwear tailored to your unique safety and comfort requirements.

Get the right footwear for the job. Contact our experts today for a personalized consultation and quote!

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Are military camouflage boots waterproof? How to Choose Boots That Keep Feet Dry

- Why is waterproofing important in tactical boots? Essential for Foot Health & Mission Success

- What are tactical operations and what do they encompass? Master the Principles for Mission Success

- How do military camouflage boots protect against adverse weather? Ensuring Dry, Warm Feet in Any Condition

- What was the primary motivation for developing this new jungle boot? Solving Critical Failures in Tropical Warfare