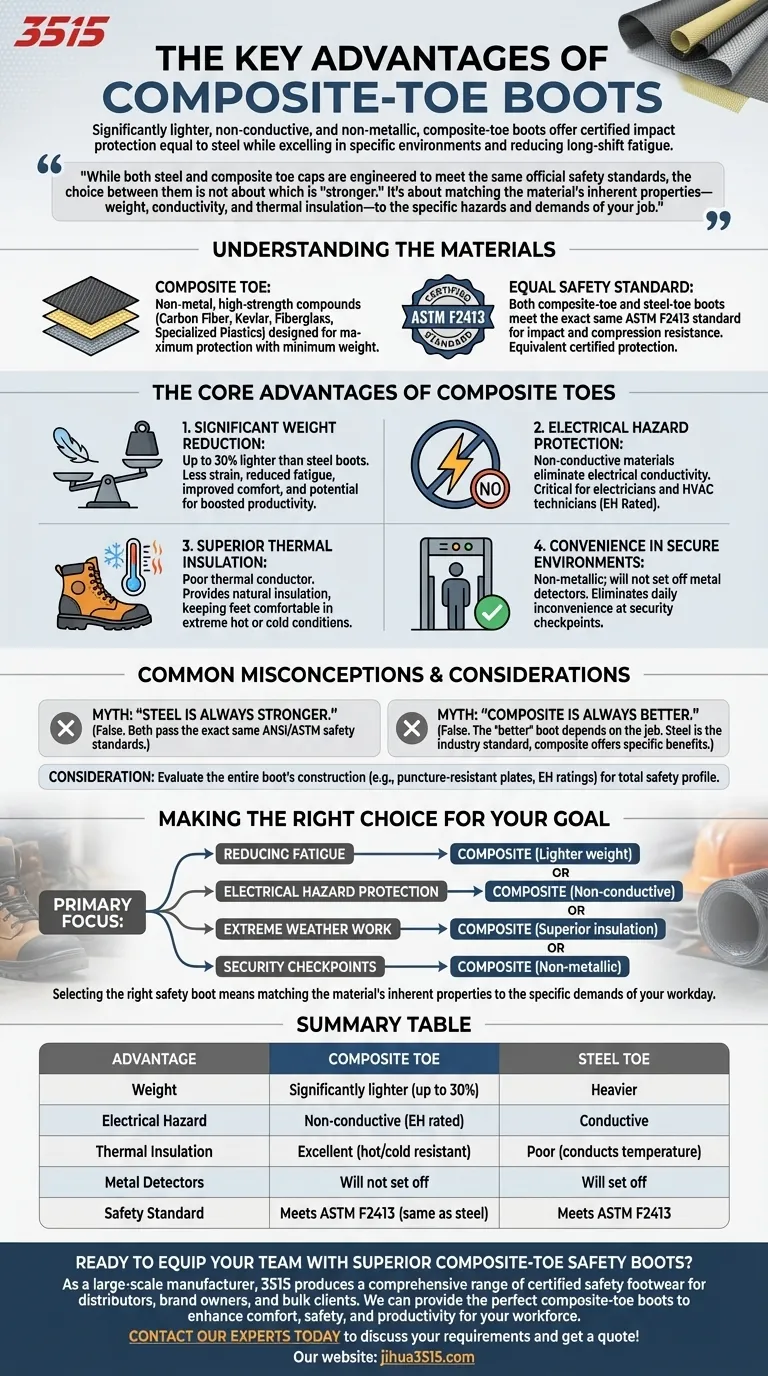

The key advantages of composite-toe boots are their significantly lighter weight, their inability to conduct electricity or temperature, and their non-metallic nature. While offering the same certified impact protection as steel toes, these material properties make them superior for specific environments and for reducing user fatigue over long shifts.

While both steel and composite toe caps are engineered to meet the same official safety standards, the choice between them is not about which is "stronger." It's about matching the material's inherent properties—weight, conductivity, and thermal insulation—to the specific hazards and demands of your job.

Understanding the Materials

What "Composite Toe" Means

A composite toe cap is built from non-metal materials. These are advanced, high-strength compounds designed for maximum protection with minimum weight.

Common materials include carbon fiber, Kevlar, fiberglass, and specialized plastics. The goal is to create a safety toe that is strong enough to pass rigorous testing but avoids the drawbacks of metal.

The Standard for Safety is Equal

Both composite-toe and steel-toe boots sold for safety purposes must meet the same ASTM F2413 standard for impact and compression resistance.

This means that for the certified level of protection, a composite toe is designed to withstand the same forces as a steel toe. One is not inherently "weaker" than the other in the eyes of safety certification.

The Core Advantages of Composite Toes

Advantage #1: Significant Weight Reduction

Composite materials are substantially lighter than steel, with some boots being up to 30% lighter overall.

This weight reduction directly translates to less strain on your legs and feet. Over a long workday, this can significantly reduce fatigue and improve comfort, potentially boosting overall productivity.

Advantage #2: Electrical Hazard Protection

Because they are made from non-metallic materials, composite toes do not conduct electricity.

This is a critical safety feature for anyone working with or around live circuits, such as electricians or HVAC technicians. Boots with this feature often carry an Electrical Hazard (EH) rating.

Advantage #3: Superior Thermal Insulation

Steel is an excellent conductor of temperature, meaning steel-toe boots can become uncomfortably cold in winter and hot in summer.

Composite materials are poor thermal conductors. This provides natural insulation, keeping your feet more comfortable in extreme hot or cold working conditions.

Advantage #4: Convenience in Secure Environments

The non-metallic nature of composite toes means they will not set off metal detectors.

This is a major practical advantage for professionals who must frequently pass through security checkpoints, eliminating a daily inconvenience.

Common Misconceptions and Considerations

Myth: "Steel is always stronger."

For the threats that safety footwear is certified to protect against, this is false. Both steel and composite toes must pass the exact same ANSI/ASTM impact and compression standards to be sold as protective footwear. The certified protection level is equivalent.

Myth: "Composite is always better."

The "better" boot is entirely dependent on the job. While composite offers clear advantages in weight and conductivity, steel has been the industry standard for decades due to its proven track record and slightly lower profile in some designs.

Consideration: Overall Boot Construction

The toe cap is only one part of the boot's protection. Features like puncture-resistant plates in the sole or specific EH ratings are separate considerations that define the boot's total safety profile. Always evaluate the entire boot's specifications, not just the toe material.

Making the Right Choice for Your Goal

The best boot is the one that addresses your primary daily challenges. Use your main priority to guide your decision.

- If your primary focus is reducing fatigue: Composite is the clear winner due to its lighter weight, which makes a noticeable difference over a long shift.

- If your primary focus is protection from electrical hazards: Composite is the essential and non-negotiable choice for its non-conductive properties.

- If your primary focus is working in extreme hot or cold weather: Composite provides superior thermal insulation for greater all-day comfort.

- If your primary focus is convenience at security checkpoints: Composite allows you to pass through metal detectors without issue.

Ultimately, selecting the right safety boot means matching the material's inherent properties to the specific demands of your workday.

Summary Table:

| Advantage | Composite Toe | Steel Toe |

|---|---|---|

| Weight | Significantly lighter (up to 30%) | Heavier |

| Electrical Hazard | Non-conductive (EH rated) | Conductive |

| Thermal Insulation | Excellent (hot/cold resistant) | Poor (conducts temperature) |

| Metal Detectors | Will not set off | Will set off |

| Safety Standard | Meets ASTM F2413 (same as steel) | Meets ASTM F2413 |

Ready to equip your team with superior composite-toe safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We can provide the perfect composite-toe boots to enhance comfort, safety, and productivity for your workforce.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime