At its core, tactical boot midsole technology centers on three critical functions: shock absorption, structural support, and managing stiffness. This is achieved through carefully selected materials like EVA and PU foam, and integrated components like shanks and contoured footbeds, which work together to protect your joints, reduce fatigue, and provide stability across varied terrain.

The midsole is the most critical component for a boot's performance and your long-term health. It's not just a layer of cushioning; it is an engineered system designed to balance the competing demands of comfort, stability, and durability for mission-specific needs.

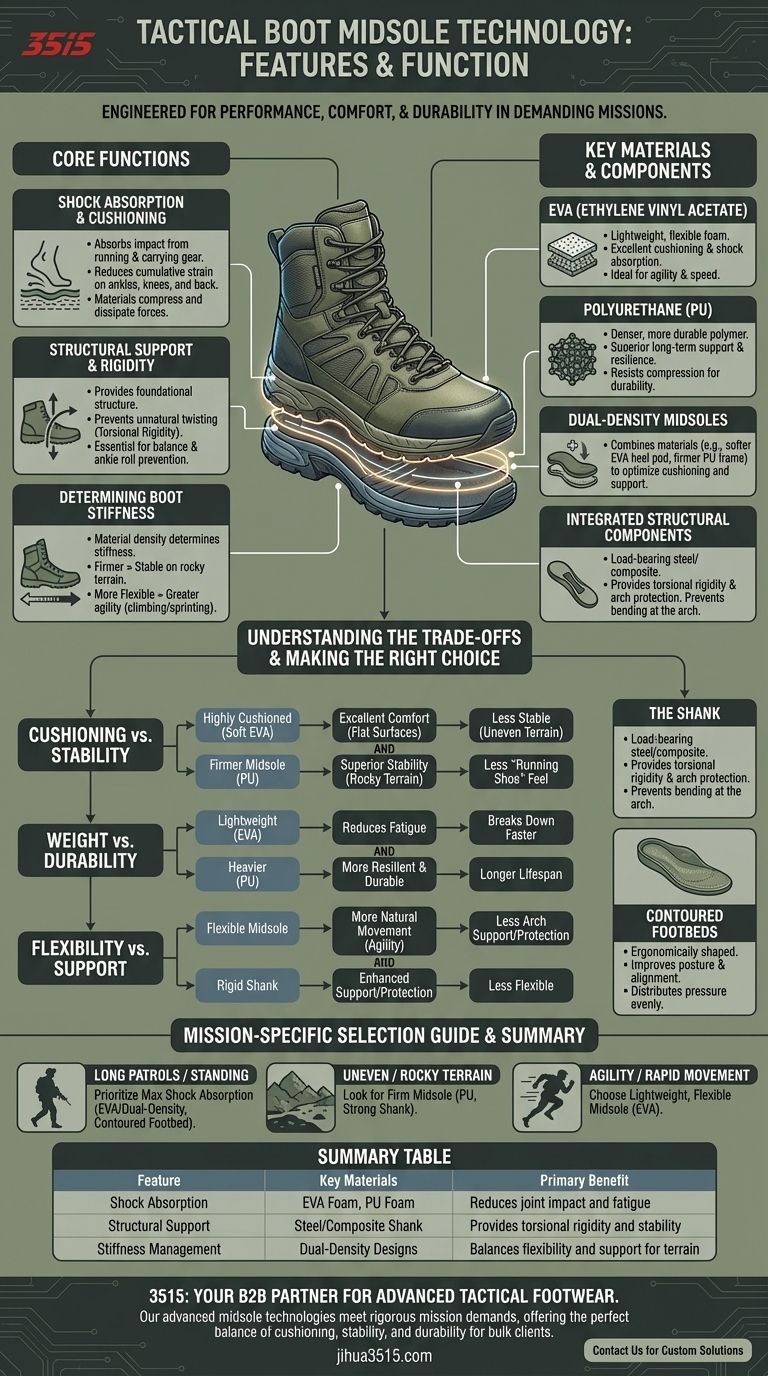

The Core Functions of a Tactical Midsole

A tactical boot's midsole serves as the primary interface between your foot and the ground. Its design directly dictates how the boot feels and performs under stress, going far beyond simple comfort.

Shock Absorption and Cushioning

The most fundamental job of the midsole is to absorb impact. Every step, especially when running or carrying gear, sends shockwaves up through your ankles, knees, and back.

Materials like EVA and PU are engineered to compress and dissipate these forces, significantly reducing the cumulative strain on your body over a long day.

Structural Support and Rigidity

A midsole provides the foundational structure of the boot. It incorporates components that prevent the boot from twisting unnaturally on uneven ground, a property known as torsional rigidity.

This structural integrity is essential for maintaining balance and preventing ankle rolls, particularly when navigating challenging terrain or carrying a heavy load.

Determining Boot Stiffness

The material density and design of the midsole determine the boot's overall stiffness. A firmer midsole offers greater stability on rocky or unpredictable surfaces, acting as a stable platform that reduces foot strain.

Conversely, a more flexible midsole allows for a greater range of motion, which is ideal for activities requiring agility like climbing or sprinting.

Key Materials and Their Impact

The choice of material is the primary factor influencing a midsole's characteristics. Each material offers a distinct blend of weight, durability, and cushioning.

EVA (Ethylene Vinyl Acetate)

EVA is a lightweight, flexible foam that provides excellent cushioning and shock absorption. It's the same material found in most high-performance running shoes.

This makes it ideal for boots where agility, speed, and immediate comfort are the top priorities.

Polyurethane (PU)

PU is a denser and more durable polymer than EVA. While slightly heavier, it offers superior long-term support and resilience, resisting compression far longer.

Boots with PU midsoles are built for durability and are an excellent choice for users who need consistent support over thousands of miles.

Dual-Density Midsoles

Advanced designs often combine materials to optimize performance. A dual-density midsole might use a softer EVA pod in the heel for maximum impact absorption and a firmer PU frame for stability and durability.

This approach allows manufacturers to fine-tune the boot's performance without making a direct trade-off between cushioning and support.

Integrated Structural Components

Beyond foam, midsoles incorporate rigid elements that are critical for protection and ergonomic support.

The Shank

The shank is a load-bearing piece of steel or composite material embedded within the midsole, running from the heel to the ball of the foot.

Its primary purpose is to provide torsional rigidity and protect the foot's arch. This "spine" is what prevents the boot from bending at the arch, ensuring your foot is supported correctly.

Contoured Footbeds

Many tactical boots feature midsoles that are ergonomically shaped to follow the natural contours of the human foot.

This design improves posture and alignment, distributing pressure more evenly and reducing specific points of fatigue during long periods of standing or walking.

Understanding the Trade-offs

There is no single "best" midsole technology; there is only the best for a specific application. Understanding the inherent trade-offs is key to making an informed choice.

Cushioning vs. Stability

A highly cushioned, soft EVA midsole provides excellent comfort on flat, hard surfaces. However, that same softness can feel unstable and reduce feedback from the ground on rocky or uneven terrain. A firmer PU midsole offers superior stability at the cost of that "running shoe" feel.

Weight vs. Durability

Lightweight EVA is a clear winner for reducing fatigue on the move, but it will break down and lose its cushioning properties faster than the heavier but more resilient PU. Your expected intensity and duration of use should guide this choice.

Flexibility vs. Support

A flexible midsole without a rigid shank allows for more natural foot movement, which is beneficial for agility. However, this comes at the expense of arch support and protection, making it less suitable for carrying heavy loads or navigating hazardous environments.

Making the Right Choice for Your Mission

Your choice of midsole technology should be directly informed by your primary operational environment and physical demands.

- If your primary focus is long patrols or standing for hours: Prioritize maximum shock absorption with a high-quality EVA or dual-density midsole and a contoured footbed.

- If your primary focus is stability on uneven or rocky terrain: Look for a boot with a firm PU midsole and a strong, integrated composite or steel shank.

- If your primary focus is agility and rapid movement: Choose a boot with a lightweight, flexible EVA midsole that allows for a greater range of motion.

Understanding your boot's midsole transforms it from simple footwear into a critical tool for performance and endurance.

Summary Table:

| Midsole Feature | Key Materials/Components | Primary Benefit |

|---|---|---|

| Shock Absorption | EVA Foam, PU Foam | Reduces joint impact and fatigue |

| Structural Support | Steel/Composite Shank | Provides torsional rigidity and stability |

| Stiffness Management | Dual-Density Designs | Balances flexibility and support for terrain |

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical footwear for distributors, brand owners, and bulk clients. Our advanced midsole technology—including EVA, PU, and dual-density designs with integrated shanks—is engineered to meet the rigorous demands of your mission. Whether you need boots optimized for long patrols, rocky terrain, or rapid movement, our production capabilities deliver the perfect balance of cushioning, stability, and durability. Contact us today to discuss custom solutions for your tactical footwear needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- Why are tactical work boots ideal for law enforcement? Boost Performance & Safety

- How often should full grain leather tactical boots be conditioned? A Guide to Maximize Boot Lifespan

- What is the function of biosynthetic protein fibers in the production of smart fabrics for tactical boots?

- What are the characteristics of motorcycle combat boots? Style vs. Safety Explained

- Why is standard footwear chosen as the integration platform for smart wearable metal detection? Boost Tactical Mobility

- What are the key aspects of sole construction in tactical boots? Master the Foundation for Performance

- What role does the midsole play in tactical boots? Unlock Core Performance & Protection

- What are the requirements for military personnel when selecting tactical boots? A Guide to Compliance & Performance