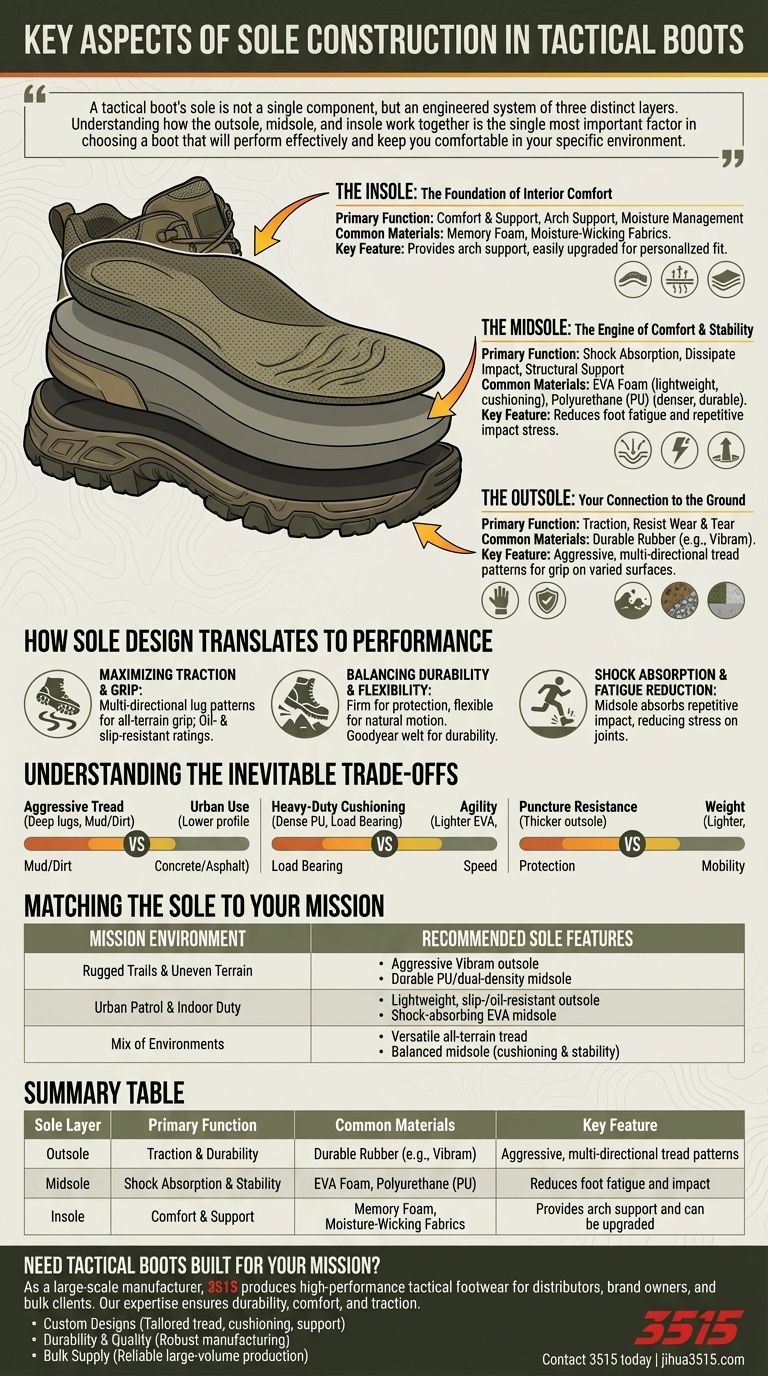

The key aspects of tactical boot sole construction involve a three-part system: the outsole for traction, the midsole for shock absorption, and the insole for comfort. The outsole is typically made of durable rubber with aggressive, multi-directional tread patterns for grip on varied surfaces, while the midsole uses materials like EVA foam or polyurethane to reduce foot fatigue. The insole provides direct underfoot comfort and support.

A tactical boot's sole is not a single component, but an engineered system of three distinct layers. Understanding how the outsole, midsole, and insole work together is the single most important factor in choosing a boot that will perform effectively and keep you comfortable in your specific environment.

Deconstructing the Tactical Boot Sole: A Three-Layer System

To truly understand a tactical boot, you must look at its foundation. The sole is comprised of three critical layers, each with a specialized role in performance, protection, and comfort.

The Outsole: Your Connection to the Ground

The outsole is the bottom-most layer that makes direct contact with the terrain. Its primary jobs are to provide traction and resist wear and tear.

Outsoles are almost always made of durable rubber compounds. High-performance brands like Vibram are often used for their superior grip and longevity in rugged conditions. The tread pattern is also crucial; deep, aggressive lugs excel at gripping soft ground like mud and gravel, while broader patterns provide more surface contact for stability on hard, flat surfaces.

The Midsole: The Engine of Comfort and Stability

Sandwiched between the outsole and your foot, the midsole is the boot's suspension system. Its main purpose is to absorb shock, dissipate impact, and provide structural support to reduce foot fatigue.

Common midsole materials include EVA (ethylene vinyl acetate) foam, which is lightweight and offers excellent cushioning, and Polyurethane (PU), which is denser, heavier, and more durable. Many boots use a combination of these materials to balance cushioning with long-term support.

The Insole: The Foundation of Interior Comfort

The insole, or footbed, is the removable layer inside the boot that your foot rests on directly. It provides the final layer of cushioning and is critical for arch support and moisture management.

Quality insoles may feature memory foam for customized padding, moisture-wicking top layers to keep feet dry, and antimicrobial treatments to prevent odor. This is often the easiest component of a boot to upgrade for a more personalized fit.

How Sole Design Translates to Performance

The materials and design of each sole layer directly impact how the boot feels and performs during use. The right combination can make the difference between agility and fatigue.

Maximizing Traction and Grip

A boot's ability to prevent slips and falls is determined by its outsole. Multi-directional lug patterns ensure reliable grip whether you are moving uphill, downhill, or laterally. For industrial or urban settings, look for outsoles specifically rated as oil- and slip-resistant.

Balancing Durability and Flexibility

A boot's sole must be firm enough to protect your foot from sharp objects and rough terrain, yet flexible enough to allow for a natural range of motion. The overall construction method, such as a Goodyear welt or stitch-down construction, also signals a durable, often repairable, build quality.

Shock Absorption and Fatigue Reduction

The midsole is the unsung hero of all-day comfort. By absorbing the repetitive impact of walking or running, a well-designed midsole significantly reduces the stress on your feet, knees, and back, preventing fatigue over long periods.

Understanding the Inevitable Trade-offs

There is no single "best" sole design; every choice is a trade-off. Recognizing this is key to selecting the right boot for your needs.

Aggressive Tread vs. Urban Use

Deep, widely-spaced lugs are ideal for mud and loose dirt but can feel unstable and wear down quickly on concrete or asphalt. Boots designed for urban environments will have a lower-profile tread for better surface contact and quieter movement.

Heavy-Duty Cushioning vs. Agility

A thick, dense PU midsole offers maximum support and durability, making it perfect for carrying heavy loads. However, this adds weight and can make the boot feel less responsive than one with a lighter EVA midsole, which prioritizes speed and agility.

Puncture Resistance vs. Weight

A thicker, harder outsole provides superior protection against punctures from nails or sharp rocks. This robustness, however, comes at the cost of increased weight and reduced flexibility, which can impact overall mobility and comfort.

Matching the Sole to Your Mission

Your choice should be dictated entirely by your primary operational environment and physical demands.

- If your primary focus is rugged trails and uneven terrain: Prioritize a boot with an aggressive, deep-lugged Vibram or similar outsole and a supportive, durable PU or dual-density midsole.

- If your primary focus is urban patrol or indoor duty: Look for a lightweight boot with a slip- and oil-resistant outsole with a moderate tread, paired with a shock-absorbing EVA midsole for all-day comfort.

- If your primary focus is a mix of environments: Seek a versatile all-terrain design with multi-directional lugs and a balanced midsole that offers both cushioning and stability.

Ultimately, choosing the right boot means selecting the right foundation for your feet, ensuring your gear enhances your performance instead of holding you back.

Summary Table:

| Sole Layer | Primary Function | Common Materials | Key Feature |

|---|---|---|---|

| Outsole | Traction & Durability | Durable Rubber (e.g., Vibram) | Aggressive, multi-directional tread patterns |

| Midsole | Shock Absorption & Stability | EVA Foam, Polyurethane (PU) | Reduces foot fatigue and impact |

| Insole | Comfort & Support | Memory Foam, Moisture-Wicking Fabrics | Provides arch support and can be upgraded |

Need Tactical Boots Built for Your Mission?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance tactical footwear for distributors, brand owners, and bulk clients. Our expertise in sole construction ensures your team gets the perfect balance of durability, comfort, and traction for any environment.

We can help you with:

- Custom Designs: Tailor the outsole tread, midsole cushioning, and insole support to your specific operational needs.

- Durability & Quality: Benefit from our robust manufacturing capabilities for boots that last.

- Bulk Supply: Reliable, large-volume production to meet your demand.

Let's build the foundation for your team's success. Contact 3515 today to discuss your tactical boot requirements!

Visual Guide

Related Products

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

People Also Ask

- What is the correct way to store tactical boots when not in use? Extend Their Lifespan with Expert Tips

- What are the characteristics of motorcycle combat boots? Style vs. Safety Explained

- How do tactical boots and regular shoes differ in cushioning and padding? Unlock the Key to Performance & Protection

- What are the advantages and disadvantages of waterproof tactical boots? A Guide to the Key Trade-Offs

- Are tactical boots suitable for hiking? Discover the Ultimate Footwear for Rugged Trails

- Why is water resistance an important feature in tactical boots? Ensuring Operational Readiness and Foot Health

- What is the importance of taking care of tactical boots? Maximize Lifespan, Safety & Performance

- Why are professional tactical boots essential for traffic environments? Protect Long-Term Health & Mobility