The primary durability requirement for a walking shoe is a sturdy, well-constructed rubber outsole capable of withstanding prolonged contact with various surfaces. While the outsole is the most critical component for wear resistance, the upper materials and midsole construction also play a significant role in the shoe's overall lifespan and ability to provide consistent support.

True durability in a walking shoe is not about a single feature, but a balanced system. It’s the result of a high-quality rubber outsole working in tandem with a resilient upper and a compression-resistant midsole to endure daily stress without sacrificing essential comfort and flexibility.

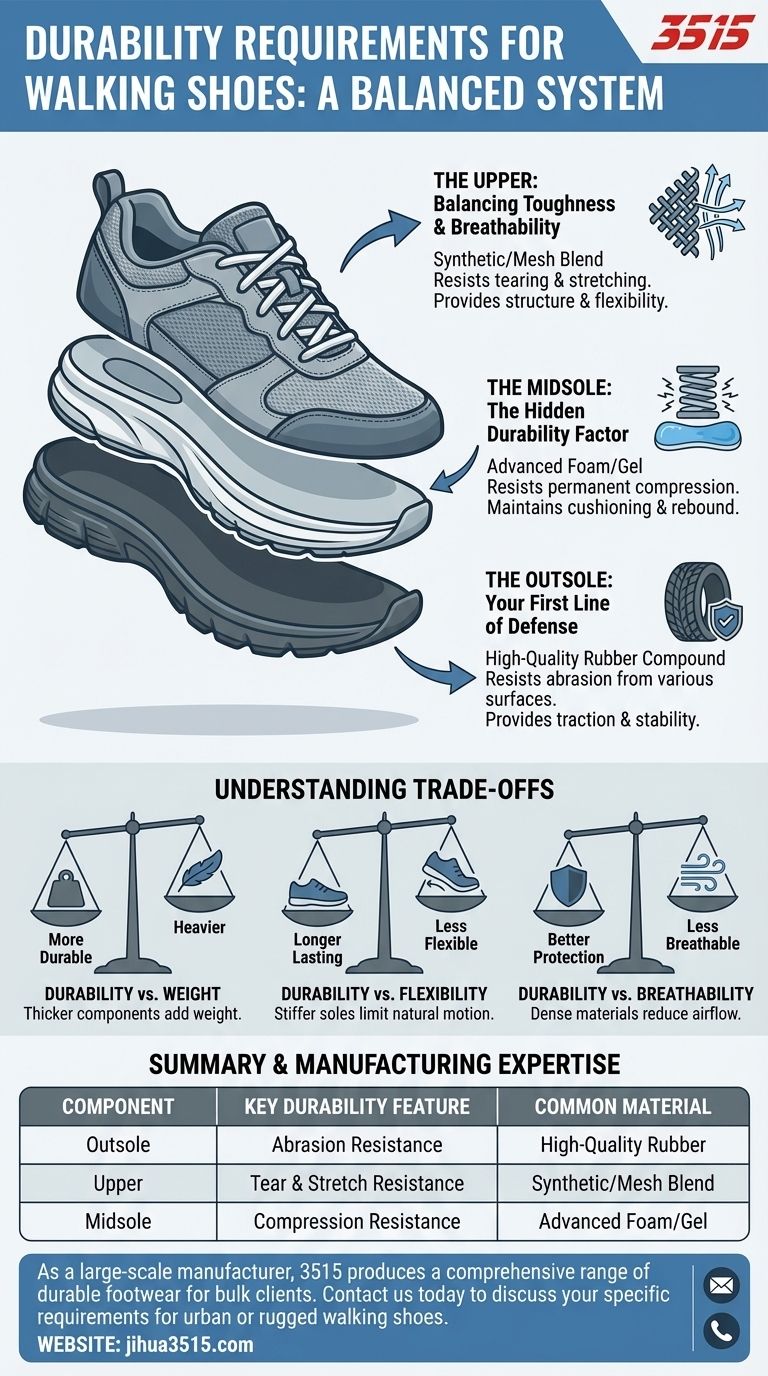

Deconstructing Walking Shoe Durability

To properly assess a shoe's durability, you must understand how its core components contribute to its longevity. A shoe is only as strong as its weakest part.

The Outsole: Your First Line of Defense

The outsole is the part of the shoe that makes direct contact with the ground and, as a result, endures the most abrasion and impact.

A truly durable outsole is made from a high-quality, sturdy rubber compound. This material is engineered to resist being worn down by pavement, trails, and other surfaces while providing necessary traction and stability.

The Upper: Balancing Toughness and Breathability

The upper is everything above the sole. Its durability is determined by its resistance to stretching, tearing, and fraying from flexing and external scuffs.

Most quality walking shoes use a combination of synthetic materials and engineered mesh. The synthetics provide structure and abrasion resistance in high-wear areas, while the mesh offers crucial flexibility and breathability.

The Midsole: The Hidden Durability Factor

The midsole provides cushioning and absorbs shock. Its durability isn't about resisting scrapes, but about its ability to resist permanent compression.

A low-quality foam midsole will flatten quickly, losing its cushioning and support long before the outsole wears out. A durable midsole, often made of advanced foams or featuring technologies like gel inserts, maintains its structure and rebound for hundreds of miles.

Understanding the Trade-offs

Choosing a walking shoe always involves balancing competing needs. Maximizing durability often requires a compromise in other areas.

Durability vs. Weight

Thicker rubber outsoles and reinforced uppers add significant durability, but they also add weight. The most durable shoes are rarely the lightest. For daily walking, a balance is key, as excessively heavy shoes can lead to fatigue.

Durability vs. Flexibility

A very hard, thick rubber outsole will last for a very long time, but it may be too stiff to allow for a natural and comfortable walking motion. A good walking shoe must be flexible enough to bend with your foot, particularly at the forefoot.

Durability vs. Breathability

Highly durable upper materials, like dense synthetics or leather, offer excellent protection against wear and tear. However, they often sacrifice breathability, which can lead to discomfort in warmer conditions. Mesh panels are a common solution to this trade-off.

Making the Right Choice for Your Needs

Focus on the components that matter most for how you plan to use the shoes. A visual inspection of the outsole thickness and the quality of the upper stitching can tell you a lot.

- If your primary focus is longevity for daily urban walking: Prioritize a shoe with a solid, high-quality rubber outsole and a well-stitched synthetic and mesh upper.

- If you walk frequently on varied or rough terrain: Look for a thicker, more aggressive outsole with deeper lugs for better traction and wear resistance.

- If your primary focus is lightweight comfort for travel or casual wear: You may opt for a shoe with a slightly thinner outsole and a more flexible, mesh-dominant upper, accepting a modest trade-off in maximum lifespan.

By understanding these key components and their inherent trade-offs, you can confidently select a walking shoe that is truly built to last.

Summary Table:

| Component | Key Durability Feature | Common Material |

|---|---|---|

| Outsole | Abrasion Resistance | High-Quality Rubber |

| Upper | Tear & Stretch Resistance | Synthetic/Mesh Blend |

| Midsole | Compression Resistance | Advanced Foam/Gel |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of walking shoes and boots, engineered with high-quality rubber outsoles, resilient uppers, and compression-resistant midsoles to ensure long-lasting performance. Whether you need urban walking shoes or rugged outdoor boots, we deliver the durability your customers demand. Contact us today to discuss your specific requirements and leverage our manufacturing expertise for your next footwear line!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What should you look for in terms of flexibility in walking shoes? Find the Perfect Fit for Your Stride

- How do horse boots help in injury prevention during training? Shield, Support, and Enhance Coordination

- What are the key components of a walking boot's sole unit? A Guide to Outsole, Midsole, and Insole

- What factors should be considered when choosing walking shoes? Find Your Perfect Fit for Comfort & Support

- What are the pros of the Best Budget walking shoes? Get Superior Comfort & Support Without the High Cost

- Why are socks important for walking footwear? The Key to Blister-Free Comfort

- What are the benefits of comfortable Western riding boots? Enhance Performance & All-Day Comfort

- How do snow boots differ from winter boots in terms of design? A Guide to Choosing the Right Footwear