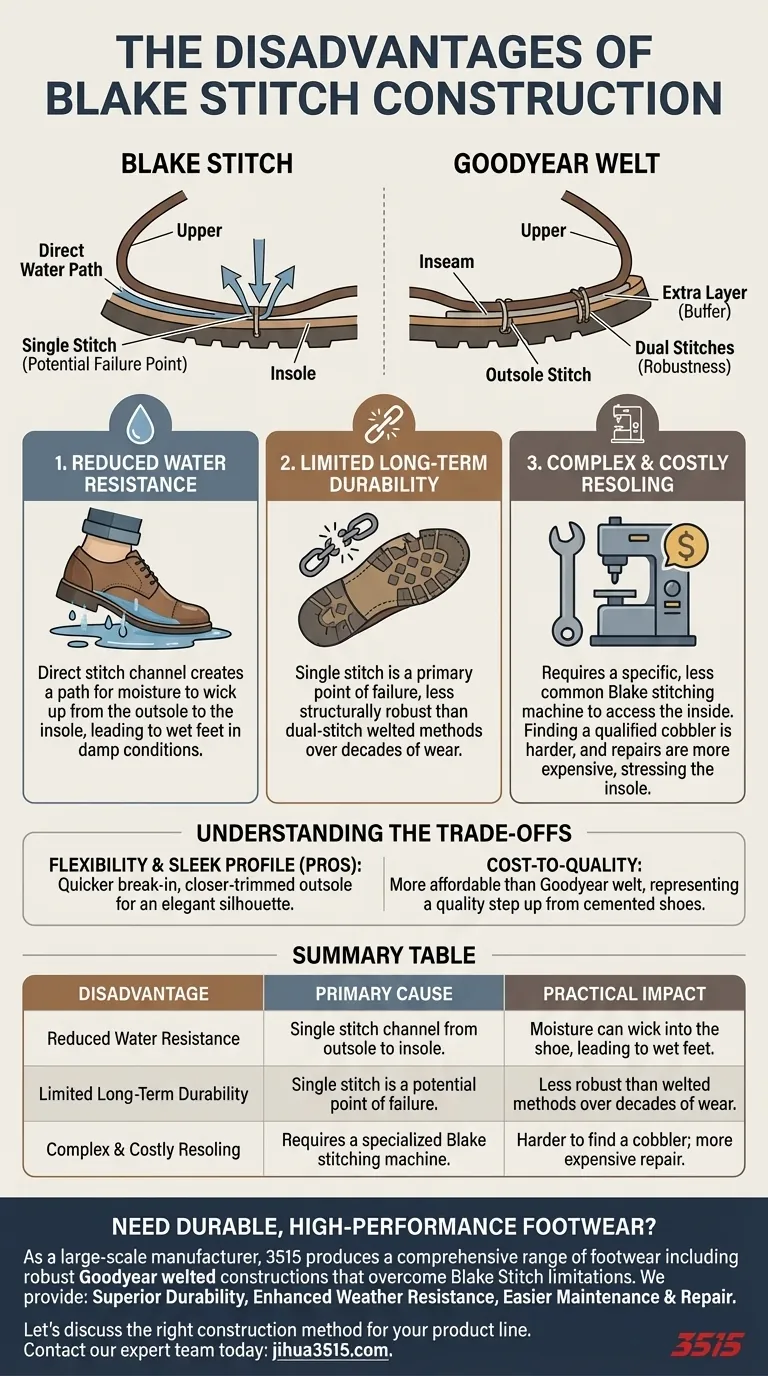

The primary disadvantages of Blake Stitch construction are reduced water resistance, less long-term durability compared to welted methods, and a more complex, machine-dependent resoling process. These drawbacks stem directly from its single-stitch design, which connects the outsole directly to the insole and upper from the inside.

The core issue with Blake Stitch is not that it is a poor construction, but that it prioritizes flexibility and a sleek profile over the absolute water resistance and repairability found in more robust methods like the Goodyear welt.

What is Blake Stitch Construction?

A Direct Connection

Blake Stitching involves a single, continuous stitch that runs from the inside of the shoe, through the insole and the upper, and attaches directly to the outsole.

This creates a very direct and simple connection between the shoe's main components. This method is what gives the final shoe its signature characteristics.

How It Differs

Unlike a cemented (glued) shoe, the stitched connection is far more durable. Unlike a Goodyear welted shoe, there is no extra layer (the "welt") acting as a buffer between the upper and the outsole.

The Primary Disadvantages Explained

Reduced Water Resistance

The stitch channel creates a direct path for water. If you step in a puddle, moisture can wick up through the stitching and into the insole of the shoe, leading to wet feet.

This is the most significant environmental weakness of the Blake Stitch design.

Limited Long-Term Durability

While far more durable than a glued shoe, the single stitch is a potential point of failure. The same internal stitch that holds the shoe together is also exposed to moisture from the inside and abrasion from the outside.

Constructions like a Goodyear welt use two separate stitches, making them structurally more redundant and robust over decades of wear.

Complex and Costly Resoling

To resole a Blake-stitched shoe, a cobbler needs a specific Blake stitching machine to reach inside the shoe and attach the new sole. Not all repair shops have this specialized equipment.

This can make finding a qualified cobbler more difficult and the repair itself more expensive than resoling a Goodyear welted shoe. Furthermore, the process puts stress on the insole, limiting the number of times the shoe can be successfully resoled.

Understanding the Trade-offs

The Benefit of Flexibility

The primary advantage of a Blake Stitch is flexibility. With fewer layers and a direct connection, the sole is far less rigid than a new Goodyear welted shoe, requiring a minimal break-in period.

A Sleeker, Closer-Trimmed Profile

The construction method allows the outsole to be trimmed very close to the upper. This results in a more elegant, streamlined, and less "chunky" silhouette, which is often preferred for dress shoes.

The Cost-to-Quality Equation

Blake Stitch construction is less labor-intensive than Goodyear welting, making the final shoe more affordable. It represents a significant step up in quality and repairability from cemented shoes without the high cost of a top-tier welted shoe.

Making the Right Choice for Your Needs

Choosing the right shoe construction depends entirely on your intended use and priorities.

- If your primary focus is a sleek look and immediate comfort: Blake Stitch is an excellent choice, offering a streamlined profile and flexibility right out of the box.

- If your primary focus is maximum durability and all-weather performance: You should consider a Goodyear welted shoe for its superior water resistance and robust, easily resoleable construction.

- If your primary focus is value for dress or occasional wear: A Blake-stitched shoe offers a durable, high-quality option that is a clear upgrade from lower-end cemented footwear.

Understanding these trade-offs allows you to choose a shoe not just for its style, but for its fundamental engineering.

Summary Table:

| Disadvantage | Primary Cause | Practical Impact |

|---|---|---|

| Reduced Water Resistance | Single stitch channel from outsole to insole. | Moisture can wick into the shoe, leading to wet feet. |

| Limited Long-Term Durability | Single stitch is a potential point of failure. | Less robust than welted methods over decades of wear. |

| Complex & Costly Resoling | Requires a specialized Blake stitching machine. | Harder to find a cobbler; more expensive repair. |

Need Durable, High-Performance Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including robust Goodyear welted constructions that overcome the limitations of Blake Stitch.

We provide:

- Superior Durability: Construction methods built for long-term wear.

- Enhanced Weather Resistance: Designs that protect against the elements.

- Easier Maintenance & Repair: Simplifying the lifecycle for your customers.

Let's discuss the right construction method for your product line.

Contact our expert team today to explore manufacturing solutions tailored to your quality and performance requirements.

Visual Guide

Related Products

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What are the best practices for storing leather work boots? Preserve Your Investment for Years

- What are the advantages of leather uppers in work boots? Unmatched Durability & Protection

- What type of boots are suitable for challenging weather conditions in a business setting? | Durable & Professional Footwear

- What protection do leather work boots need? A Complete Guide to Material Care and Worker Safety

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety