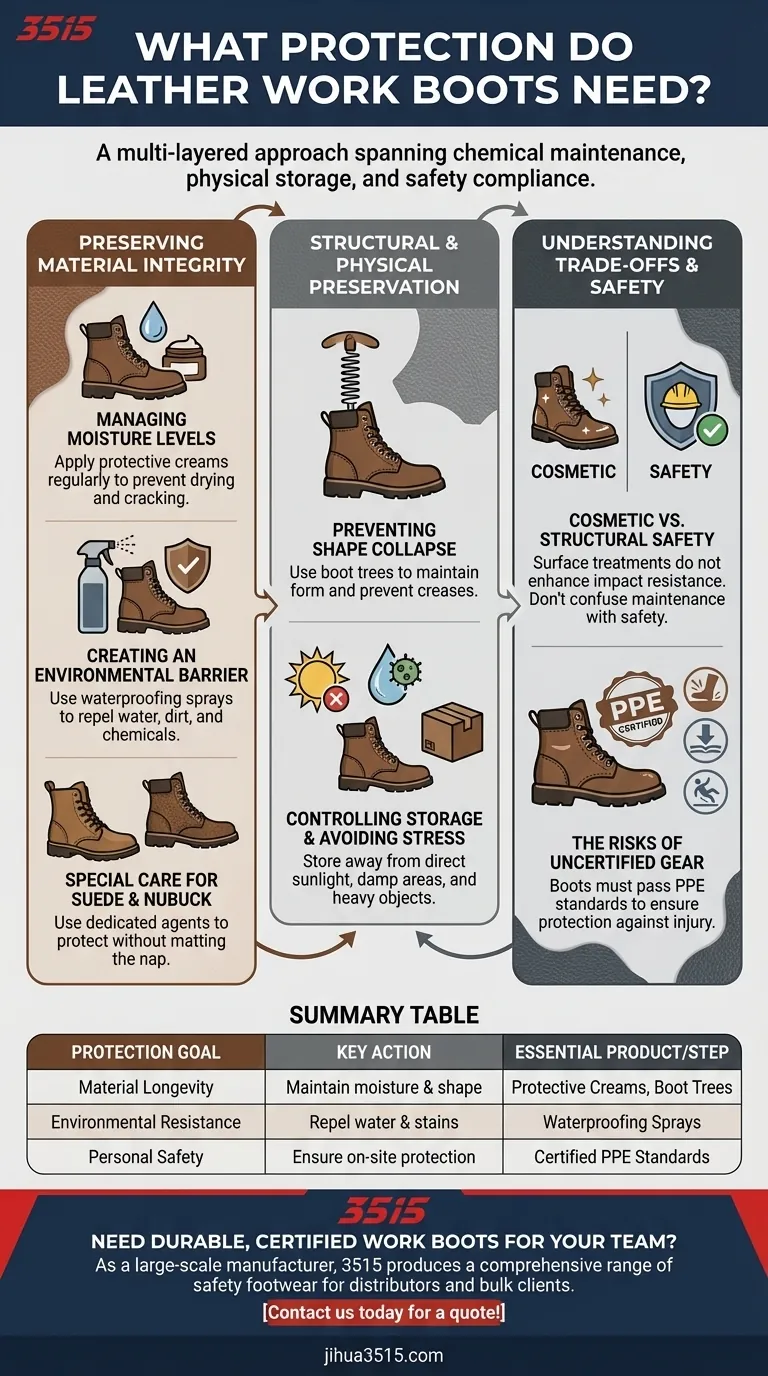

Leather work boots require a multi-layered approach to protection that spans chemical maintenance, physical storage, and safety compliance. To preserve the material, you must use protective creams to maintain moisture and waterproofing sprays to block environmental contaminants. However, true protection also implies ensuring the boot itself is certified to protect the wearer through rigorous PPE standards.

Effective boot protection is a cycle, not a one-time event. It requires balancing chemical treatments to preserve the leather's flexibility with strict adherence to safety certifications and physical care to ensure the boot protects you.

Preserving Material Integrity

Managing Moisture Levels

Leather is a natural material that will deteriorate if allowed to dry out. You must apply protective creams regularly.

These creams maintain the leather's essential moisture balance. Without this maintenance, the material will inevitably become brittle and crack, compromising the boot's longevity.

Creating an Environmental Barrier

External elements like water, mud, and chemicals are the primary enemies of leather. You should utilize waterproofing sprays to create a protective barrier.

This barrier repels water, prevents deep-set stains, and stops dirt from embedding into the fibers.

Special Care for Suede and Nubuck

Not all leathers react the same way to standard treatments. If your boots are made of suede or nubuck, standard creams may ruin the finish.

Instead, use a dedicated waterproofing agent specifically formulated for these textures. This provides necessary protection without matting down the nap of the leather.

Structural and Physical Preservation

Preventing Shape Collapse

Gravity and moisture can cause leather to lose its form over time. It is highly recommended to use boot trees whenever the boots are not in use.

Boot trees apply internal pressure to maintain the correct shape. This prevents the leather from collapsing or developing permanent, damaging creases.

Controlling the Storage Environment

Where you keep your boots is just as important as what you put on them. You must store boots away from direct sunlight, which accelerates fading and drying.

Additionally, avoid damp or humid areas to prevent the growth of mold and mildew.

Avoiding Physical Stress

Leather is durable but pliable. Do not stack heavy objects on top of your work boots during storage.

Heavy loads will crush the upper, causing permanent deformation and potentially compromising the fit.

Understanding the Trade-offs

Cosmetic vs. Structural Safety

It is vital to distinguish between protecting the leather and protecting the worker.

A well-oiled boot looks good, but surface treatments do not enhance impact resistance. Do not confuse material maintenance with safety assurance.

The Risks of Uncertified Gear

A boot that looks protective but lacks certification is a liability. Work boots must pass specific PPE standards to be considered safe.

These certifications verify performance in impact resistance, compression, upper tear strength, and slip resistance. Wearing uncertified boots poses a significant risk of injury or mechanical failure on the job site.

Making the Right Choice for Your Goal

To maximize the life and safety of your work boots, prioritize your actions based on your immediate needs:

- If your primary focus is Material Longevity: Apply protective cream to prevent cracking and use boot trees to stop the leather from collapsing.

- If your primary focus is Environmental Resistance: Utilize waterproofing sprays to shield against water and dirt, switching to specific agents for suede or nubuck.

- If your primary focus is Personal Safety: Ensure your boots carry valid PPE certification for impact, compression, and slip resistance before stepping onto a job site.

Treat your boots as a critical tool, and they will continue to protect you effectively on the job.

Summary Table:

| Protection Goal | Key Action | Essential Product/Step |

|---|---|---|

| Material Longevity | Maintain moisture & shape | Protective Creams, Boot Trees |

| Environmental Resistance | Repel water & stains | Waterproofing Sprays |

| Personal Safety | Ensure on-site protection | Certified PPE Standards |

Need durable, certified work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, ensuring your workforce is protected.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene