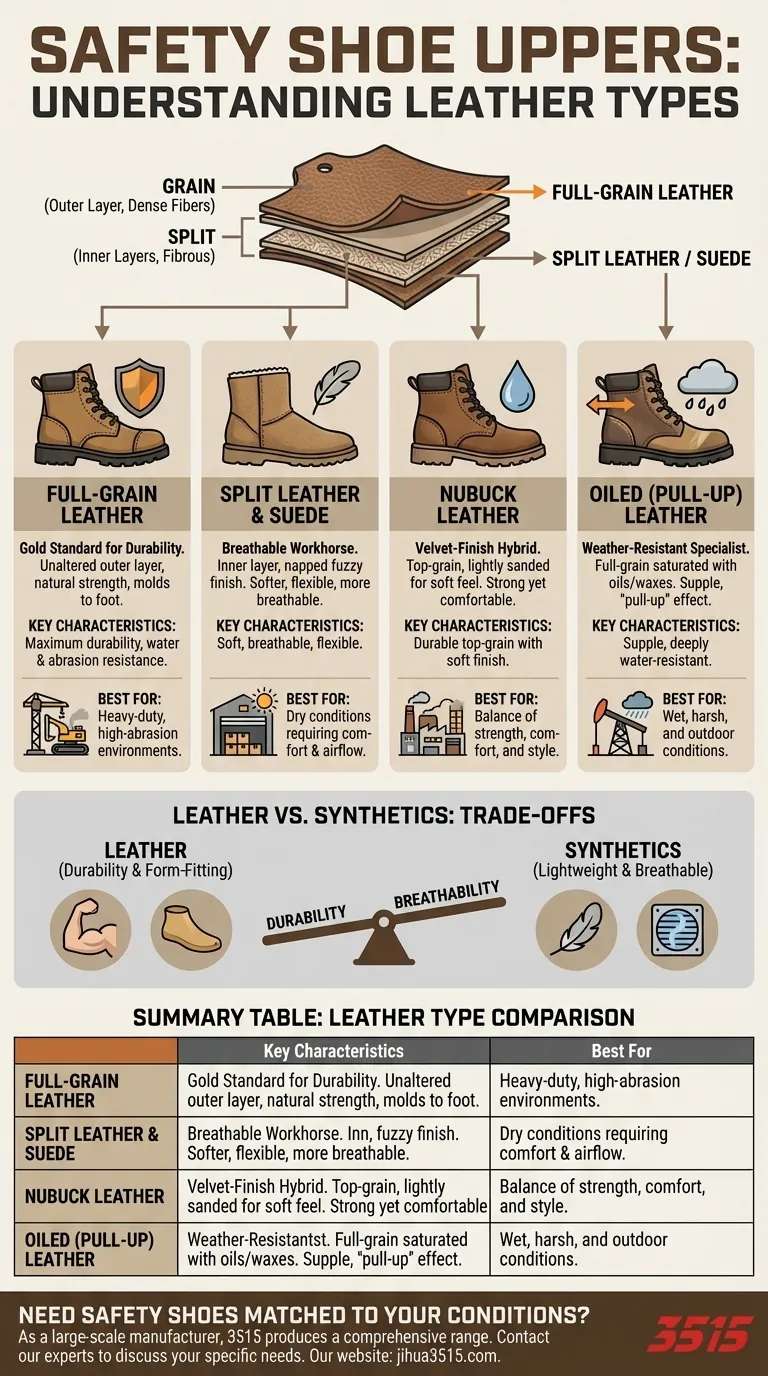

The primary types of leather used for safety shoe uppers are Full-Grain, Split Leather (including Suede), Nubuck, and Oiled Leather. These are not simply different styles but are fundamentally distinct materials derived from various layers of the animal hide. Each is processed uniquely to optimize for specific performance characteristics like durability, breathability, and weather resistance.

The choice of upper material is not about finding the "best" leather, but about matching the material's inherent properties to your specific work environment. Understanding the origin of each leather type is the key to selecting footwear that truly performs.

Understanding the Foundation: The Animal Hide

To choose the right leather, you must first understand where it comes from. The properties of a shoe's upper are determined by which layer of the animal hide is used and how it's treated.

The "Grain" Explained

The "grain" refers to the outermost layer of the hide, the part that faced the elements. It contains the densest and strongest fibers.

Materials that include this top layer, like full-grain leather, are exceptionally durable and resistant to abrasion.

How Splitting Creates Different Leathers

A thick animal hide is often split into two or more layers. The top layer becomes full-grain leather, while the inner, more fibrous layers are known as split leather.

This splitting process is what allows for the creation of different materials, such as suede, from a single hide.

A Breakdown of Common Leather Uppers

Each type of leather offers a different balance of strength, comfort, and resistance.

Full-Grain Leather: The Gold Standard for Durability

This is the highest quality leather, taken from the outer layer of the hide. Its surface is not sanded or buffed, so it retains its natural strength and imperfections.

Full-grain leather offers the greatest durability and water resistance. It molds to the foot over time but often requires a break-in period.

Split Leather & Suede: The Breathable Workhorse

Split leather is created from the inner layer of the hide after the top grain has been removed. It has a napped, fuzzy finish on both sides.

Suede is a common type of split leather. It is softer, more flexible, and more breathable than full-grain leather but is less resistant to water and stains.

Nubuck Leather: The Velvet-Finish Hybrid

Nubuck is technically a top-grain leather, meaning it comes from the durable outer hide. However, its surface is lightly sanded to create a soft, velvety feel.

This process gives it a feel similar to suede but with greater durability and water resistance. It offers a good balance of strength and comfort.

Oiled (Pull-Up) Leather: The Weather-Resistant Specialist

This is typically full-grain leather that has been saturated with oils and waxes. This treatment deeply nourishes the leather, making it exceptionally supple and water-resistant.

When the leather is stretched or pulled, the oils cause the color to lighten, creating a distinct "pull-up" effect. This is the premier choice for wet and harsh conditions.

Understanding the Trade-offs: Leather vs. Synthetics

While leather is a traditional staple, modern synthetic materials offer their own set of advantages and are often combined with leather.

The Case for Leather: Durability and Form-Fitting

Leather's primary advantage is its unmatched durability and abrasion resistance, especially in full-grain form. Its natural fiber structure allows it to conform to the wearer's foot over time, providing a custom fit.

The Case for Synthetics (Nylon & Mesh): Lightweight & Breathable

Materials like nylon fabric and mesh are significantly lighter than leather. They offer superior breathability, making them ideal for warm environments or highly active roles.

Key Compromises to Consider

While synthetics excel in breathability, they typically offer less durability than high-quality leather. Untreated fabrics can also be more prone to staining and absorbing liquids.

Conversely, the most durable full-grain leathers are often heavier and less breathable than their synthetic counterparts. The choice always involves a trade-off.

Making the Right Choice for Your Environment

Selecting the right upper material depends entirely on the demands of your job.

- If your primary focus is maximum durability and abrasion resistance: Choose full-grain leather for its dense, unaltered fiber structure.

- If your primary focus is breathability in dry conditions: Split leather, suede, or safety shoes with synthetic mesh panels offer the best air circulation.

- If your primary focus is water resistance: Oiled leather or specifically engineered waterproof synthetic uppers are the most effective choices.

- If your primary focus is lightweight comfort and flexibility: Nubuck leather and modern synthetics like nylon provide comfort with less break-in time.

By understanding these fundamental differences, you can select footwear that serves as a genuine tool for your specific job.

Summary Table:

| Leather Type | Key Characteristics | Best For |

|---|---|---|

| Full-Grain Leather | Maximum durability, abrasion & water resistance | Heavy-duty, high-abrasion environments |

| Split Leather / Suede | Soft, breathable, flexible | Dry conditions requiring comfort & airflow |

| Nubuck Leather | Durable top-grain with soft, velvety finish | Balance of strength, comfort, and style |

| Oiled (Pull-Up) Leather | Supple, deeply water-resistant, 'pull-up' effect | Wet, harsh, and outdoor conditions |

Need safety shoes that match your exact work conditions?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise ensures you get the right leather or synthetic upper for optimal performance, durability, and comfort.

Contact our experts today to discuss your specific needs and explore our production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- What is the OSHA standard for safety-toe boots? Ensuring Compliance and Worker Protection

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime

- How does the structural design of industrial-grade safety shoes provide protection? Engineering Foot Health at Work