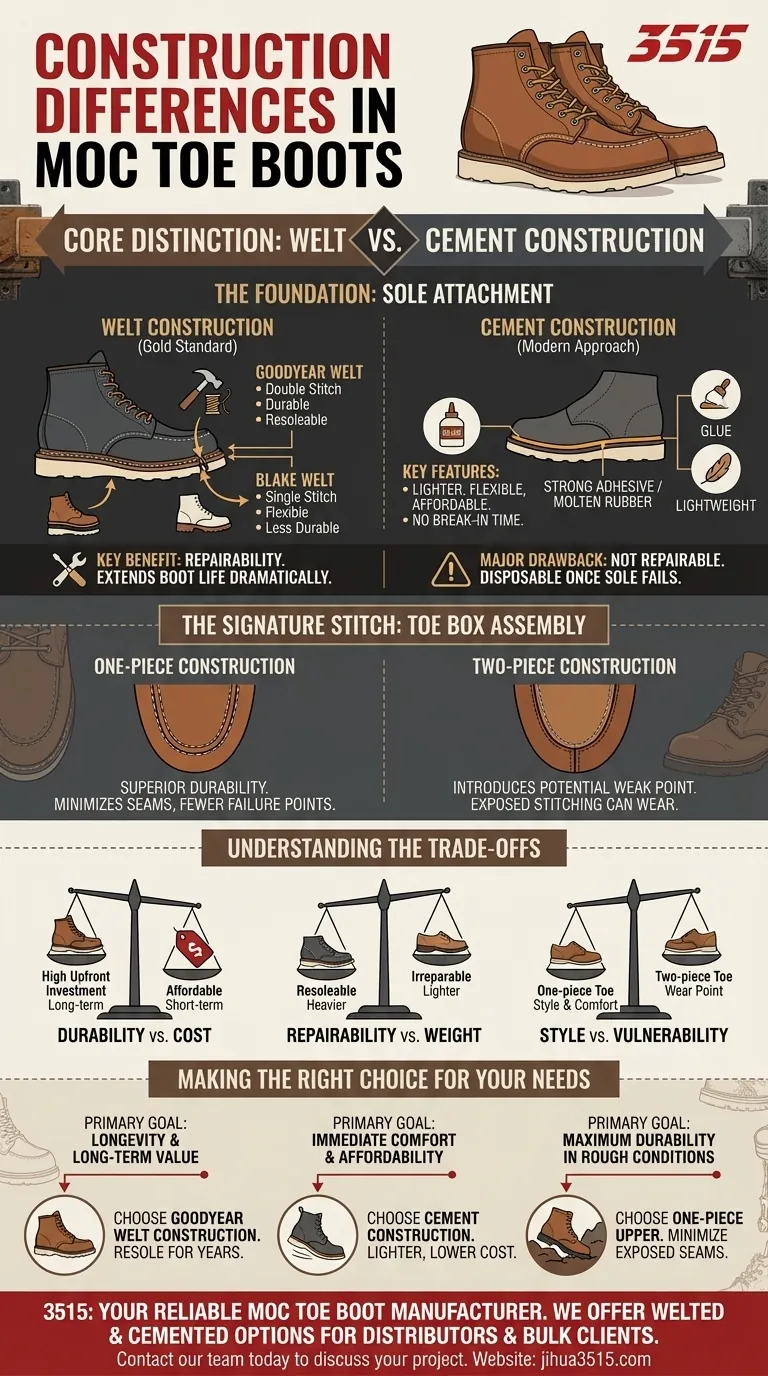

At their core, the construction differences in moc toe boots come down to two critical areas: how the sole is attached to the upper part of the boot and how the signature U-shaped toe box is assembled. The most significant distinction lies between a durable, repairable welt construction and a lightweight, affordable cement construction.

The most crucial decision you will make is choosing between a boot that can be repaired and last for years (welted) and one that prioritizes immediate comfort and a lower price (cemented). This single choice dictates the boot's long-term value and lifespan.

The Foundation: How the Sole Attaches to the Boot

The method used to join the sole to the boot's upper is the primary driver of durability, repairability, and cost. This is the boot's engineering foundation.

Welt Construction (The Gold Standard)

Welt construction involves stitching a sturdy strip of material, typically leather, to both the upper and the sole. This creates an incredibly strong and water-resistant bond.

There are two main types. A Goodyear welt is considered the most durable, using two independent stitches, which also makes resoling easier. A Blake welt uses a single stitch, offering more flexibility but slightly less durability.

The key benefit of any welted construction is repairability. When the outsole wears down, a cobbler can remove it and stitch on a new one, dramatically extending the life of the boot.

Cement Construction (The Modern Approach)

Cement construction is a simpler and more cost-effective method where the upper is attached to the sole using a strong adhesive or molten rubber.

This process results in a boot that is significantly lighter and more flexible right out of the box, often requiring less break-in time.

The major drawback is that once the sole is damaged or worn through, it is typically not repairable. The bond is permanent, making the boot disposable once the sole fails.

The Signature Stitch: How the Toe Box is Assembled

The "moc" in moc toe refers to the moccasin-style stitching that forms a U-shape on top of the toe box. This feature provides added flexibility, but how it's built also impacts durability.

One-Piece Construction

In a one-piece design, the U-shaped seam is stitched directly onto a single, continuous piece of leather that forms the front of the boot.

This method is superior for durability because it minimizes the number of seams. Fewer seams mean fewer potential points of failure from abrasion or stress.

Two-Piece Construction

A two-piece design involves joining two separate pieces of leather with an exposed seam along the top of the toe box.

While functional, this construction introduces a potential weak point. The exposed stitching is more susceptible to catching on objects and wearing out, which can compromise the boot's integrity over time.

Understanding the Trade-offs

Choosing a boot construction is a matter of balancing competing priorities. There is no single "best" method; there is only the best method for your specific needs.

Durability vs. Cost

Goodyear welted boots represent a significant upfront investment but pay off in longevity. Cemented boots are much more affordable but should be considered a short-to-medium-term purchase.

Repairability vs. Weight

A key advantage of a welted boot is its ability to be resoled multiple times. However, the extra materials used in a welt add weight and stiffness. Cemented boots are lighter and more comfortable initially but are fundamentally irreparable.

Style vs. Vulnerability

The iconic moc toe stitching that provides comfort and style is also a natural point of wear. For high-abrasion environments, a two-piece construction with its exposed top seam is a greater liability than a smoother, one-piece design.

Making the Right Choice for Your Needs

To select the correct boot, you must first define your primary goal.

- If your primary focus is longevity and long-term value: Choose a boot with a Goodyear welt construction, as it can be resoled for years of service.

- If your primary focus is immediate comfort and affordability: A cement construction will provide a lighter, more flexible boot at a lower initial cost.

- If your primary focus is maximum durability in rough conditions: Seek out a one-piece upper to minimize exposed seams that can fail under stress.

Ultimately, understanding these construction methods empowers you to look past style and choose a boot built for its intended purpose.

Summary Table:

| Construction Type | Key Feature | Durability & Repairability | Best For |

|---|---|---|---|

| Goodyear Welt | Stitched sole construction | High; can be resoled multiple times | Long-term value, rugged use |

| Cement Construction | Adhesive-bonded sole | Low; typically not repairable | Immediate comfort, affordability |

| One-Piece Toe | Single piece of leather | High; fewer seams, less wear | Maximum durability in rough conditions |

| Two-Piece Toe | Two pieces joined by a seam | Moderate; exposed stitching can wear | Style and flexibility |

Need a reliable partner for your moc toe boot production?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in both welted and cemented construction ensures you get the right balance of durability, comfort, and value for your target market.

Let's discuss your project: Contact our team today to get a quote and learn how we can help you build better boots.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- Do snake bite boots work? Your Ultimate Guide to Effective Snake Bite Protection

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene