At its core, the choice of a midsole material involves a direct trade-off between lightweight comfort and long-term durability. The most common materials are Ethylene-Vinyl Acetate (EVA) for cushioning and Polyurethane (PU) for resilience, often supplemented by rigid shanks for foundational support and protection.

The midsole is the engine of your footwear, and its material dictates the balance between immediate comfort, lasting support, and overall weight. Understanding this balance is critical for selecting footwear that meets the demands of your specific environment.

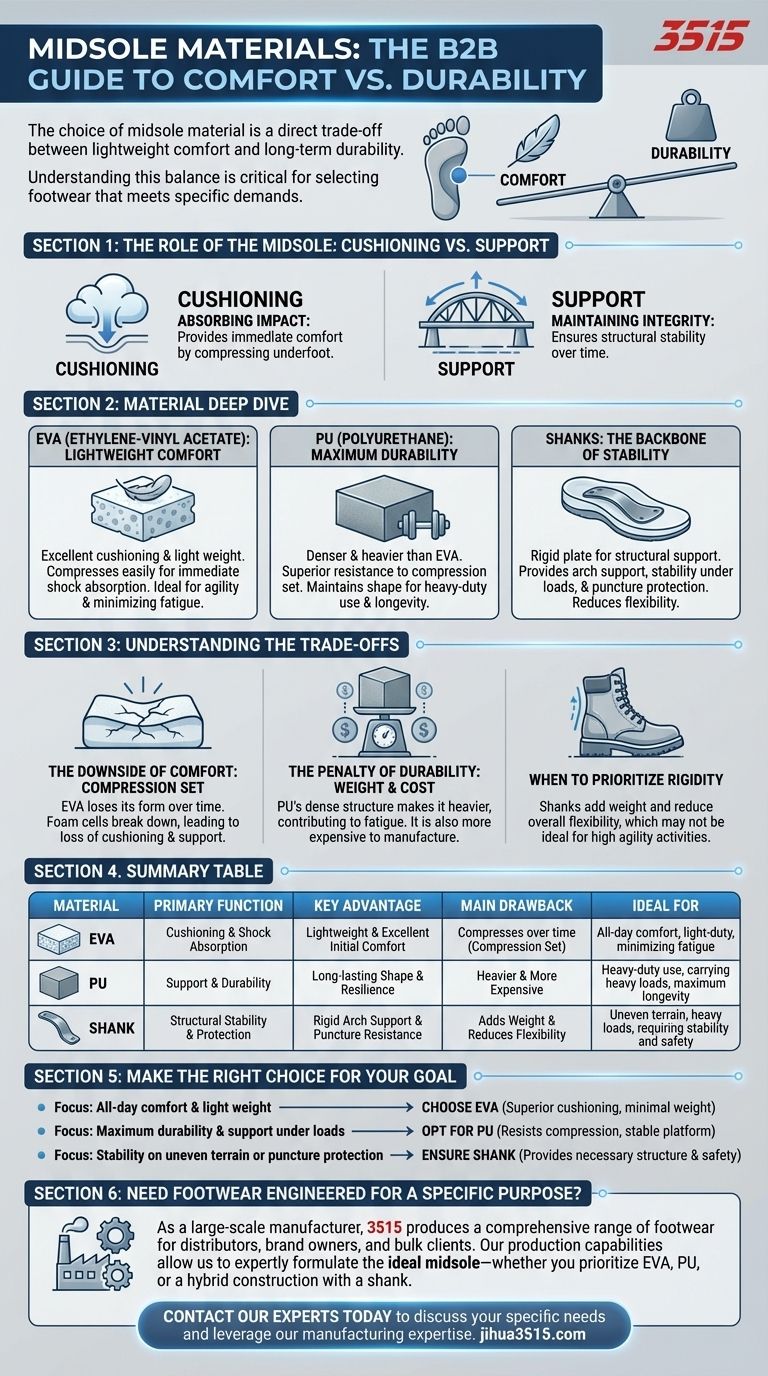

The Role of the Midsole: Cushioning vs. Support

A midsole serves two primary functions: absorbing impact (cushioning) and maintaining the structural integrity of the footwear (support). The material used determines how well it performs each function over time.

EVA: The Standard for Lightweight Comfort

EVA is a foam material known for its excellent cushioning and light weight. It provides immediate comfort by compressing easily underfoot to absorb shock.

This compression-resistant nature makes it ideal for roles where agility and minimizing fatigue are priorities. However, this same quality is also its primary weakness.

Polyurethane (PU): The Choice for Maximum Durability

Polyurethane (PU) is a denser, heavier foam compared to EVA. Its primary advantage is superior durability and resistance to compression set.

Footwear with PU midsoles maintains its shape and supportive structure for much longer, making it the preferred choice for heavy-duty use or for individuals carrying substantial gear.

Shanks: The Backbone of Stability

A shank is not a cushioning material but a rigid plate, often made of steel, embedded within the midsole. Its purpose is purely structural.

Shanks provide crucial arch support, improve stability when carrying heavy loads, and offer protection from puncture hazards from below.

Understanding the Trade-offs

Choosing the right midsole means acknowledging the inherent compromises between different materials. No single material excels at everything.

The Downside of Comfort: Compression Set

The primary drawback of EVA is that it eventually loses its form. Over time and with repeated impact, the foam cells break down and do not rebound, a phenomenon known as "compression set."

This leads to a loss of both cushioning and support, requiring the footwear to be replaced more frequently to maintain performance.

The Penalty of Durability: Weight and Cost

The robustness of Polyurethane (PU) comes at a cost. Its dense structure makes it significantly heavier than EVA, which can contribute to fatigue over a long day.

PU is also generally more expensive to manufacture, which is reflected in the final price of the footwear.

When to Prioritize Rigidity

While essential for certain applications, a steel shank adds weight and rigidity. This reduces the overall flexibility of the footwear, which may be undesirable for activities requiring high agility or a more natural foot-flex.

Making the Right Choice for Your Goal

Your primary use case should dictate your choice of midsole construction.

- If your primary focus is all-day comfort and light weight: Choose footwear with an EVA midsole for its superior cushioning and minimal weight penalty.

- If your primary focus is maximum durability and support under heavy loads: Opt for a Polyurethane (PU) midsole that will resist compression and provide a stable platform for years.

- If your primary focus is stability on uneven terrain or puncture protection: Ensure your footwear includes a rigid shank to provide the necessary structure and safety.

Ultimately, understanding these materials empowers you to select footwear as a piece of purpose-built equipment.

Summary Table:

| Material | Primary Function | Key Advantage | Main Drawback | Ideal For |

|---|---|---|---|---|

| EVA (Ethylene-Vinyl Acetate) | Cushioning & Shock Absorption | Lightweight & Excellent Initial Comfort | Compresses over time (Compression Set) | All-day comfort, light-duty activities, minimizing fatigue |

| PU (Polyurethane) | Support & Durability | Long-lasting Shape & Resilience | Heavier & More Expensive | Heavy-duty use, carrying heavy loads, maximum longevity |

| Shank (e.g., Steel) | Structural Stability & Protection | Rigid Arch Support & Puncture Resistance | Adds Weight & Reduces Flexibility | Uneven terrain, heavy loads, requiring stability and safety |

Need footwear engineered for a specific purpose?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to expertly formulate the ideal midsole—whether you prioritize EVA's lightweight comfort, PU's rugged durability, or a hybrid construction with a shank for ultimate stability.

Let us help you build the perfect product for your market.

Contact our experts today to discuss your specific needs and leverage our manufacturing expertise.

Visual Guide

Related Products

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What footwear is recommended for day rides in mountain biking during winter? Maximize Warmth & Performance

- Why is a tethered AFO emulator preferred over a standalone device? Unlocking High-Power Assistance Research

- How should riders choose the best motorcycle boots? Match Your Riding Style for Maximum Safety & Comfort

- In what way does a Computer-Aided Design (CAD) system improve material utilization? Boost Efficiency and Reduce Waste

- How do integrated high-sensitivity force plates ensure data accuracy? Precision Tech for Footwear Dynamic Testing

- What are the practical benefits of dynamic facility layout optimization? Boost Large-Scale Footwear Production Agility

- Why is a laboratory grinding mill required for leather hexavalent chromium tests? Achieve Precision and Compliance

- What are the key considerations when buying motorcycle boots? Find the Perfect Fit for Safety & Style