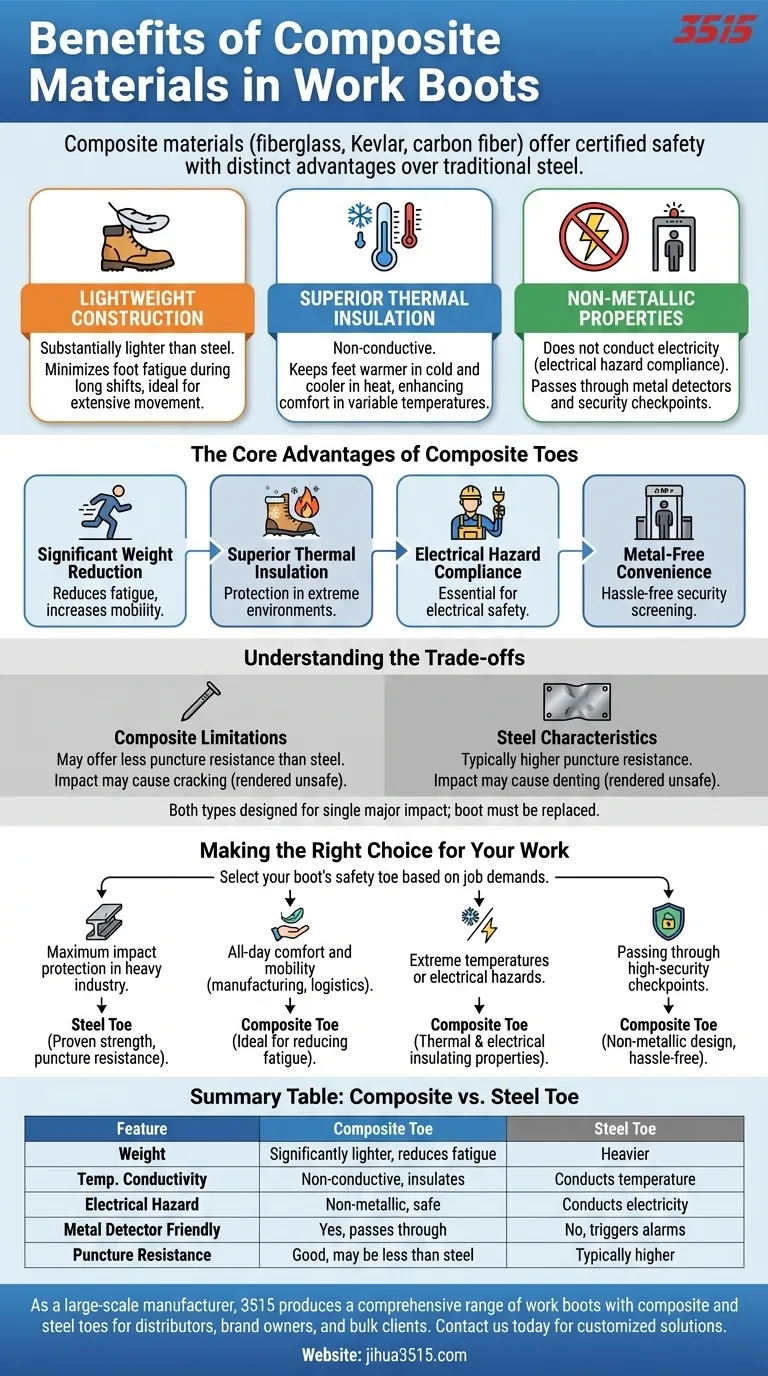

The primary benefits of composite materials in work boots are their lightweight construction, non-metallic properties, and superior temperature insulation compared to traditional steel. Materials like fiberglass, Kevlar, and carbon fiber provide certified safety protection without the added weight or conductivity of metal.

The core decision between composite and steel toes is not about which is universally "better," but which is right for your specific work environment. Composite materials excel where all-day comfort, temperature extremes, and metal-free requirements are the dominant concerns.

The Core Advantages of Composite Toes

A safety toe made from composite materials is engineered to provide specific advantages that are critical in many modern workplaces.

Significant Weight Reduction

Composite materials are substantially lighter than steel. This reduction in weight minimizes foot fatigue over long shifts, making them ideal for workers who are constantly on their feet or covering long distances.

Superior Thermal Insulation

Unlike steel, composites do not conduct temperature. This means your feet stay warmer in cold conditions and cooler in hot environments, providing a significant comfort advantage for outdoor or temperature-variable work.

Electrical Hazard Compliance

Because they are non-metallic, composite toes do not conduct electricity. This makes them an essential choice for electricians and anyone working in environments with a risk of electrical hazards.

Metal-Free Convenience

The non-metallic nature of composite boots allows workers to pass through metal detectors and security checkpoints without issue. This is a major benefit in fields like security, logistics, and airport ground operations.

Understanding the Trade-offs

While composite materials offer clear benefits, it's crucial to understand their limitations to make an informed safety decision.

Puncture Resistance

While strong and compliant with impact safety standards, some composite materials may offer less puncture resistance than a comparable steel plate or toe. Steel often provides a higher degree of protection against sharp objects from below.

Durability After a Major Impact

Both steel and composite toes are designed for a single major impact. After such an event, the boot's safety integrity is compromised and it must be replaced. A key difference is that steel may dent, while a composite toe is more likely to crack, but both outcomes render the boot unsafe for future use.

The Role of the Boot's Upper

The safety toe is only one part of the boot's protective system. The durability, water resistance, and overall lifespan of a work boot are heavily dependent on the upper material, with full-grain leather being a common choice for its robustness and ability to mold to the foot.

Making the Right Choice for Your Work

Select your boot's safety toe based on the primary demands of your job.

- If your primary focus is maximum impact protection in heavy industry: Steel remains a top choice for its proven strength and puncture resistance.

- If your primary focus is all-day comfort and mobility: Composite is ideal for reducing fatigue during long shifts in manufacturing, logistics, or general contracting.

- If your primary focus is working in extreme temperatures or around electricity: Composite is the definitive choice for its thermal and electrical insulating properties.

- If your primary focus is passing through high-security checkpoints: Composite's non-metallic design is essential for hassle-free screening.

Ultimately, understanding your specific job hazards and daily demands is the key to selecting the right protection for your feet.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Weight | Significantly lighter, reduces fatigue | Heavier |

| Temperature Conductivity | Non-conductive, insulates from heat/cold | Conducts temperature |

| Electrical Hazard | Non-metallic, safe for electrical work | Conducts electricity |

| Metal Detector Friendly | Yes, passes through checkpoints | No, triggers alarms |

| Puncture Resistance | Good, but may be less than steel | Typically higher |

As a large-scale manufacturer, 3515 produces a comprehensive range of work boots with composite and steel toes for distributors, brand owners, and bulk clients. Whether you need lightweight composite boots for all-day comfort or steel-toed boots for maximum impact protection, our production capabilities cover all types of safety footwear. Contact us today to discuss your specific requirements and get a customized solution that meets your safety and comfort needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the proper way to clean work boots? Extend Boot Life with Gentle Cleaning

- What design features should be considered for additional protection and convenience in work boots? Enhance Your Safety and Comfort

- How can lacing techniques improve boot fit? Unlock a Custom, Blister-Free Fit

- Why is comfort important in work boots for women? Boost Productivity & Safety

- What safety boots are recommended for the oil and gas industry? Essential Features for Hazardous Sites

- Why is breaking in work boots important? Ensure Long-Term Comfort and Durability

- What should be considered when choosing heavy duty work boots? The Ultimate Guide for Safety & Comfort

- Why is proper care and maintenance important for leather work boots? Extend Lifespan & Protect Your Investment