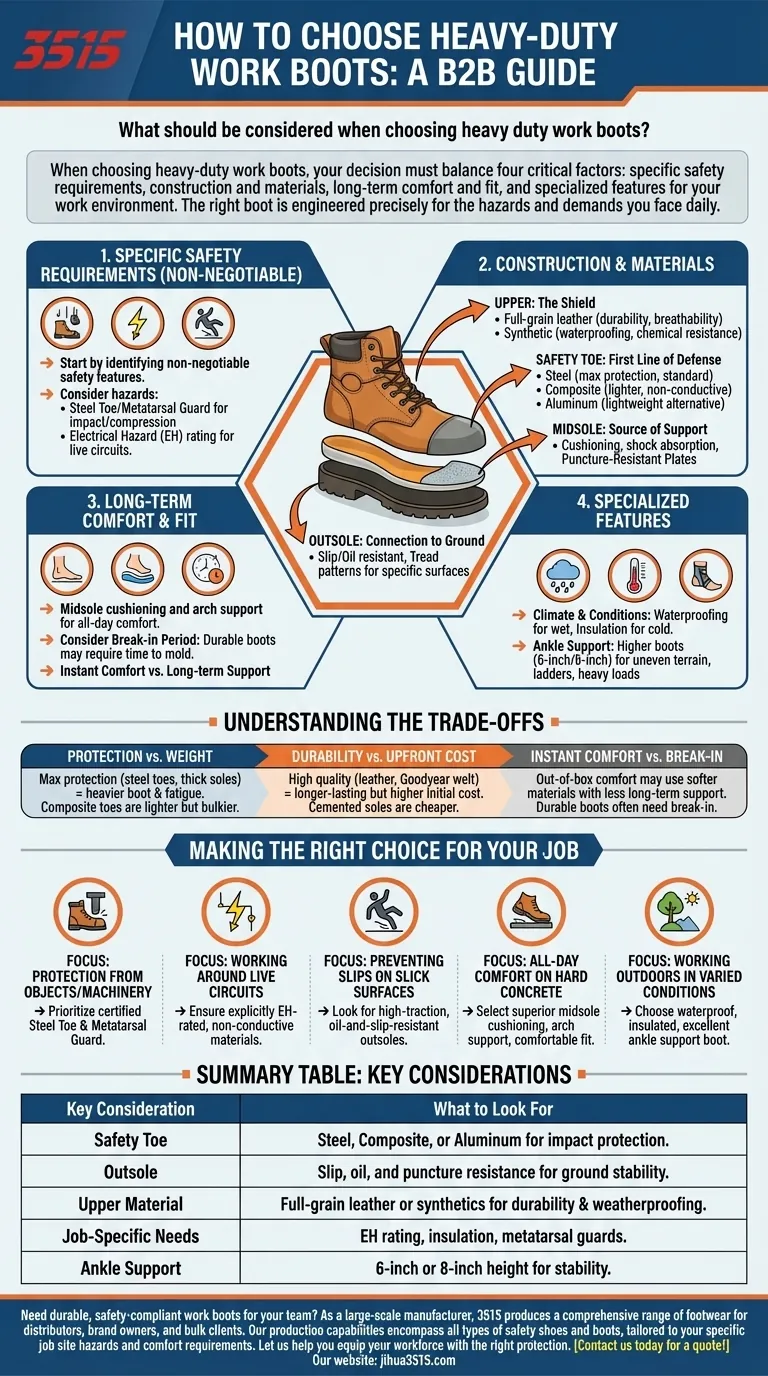

When choosing heavy-duty work boots, your decision must balance four critical factors: the specific safety requirements of your job, the boot's construction and materials, long-term comfort and fit, and specialized features for your work environment. The right boot is not simply the most rugged one available, but the one engineered precisely for the hazards and demands you face daily.

The most effective way to select a work boot is to think of it as a piece of specialized safety equipment. Start by identifying the non-negotiable safety features your job requires, and only then filter by comfort, materials, and climate-specific needs.

Deconstructing the Work Boot: Core Components

A heavy-duty work boot is a system of components working together to protect you. Understanding these parts allows you to assess a boot's true capability.

The Safety Toe: Your First Line of Defense

The safety toe is the most recognized feature, designed to protect you from impact and compression.

- Steel Toes offer the maximum level of protection and have been the industry standard for decades.

- Composite Toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel and don't conduct heat or cold, making them ideal for extreme temperatures or metal-free work environments.

- Aluminum Toes provide a lightweight alternative to steel but meet the same safety standards.

The Outsole: Your Connection to the Ground

The outsole dictates your stability and is your primary defense against slips and punctures. Look for materials and tread patterns designed for the surfaces you walk on, such as oil-resistant soles for automotive or manufacturing work.

The Midsole: The Source of Support

Sandwiched between the insole and outsole, the midsole provides cushioning and absorbs shock. Some heavy-duty boots feature puncture-resistant plates in the midsole to protect your foot from sharp objects like nails.

The Upper: The Shield for Your Foot

The upper part of the boot protects you from the elements, abrasions, and splashes. Full-grain leather is a classic choice for its durability and breathability, while synthetic materials may offer better waterproofing or chemical resistance.

Matching the Boot to Your Environment

Beyond the basic components, you must align the boot's features with the specific conditions of your workplace. This is where a generic "good boot" becomes the "right boot" for you.

Assessing Workplace Hazards

Your first consideration must be the unique risks of your job.

If you work around heavy machinery or falling objects, a steel toe cap and even a metatarsal guard (which protects the top of your foot) are essential. For electricians, boots with an Electrical Hazard (EH) rating are non-negotiable.

Considering Climate and Conditions

Working outdoors or in unconditioned spaces requires features that manage the climate.

Waterproofing is critical for wet environments to keep your feet dry and prevent discomfort. For cold climates, insulation provides necessary warmth to maintain safety and circulation.

The Importance of Ankle Support

Jobs that involve walking on uneven terrain, climbing ladders, or carrying heavy loads demand excellent ankle support. Higher boots (6-inch or 8-inch) provide greater stability and reduce the risk of sprains and twists.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one involves understanding the inherent compromises.

Protection vs. Weight

Features like steel toes and thick, puncture-proof soles offer maximum protection but add significant weight. This can lead to fatigue over a long shift. Composite toes offer a lighter alternative but may be bulkier.

Durability vs. Upfront Cost

High-quality materials like full-grain leather and Goodyear welt construction result in a more durable, longer-lasting boot that can be resoled. However, this quality comes with a higher initial price compared to boots with cemented soles.

Instant Comfort vs. a Break-in Period

The most durable, supportive boots often require a break-in period as the stiff leather molds to your foot. Boots that feel perfectly comfortable out of the box may use softer materials that offer less long-term support and durability.

Making the Right Choice for Your Job

Filter your options based on your primary daily requirements to find the boot that best serves your needs.

- If your primary focus is protection from falling objects and machinery: Prioritize boots with certified steel toe caps and consider a metatarsal guard for maximum safety.

- If your primary focus is working around live circuits: Ensure the boots are explicitly EH-rated and built with non-conductive materials.

- If your primary focus is preventing slips on slick surfaces: Look for boots with a high-traction, oil-and-slip-resistant outsole designed for your specific floor type.

- If your primary focus is all-day comfort on hard concrete: Select a boot with superior midsole cushioning, good arch support, and a comfortable fit right out of the box.

- If your primary focus is working outdoors in varied conditions: Choose a waterproof, potentially insulated boot with excellent ankle support to handle weather and terrain.

Investing the time to match your boot's features to your daily demands is the single best way to ensure your safety, comfort, and productivity on the job.

Summary Table:

| Key Consideration | What to Look For |

|---|---|

| Safety Toe | Steel, Composite, or Aluminum for impact protection. |

| Outsole | Slip, oil, and puncture resistance for ground stability. |

| Upper Material | Full-grain leather or synthetics for durability & weatherproofing. |

| Job-Specific Needs | EH rating for electricians, insulation for cold, metatarsal guards. |

| Ankle Support | 6-inch or 8-inch height for stability on uneven terrain. |

Need durable, safety-compliant work boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, tailored to your specific job site hazards and comfort requirements. Let us help you equip your workforce with the right protection. Contact us today for a quote!

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the essential features all work boots should have regardless of gender? Non-Negotiable Safety & Support

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety