Breaking in new work boots is a critical process for two primary reasons: it molds the stiff, protective materials to the unique shape of your feet for long-term comfort, and it prevents premature damage to the boot's internal lining. This essential step ensures the boot performs correctly from the first day of wear and maintains its structural integrity over time.

The core purpose of breaking in a work boot is to transition it from a generic, factory-shaped object into a piece of equipment customized to your specific foot anatomy. This process is not about enduring pain, but about preventing it.

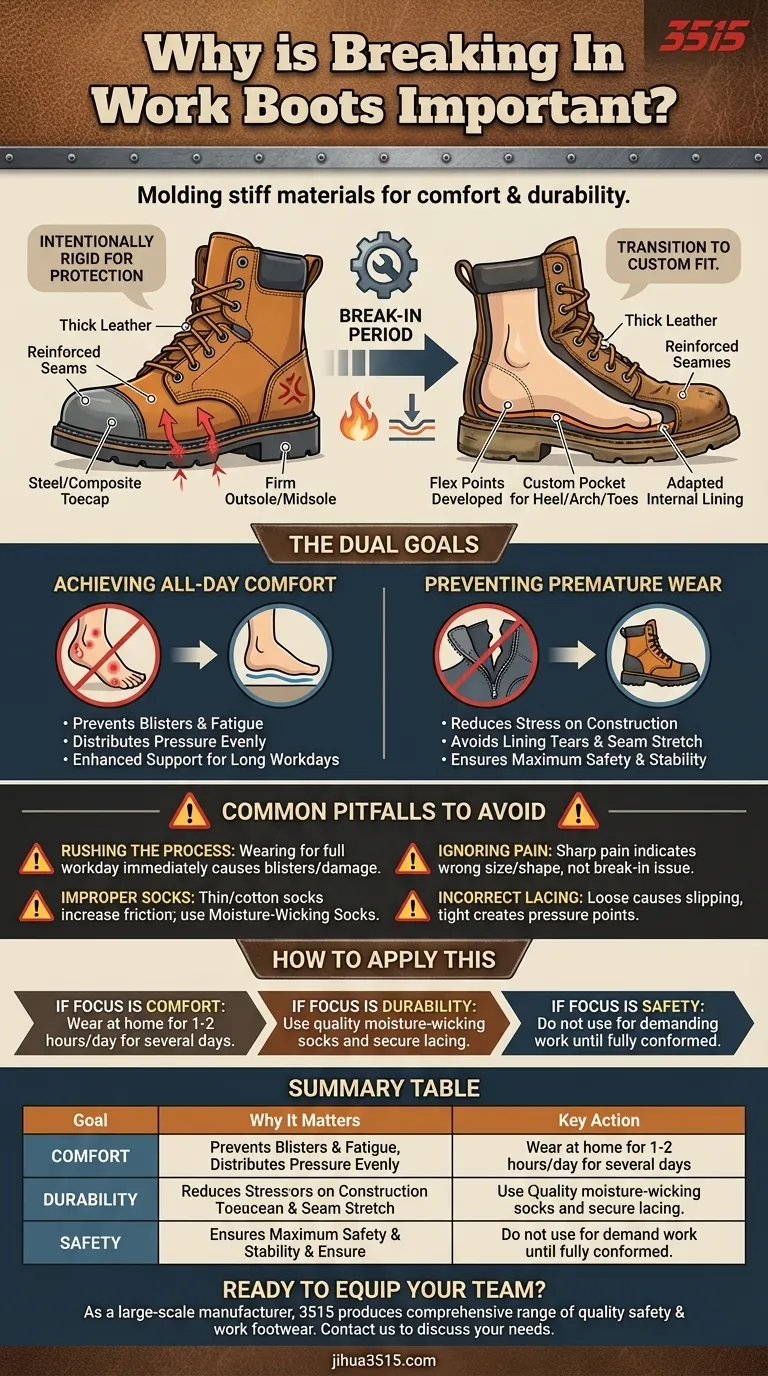

Why New Boots Require a Break-In Period

A brand-new work boot is intentionally rigid. Its primary function is protection, which requires durable materials like thick leather, reinforced seams, and safety components like steel or composite toecaps.

The Initial Stiffness of Protective Materials

New leather and synthetic uppers have not yet developed flex points. The outsole and midsole are often firm to provide foundational support and puncture resistance. This initial rigidity is a sign of quality, not a flaw.

From Generic Shape to Custom Fit

Every foot is different. The break-in period uses the gentle heat and pressure from your foot to gradually soften and shape the boot's materials. This creates a custom pocket for your heel, arch, and toes.

The Dual Goals: Comfort and Durability

Failing to break in boots properly compromises both your physical well-being and the lifespan of your investment. The process directly addresses these two interconnected goals.

Achieving All-Day Comfort

An unbroken-in boot creates friction and pressure points. This leads directly to blisters, foot fatigue, and general discomfort. A properly molded boot distributes pressure evenly, providing the support you need for long workdays.

Preventing Premature Wear and Tear

Forcing a stiff boot through a full day of work puts immense stress on its construction. This can cause the internal lining to tear or seams to stretch and weaken prematurely. A gradual break-in allows these materials to adapt without being damaged.

Ensuring Maximum Safety and Support

A boot that doesn't conform to your foot cannot provide optimal support. This can lead to instability and increase the risk of an accident. Once broken in, the boot works with your foot's natural movement, enhancing stability and ensuring protective features are positioned correctly.

Common Pitfalls to Avoid

The break-in process is simple, but several common mistakes can undermine its effectiveness or even signal that you have the wrong boot entirely.

Rushing the Process

The most common mistake is wearing new boots for a full, active workday immediately. This is the fastest way to cause painful blisters and potentially damage the boot's lining.

Ignoring Signs of a Poor Fit

Discomfort is expected, but sharp, persistent pain is not. If you experience significant pain, it likely indicates the boot is the wrong size or shape for your foot, and no amount of breaking in will fix it.

Using Improper Socks

Wearing thin or cotton socks increases friction and retains moisture. Moisture-wicking socks are essential during the break-in period to keep feet dry, reduce friction, and prevent blisters.

Incorrect Lacing

Lacing that is too loose allows your foot to slide, causing friction. Lacing that is too tight creates pressure points. Adjust the lacing to be snug and secure without cutting off circulation.

How to Apply This to Your Boots

Your approach to breaking in your boots should align with your primary goal, whether it's immediate comfort or ensuring the longest possible lifespan for your gear.

- If your primary focus is avoiding pain: Wear your new boots around the house for just 1-2 hours at a time for several days before ever taking them to the job site.

- If your primary focus is long-term durability: Always use quality moisture-wicking socks and pay attention to a secure lacing pattern to minimize internal friction that can shred the boot's lining.

- If your primary focus is on-the-job safety: Do not wear the boots for demanding work until they feel fully conformed to your feet, as a proper fit is essential for stability and support.

Investing a small amount of time to properly break in your boots is the best way to guarantee their comfort, safety, and longevity.

Summary Table:

| Goal | Why It Matters | Key Action |

|---|---|---|

| Comfort | Prevents blisters and foot fatigue by molding the boot to your foot. | Wear boots for 1-2 hours at home initially. |

| Durability | Avoids premature damage to the boot's internal lining and seams. | Use quality socks and proper lacing to reduce friction. |

| Safety | Ensures optimal support and stability for on-the-job protection. | Do not use for demanding work until fully conformed. |

Ready to equip your team with durable, comfortable work boots designed for a smooth break-in?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work shoes and boots, built with quality materials that balance protection with long-term comfort.

Contact us today to discuss your specific needs and discover how we can be your reliable manufacturing partner.

Visual Guide

Related Products

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How long do work boots typically last? Maximize Lifespan & Safety

- Can you wear work boots every day? The Essential Guide to All-Day Comfort and Safety

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What is the difference between a cowboy boot and a work boot? Choosing the Right Footwear for Your Task