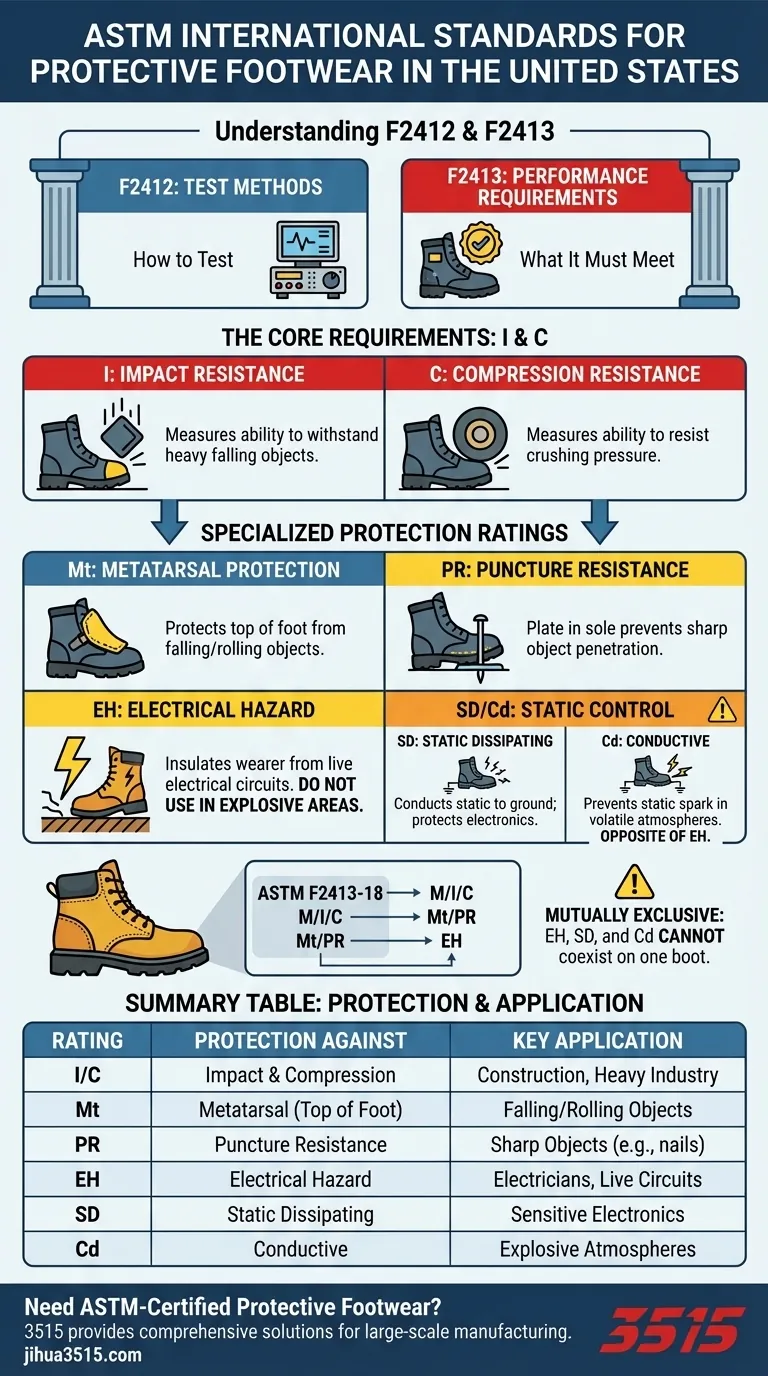

In the United States, the primary standards for protective footwear are ASTM F2412 and ASTM F2413. The most current version is designated as F2413-18. This standard establishes the minimum performance requirements for footwear to protect against a variety of workplace hazards, from impact and compression to electrical shock and punctures.

The key is to understand that these standards work as a system. ASTM F2412 defines how to test the footwear, while ASTM F2413 specifies the performance requirements the footwear must meet. A boot's label tells you exactly which F2413 requirements it has been certified for.

The Two Pillars of Footwear Safety

To properly select safety footwear, you must understand the distinct roles of the two core ASTM standards. They are not interchangeable; one sets the rules for testing, and the other sets the benchmark for passing those tests.

ASTM F2412: The Standard for Test Methods

This standard is the official rulebook for testing. It outlines the precise procedures, equipment, and conditions that labs must use to evaluate protective footwear.

By standardizing the test methods, ASTM F2412 ensures that a boot tested in one facility is evaluated the same way as a boot tested in another, providing consistency and reliability across the industry.

ASTM F2413: The Standard for Performance Requirements

This is the standard most users need to know. ASTM F2413 specifies the minimum performance criteria for a boot to be labeled as "protective footwear."

A boot cannot be considered ASTM-certified unless it first meets the basic requirements for impact and compression resistance for the toe area. It can then be tested for additional, specialized hazards.

Decoding the Safety Footwear Label

The label, typically found on the tongue of the boot, is a concise summary of its protective features. Understanding this code is the most critical part of choosing the right boot for your specific job. A compliant label will always be presented in a specific four-line format.

The Basics: Impact (I) and Compression (C)

Every boot certified to ASTM F2413 must provide protection against both impact and compression.

Impact (I) testing measures the toe cap's ability to withstand a heavy object falling on it. Compression (C) testing measures its ability to resist crushing pressure from a slow-moving, heavy rolling object.

Specialized Protection: Metatarsal (Mt) and Puncture Resistance (PR)

These ratings provide protection beyond the basic safety toe.

Metatarsal (Mt) guards protect the top of the foot (the metatarsal bones) from impact. This is crucial in environments where objects could drop or roll onto the foot.

Puncture Resistant (PR) footwear includes a plate within the sole to prevent sharp objects like nails from penetrating the bottom of the boot.

Electrical and Static Hazards: EH, SD, and Cd

This group of ratings deals with how the footwear interacts with electricity.

Electrical Hazard (EH) boots are designed to insulate the wearer from the ground, significantly reducing the risk of shock from stepping on a live electrical circuit.

Static Dissipating (SD) footwear is designed to safely conduct static electricity to the ground, preventing a harmful buildup that could damage sensitive electronics.

Conductive (Cd) footwear is the opposite of EH. It is designed to actively conduct static electricity away from the body and into the ground to prevent static spark in highly flammable or explosive environments.

Understanding the Common Pitfalls

Simply buying a boot with an ASTM label is not enough. Misunderstanding the ratings or their limitations can lead to a false sense of security and potential injury.

Not All Boots Protect Against All Hazards

A boot’s certification is specific. An EH-rated boot is not necessarily puncture-resistant unless it also carries the PR designation. You must match the boot's specific ratings to the specific hazards identified in your workplace risk assessment.

A Boot Cannot Have Opposing Ratings

It is impossible for a single pair of footwear to be rated for both Electrical Hazard (EH) and Conductive (Cd) or Static Dissipating (SD). Their functions are mutually exclusive—one is designed to insulate you, while the others are designed to conduct.

The Importance of Proper Fit

The ASTM F2413 standard specifies requirements for fit and function. A boot that fits poorly can be a hazard in itself, causing fatigue, blisters, or slips and falls. Proper performance relies on proper fit.

Making the Right Choice for Your Environment

Your choice must be driven by a clear understanding of your work environment's primary risks.

- If your primary focus is construction or heavy industry: You need footwear with, at minimum, Impact (I) and Compression (C) ratings, and likely Puncture Resistance (PR).

- If your primary focus is working as an electrician: You must select footwear specifically rated for Electrical Hazard (EH) to protect against accidental shock.

- If your primary focus is working with sensitive electronics: You should choose Static Dissipating (SD) footwear to protect the components from static discharge.

- If your primary focus is working in explosive or volatile atmospheres: You must use Conductive (Cd) footwear to prevent any possibility of a static spark.

- If your primary focus involves handling heavy rolling objects or falling tools: You should strongly consider Metatarsal (Mt) protection for the top of your foot.

By understanding how to read the label, you empower yourself to make an informed decision that directly addresses the real-world hazards you face.

Summary Table:

| ASTM Rating | What It Protects Against | Key Application |

|---|---|---|

| I/C | Impact & Compression | Construction, Heavy Industry |

| Mt | Metatarsal (Top of Foot) | Falling/Rolling Objects |

| PR | Puncture Resistance | Sharp Objects (e.g., nails) |

| EH | Electrical Hazard | Electricians, Live Circuits |

| SD | Static Dissipating | Sensitive Electronics |

| Cd | Conductive | Explosive Atmospheres |

Need ASTM-Certified Protective Footwear Tailored to Your Specific Hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, ensuring your workforce is protected against impact, compression, punctures, and electrical hazards.

Contact our expert team today for a consultation. We'll help you select or manufacture the perfect protective footwear to meet your exact ASTM requirements and keep your team safe.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the primary function of industrial pneumatic actuator systems in safety shoe gait perturbation research?

- Why is UHF Passive RFID Preferred Over Barcodes for Safety Boots in Farms? Boost Your Tracking Efficiency Today

- Do safety boots expire? Understand Their True Service Life for Maximum Protection

- Why is quality control important in safety footwear? Ensuring Life-Saving Protection on the Job

- What are the benefits of ergonomic safety shoes for older workers? Enhancing Stability and Joint Health for Ages 50-65

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- What are overboots and covers used for in protective footwear? Essential Protection for Hazardous Environments

- Why are industrial-grade safety shoes essential in concrete handling? Maximize Worker Protection and Traction