In short, quality control is the non-negotiable process that ensures safety footwear will actually perform as promised in a hazardous situation. It is the system of checks, tests, and standards that guarantees proper assembly and material integrity. This systematic rigor is what translates a safety rating into reliable, real-world protection, directly reducing the frequency and severity of workplace injuries.

Quality control is not merely a final inspection; it is a comprehensive system woven into every stage of production. It ensures that the safety features designed on paper are reliably executed in the physical product that protects a worker's life and limb.

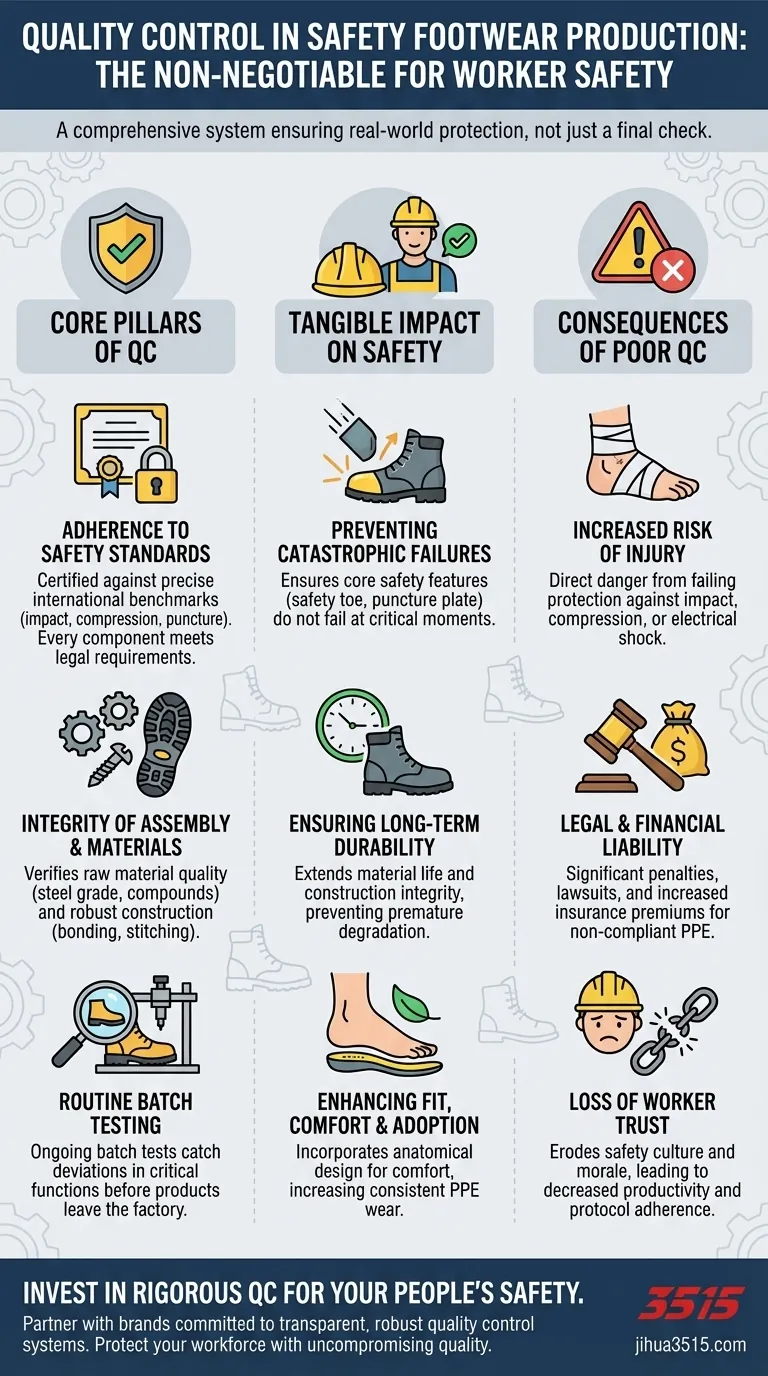

From Blueprint to Boot: The Core Pillars of QC

A safety boot's protective capability is only as strong as the quality control process that builds it. This process is built on three fundamental pillars that work together to ensure reliability from the design phase to the factory floor.

Adherence to Safety Standards

Safety footwear is not graded on opinion; it is certified against precise, internationally recognized standards. These standards dictate specific performance requirements for impact resistance, compression, puncture resistance, and more.

Effective quality control implements a system to ensure every component and assembly process meets or exceeds these legal and industrial benchmarks. It is the mechanism for accountability.

Integrity of Assembly and Materials

A certified design can easily fail if constructed with substandard materials or poor workmanship. QC protocols verify the raw materials, such as the grade of steel for a safety toe or the chemical compound for a slip-resistant sole.

Furthermore, QC oversees the assembly itself—ensuring adhesives create a permanent bond, stitching is robust, and protective components are seated correctly.

The Role of Routine Testing

Certification is based on initial testing, but quality control ensures performance remains consistent over thousands of units. This involves routine batch testing within the factory.

Critical safety functions, like impact resistance for falling objects or electrical hazard protection, are repeatedly tested to catch any deviation from the standard before a faulty product ever leaves the facility.

The Tangible Impact on Worker Safety

The consequences of quality control are felt directly by the end-user. The difference between a robust and a poor QC program can be the difference between a close call and a life-altering injury.

Preventing Catastrophic Failures

The primary role of QC is to prevent the absolute failure of a safety feature at a critical moment. A safety toe that shatters under impact or a sole that is punctured by a nail represents a catastrophic failure of the product's core promise.

Ensuring Long-Term Durability

A boot's safety features must remain effective for its entire expected service life. QC extends to material durability and construction integrity, ensuring the boot will not degrade prematurely and expose the worker to unexpected risks.

Enhancing Fit, Comfort, and Adoption

Advanced quality control also considers human factors. A poorly fitting boot can cause chronic pain and fatigue, leading workers to discard their personal protective equipment (PPE).

Top-tier manufacturers incorporate fit and comfort into their quality standards, using gender-specific anatomical designs (lasts) to ensure proper support. This significantly increases the likelihood that the footwear will be worn correctly and consistently.

The Consequences of Poor Quality Control

Ignoring or minimizing quality control introduces unacceptable risks not only for the worker but for the entire organization.

Increased Risk of Injury

This is the most direct and serious consequence. A boot that fails to protect against impact, compression, or electrical shock places the worker in immediate danger.

Legal and Financial Liability

Providing employees with inadequate or non-compliant PPE opens an organization to significant legal and financial penalties. A failure in quality control can lead to regulatory fines, lawsuits, and a dramatic increase in insurance premiums.

Loss of Worker Trust

When workers cannot trust their safety equipment, it erodes morale and damages the organization's safety culture. This lack of confidence can lead to decreased productivity and a reluctance to follow safety protocols.

Making the Right Choice for Your Organization

When selecting safety footwear, look beyond the marketing and inquire about the manufacturer's commitment to quality.

- If your primary focus is maximum safety and compliance: Demand clear documentation of testing and certification to specific, recognized standards.

- If your primary focus is worker adoption and long-term health: Prioritize manufacturers who invest in ergonomic design, proper fit, and high-quality, durable materials.

- If your primary focus is mitigating organizational risk: Partner with brands that demonstrate a transparent and robust quality control system, from material sourcing to final assembly testing.

Ultimately, investing in rigorous quality control is a direct investment in the safety and well-being of your people.

Summary Table:

| QC Pillar | Key Function | Impact on Safety |

|---|---|---|

| Adherence to Standards | Ensures certification to impact, compression, and puncture resistance benchmarks. | Guarantees the boot meets legal and performance requirements. |

| Material & Assembly Integrity | Verifies quality of components (steel toes, soles) and construction (stitching, bonding). | Prevents catastrophic failures from substandard materials or poor workmanship. |

| Routine Batch Testing | Conducts ongoing tests on production batches to maintain consistent performance. | Catches deviations before faulty products leave the factory, ensuring long-term reliability. |

Protect your workforce with uncompromising quality. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our robust quality control system is integrated into every production stage, from material sourcing to final assembly testing, ensuring every pair delivers the life-saving protection your workers depend on. Contact our team today to discuss your safety footwear needs and receive a customized solution that prioritizes safety, compliance, and durability.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture