The primary advantages of vulcanized skate shoes are their superior boardfeel, flexibility, and immediate grip. Because the sole is thin and cooked directly onto the shoe's upper, it requires almost no break-in time, offering unparalleled control for technical skating right out of the box.

The decision to skate a vulcanized shoe is a deliberate trade-off. You are choosing to prioritize maximum board control and sensitivity over high-impact cushioning and long-term durability.

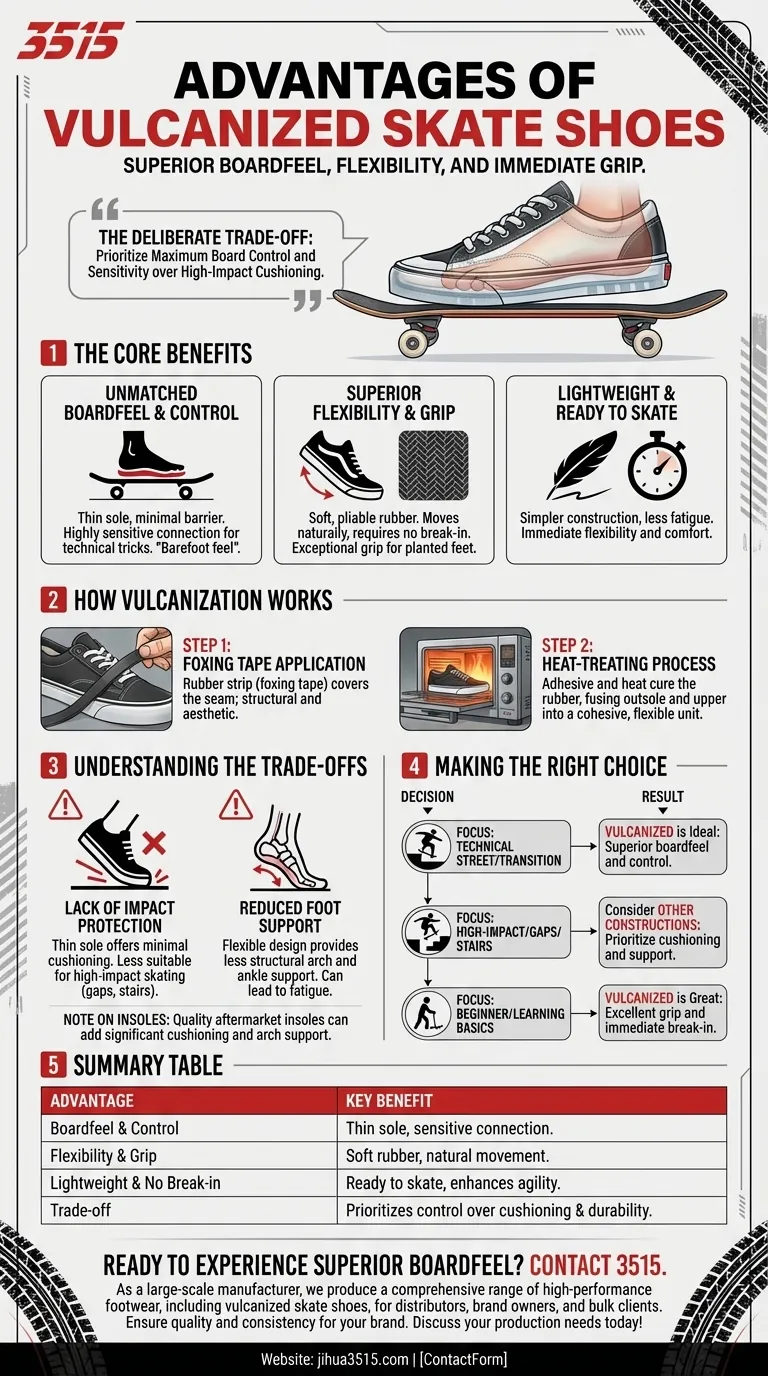

The Core Benefits of Vulcanization

The unique construction process of a vulcanized shoe is directly responsible for its distinct feel and performance characteristics. Skaters choose them for a very specific connection to their board.

Unmatched Boardfeel and Control

The thin, flat outsole is the defining feature of a vulcanized shoe. This minimal barrier between your foot and the board allows for a highly sensitive connection.

This design gives you a precise feel for the board's concave and edges, which is critical for technical tricks like flip-ins on ledges or navigating the transitions of a bowl. Many skaters describe it as the closest feeling to skating barefoot.

Superior Flexibility and Grip

The vulcanization process bakes the rubber sole, making it soft and pliable. This inherent flexibility allows the shoe to move naturally with your foot from the very first wear.

This soft rubber also provides an exceptional grip on the griptape, giving you the confidence that your feet will stay planted as you set up for tricks.

Lightweight and Ready to Skate

With less material and a simpler construction, vulcanized shoes are noticeably lightweight. This reduces fatigue and enhances the feeling of agility.

A significant advantage is the minimal break-in period. Unlike stiffer shoes, a vulcanized sole is flexible and comfortable almost immediately, allowing you to skate them at their full potential much faster.

How Vulcanized Construction Works

Understanding the manufacturing process clarifies why these shoes feel the way they do. It's a simple, time-tested method focused on bonding rubber through heat.

The Role of Foxing Tape

A key visual identifier of a vulcanized shoe is the foxing tape. This is the strip of rubber that runs level around the entire shoe, covering the seam where the upper meets the outsole.

This tape isn't just for looks; it's a structural part of the shoe that is fused in place during the heating process.

The Heat-Treating Process

In essence, the shoe's outsole is attached to the upper with adhesive and then baked in a high-temperature oven.

This process, known as vulcanization, causes a chemical reaction that cures and hardens the rubber, fusing all the parts into a single, cohesive, and flexible unit.

Understanding the Trade-offs

No shoe construction is perfect for every situation. The very features that make vulcanized shoes great for boardfeel create disadvantages in other areas.

Lack of Impact Protection

The thin sole that provides excellent boardfeel offers very little cushioning. This makes vulcanized shoes less suitable for skating high-impact obstacles like large stair sets or gaps.

Reduced Foot Support

The highly flexible design provides less structural support for your arches and ankles. While this aids in board control, it can lead to more foot fatigue during long sessions.

A Note on Insoles

Many of these impact and support issues can be partially mitigated. Investing in a quality pair of aftermarket insoles can add significant cushioning and arch support to a vulcanized shoe.

Making the Right Choice for Your Skating

The ideal shoe depends entirely on your personal skating style and priorities.

- If your primary focus is technical street or transition skating: The superior boardfeel and flexibility of a vulcanized shoe are a significant advantage for precise control.

- If your primary focus is skating large gaps, stairs, or high-impact spots: You will benefit more from the added cushioning and support that vulcanized shoes traditionally lack.

- If you are a beginner learning basic maneuvers: The excellent grip and immediate break-in of a vulcanized shoe can help you feel and control your board more effectively.

Ultimately, understanding this fundamental balance between boardfeel and protection is key to choosing the right tool for your feet.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Boardfeel & Control | Thin sole for a sensitive, barefoot-like connection to the board. |

| Flexibility & Grip | Soft, pliable rubber provides excellent grip and natural foot movement. |

| Lightweight & No Break-in | Ready to skate immediately, reducing fatigue and enhancing agility. |

| Trade-off | Prioritizes control over high-impact cushioning and long-term durability. |

Ready to experience the superior boardfeel of vulcanized skate shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of vulcanized shoes and boots, ensuring quality and consistency for your brand.

Contact us today to discuss your production needs and bring exceptional skate footwear to your market!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance