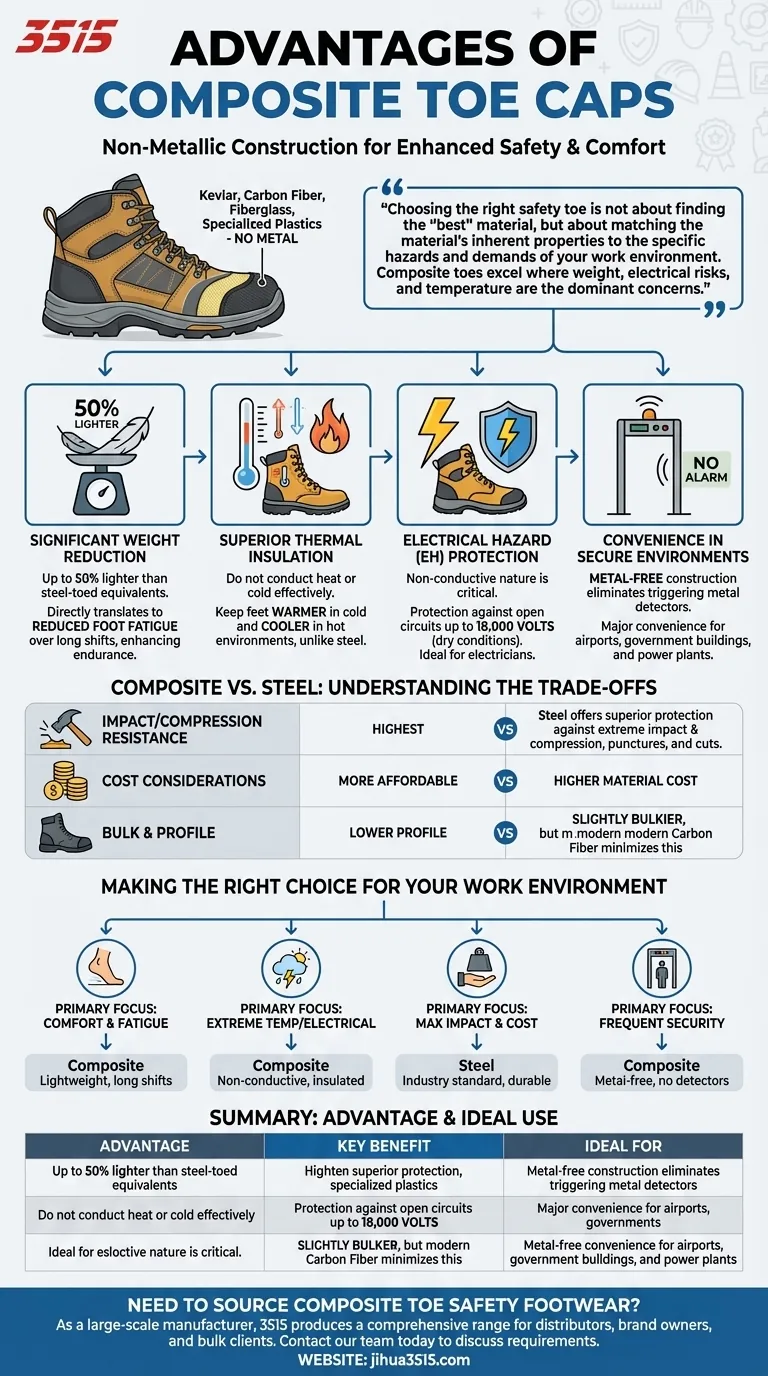

The primary advantages of composite toe caps stem from their non-metallic construction. This makes them significantly lighter than steel, non-conductive of electricity and temperature, and ideal for environments with metal detectors. These benefits provide a unique combination of safety and all-day comfort.

Choosing the right safety toe is not about finding the "best" material, but about matching the material's inherent properties to the specific hazards and demands of your work environment. Composite toes excel where weight, electrical risks, and temperature are the dominant concerns.

The Core Benefits of Non-Metallic Construction

The defining feature of a composite toe cap is what it lacks: metal. This fundamental difference is the source of its key advantages, derived from materials like Kevlar, carbon fiber, fiberglass, and specialized plastics.

Significant Weight Reduction

Composite toe caps are the lightest form of certified protection available. This can reduce the total weight of a work boot by as much as 50% compared to a steel-toed equivalent.

This weight savings directly translates to reduced foot fatigue over long shifts, enhancing comfort and endurance for workers who are constantly on their feet.

Superior Thermal Insulation

Unlike steel, composite materials do not conduct heat or cold effectively. This property offers a significant comfort advantage in extreme weather.

In cold environments, composite toes help keep feet warmer, while in hot conditions, they do not absorb and retain heat from the surrounding environment.

Electrical Hazard (EH) Protection

The non-conductive nature of composite materials is a critical safety feature. They do not conduct electricity, making them the default choice for electricians and anyone working near live circuits.

Certain models are rated to protect against open circuits of up to 18,000 volts in dry conditions, providing a crucial layer of defense against electrical shock.

Convenience in Secure Environments

Because they are metal-free, composite toe boots will not trigger metal detectors. This is a major convenience for professionals who work in secure facilities like airports, government buildings, or power plants, eliminating a daily hassle.

Understanding the Trade-offs: Composite vs. Steel

To make an informed decision, it is crucial to understand where composite toes differ from their traditional steel counterparts. Neither is universally superior; they are simply suited for different priorities.

Impact and Compression Resistance

While all certified safety toes must meet the same minimum safety standards, steel generally offers the highest level of protection against extreme impact and compression.

Steel can often withstand a greater single force before fracturing and provides superior resistance to punctures and cuts. If your work involves a high risk of heavy falling objects, steel remains the benchmark for absolute strength.

Cost Considerations

As a general rule, steel toe boots are more affordable. The manufacturing process and material costs for steel are typically lower than for advanced composites like carbon fiber or Kevlar.

Bulk and Profile

Historically, composite toe caps needed to be slightly bulkier than steel to provide the same level of certified protection. However, modern materials like carbon fiber have largely closed this gap, enabling strong, lightweight, and low-profile designs.

Making the Right Choice for Your Work Environment

The best choice depends entirely on a clear assessment of your daily tasks and potential risks.

- If your primary focus is all-day comfort and minimizing fatigue: The significant weight reduction of composite toes makes them the ideal option for long shifts.

- If your primary focus is working in extreme temperatures or around electrical hazards: Composite toes are the superior choice due to their non-conductive properties.

- If your primary focus is maximum impact protection and cost-effectiveness: Traditional steel toes remain the industry standard for ultimate durability and value.

- If your primary focus is passing through security checkpoints frequently: Composite toes offer a clear advantage by not triggering metal detectors.

By understanding these core differences, you can confidently select the safety footwear that truly aligns with your specific protection and comfort needs.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Lightweight | Reduces foot fatigue, enhances comfort | Long shifts, workers on their feet |

| Thermal Insulation | Does not conduct heat or cold | Extreme weather environments |

| Electrical Hazard (EH) Rated | Non-conductive, protects against shock | Electricians, live circuit work |

| Metal-Free | Will not trigger metal detectors | Airports, secure facilities, power plants |

Need to source composite toe safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe footwear, ensuring you get the right combination of safety, comfort, and durability for your market. Contact our team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What additional protections does S1P provide over S1? The Crucial Safety Feature You Need

- How do professional safety shoes provide core protection in heavy industrial environments like shipyards? Explained

- How are safety Wellington boots designed for comfort? Engineered for All-Day Wear and Fatigue Reduction

- What protective role do industrial-grade safety shoes play during metal material residue cleaning operations?

- Why is height an important factor in fire boots? The Key to Ankle Stability and Fall Prevention

- Why is slip resistance an important factor in safety footwear? Prevent Slips and Falls in the Workplace

- What are the two main organizations for safety footwear standards? Ensure OSHA Compliance with the Right Standard

- Why is the ASTM D790 standard used to evaluate the flexural performance of safety shoe toe cap materials? Guide to ASTM D790