At their core, composite and carbon composite safety toes offer three primary advantages over traditional steel. They are non-metallic, making them ideal for high-security environments; they are significantly lighter, reducing foot fatigue over a long day; and they do not conduct temperature or electricity, providing superior comfort and safety in extreme weather or around electrical hazards.

The decision to choose a composite toe over a steel toe is not just about meeting a safety standard. It's about selecting a specialized material whose unique properties—thermal insulation, light weight, and electrical resistance—are better suited to the specific demands of your work environment.

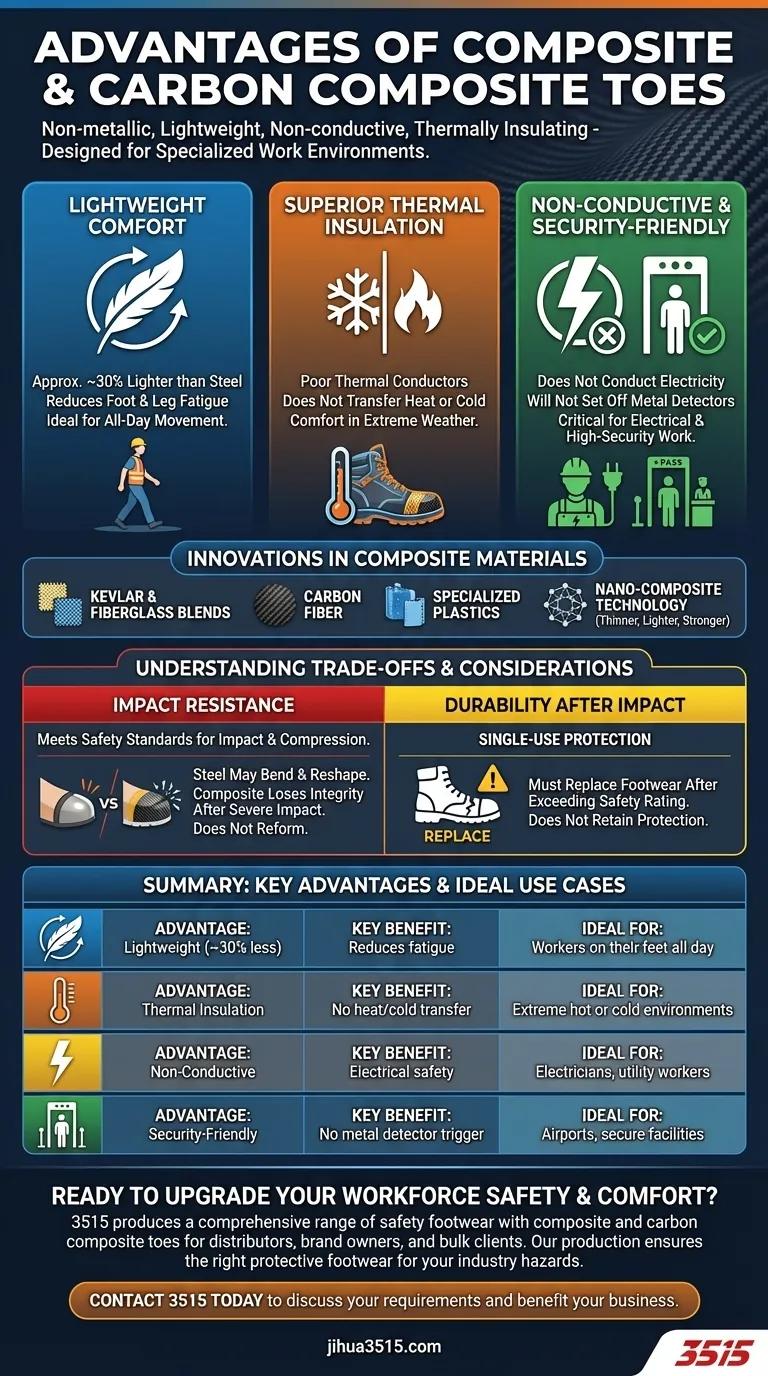

The Core Advantages of Non-Metallic Safety Toes

Lightweight for All-Day Comfort

Composite safety toes are approximately 30% lighter than their steel counterparts. This weight reduction directly translates to less strain on your feet and legs, significantly reducing fatigue during long shifts.

This makes them an excellent choice for workers who are constantly on the move.

Superior Thermal Insulation

Unlike metal, composite materials are poor thermal conductors. This means they do not transfer heat or cold from the outside environment to your feet.

In extreme hot or cold weather conditions, this property provides a major advantage in comfort and safety over steel toes.

Non-Conductive for Electrical Safety

The non-metallic nature of composite toes means they do not conduct electricity.

This is a critical safety feature for electricians, utility workers, and anyone working in environments where accidental contact with live electrical circuits is a risk.

Security and Convenience

Because they contain no metal, footwear with composite or carbon composite toes will not set off metal detectors.

This is a significant convenience for individuals who frequently pass through security checkpoints in airports, government buildings, or secure industrial facilities.

Innovations in Composite Materials

From Kevlar to Carbon Fiber

Modern composite toes are engineered from a blend of advanced, non-metallic materials. These can include Kevlar, carbon fiber, fiberglass, and specialized plastics.

This combination allows them to meet stringent safety standards (like ASTM F2413) without the weight and conductivity of steel.

The Rise of Nano-Composites

The latest innovation is the nano-composite toe. By using nanotechnology in the manufacturing process, the walls of the toe cap can be made much thinner and lighter.

This results in the strongest and lightest safety toes available, providing more room inside the shoe for a more comfortable and less bulky fit.

Understanding the Trade-offs

Impact Resistance vs. Steel

While composite toes are certified to meet the same safety standards for impact and compression as steel toes, there is a key difference in how they respond to extreme force.

After a significant impact, a steel toe may bend but can often be reshaped. A composite toe that has been compromised by a severe impact does not bend or reform and its structural integrity is lost.

Durability After Impact

It's critical to understand that once a composite toe has sustained an impact that exceeds its safety rating, the footwear must be replaced.

The material is designed to protect you from that single event, but unlike metal, it does not retain its protective qualities after a failure.

Making the Right Choice for Your Environment

Choosing the correct safety toe depends entirely on the specific hazards and requirements of your job.

- If your primary focus is working in high-security areas or with electrical hazards: The non-metallic, non-conductive properties of composite toes make them the definitive choice.

- If your primary focus is all-day comfort or work in extreme temperatures: The lighter weight and superior thermal insulation of composite toes offer a clear advantage.

- If your primary focus is maximum protection in an environment with extreme crush hazards: While composites meet the standard, steel is often perceived as providing a slight edge in ultimate impact resistance.

Ultimately, selecting the right safety toe is about matching the material's inherent strengths to your daily professional needs.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Lightweight | ~30% lighter than steel, reduces fatigue | Workers on their feet all day |

| Thermal Insulation | Does not conduct heat or cold | Extreme hot or cold environments |

| Non-Conductive | Will not conduct electricity | Electricians, utility workers |

| Security-Friendly | Will not set off metal detectors | Airports, secure facilities |

Ready to upgrade your workforce's safety and comfort?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with composite and carbon composite toes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get the right protective footwear, tailored to your specific industry hazards.

Contact 3515 today to discuss your requirements and discover how our expertise can benefit your business.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What materials are used in safety shoe toe protection? Steel, Composite, or Aluminum?

- What are the disadvantages of using fabrics in safety shoe uppers? Balancing Comfort with Durability

- What are the advantages of nano composite toes? Lightweight, Comfortable, and Certified Safety

- What are the key requirements for ASTM F2413 conforming safety footwear? A Guide to Selecting the Right Protection

- What standards must safety toe boots meet? Ensure Your Footwear Meets ASTM F2413

- What designs are available for oil resistant safety boots? Find the Perfect Fit for Your Industry

- How long do firefighter boots typically last? Extend Their Lifespan for Maximum Safety

- How does the design of specialized work shoes and safety boots facilitate the effective use of PPE? Streamline Your Safety