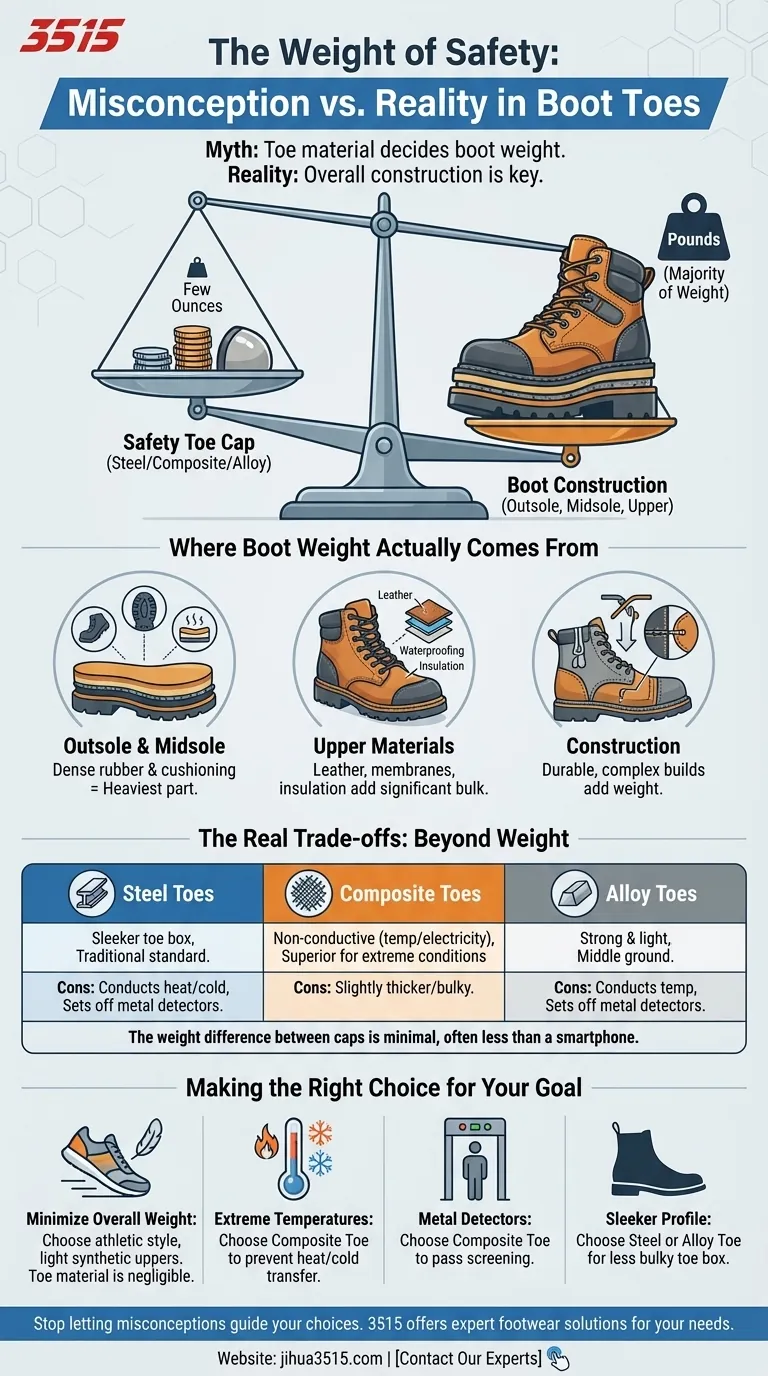

The most common misconception is that the choice between a steel, composite, or alloy toe is the deciding factor in a boot's overall weight. While there are slight differences, the reality is that the safety toe material contributes very little to the total weight you feel on your feet at the end of a long day.

The core truth is that a boot's weight is determined by its overall construction—the outsole, midsole, and upper materials—not by the few ounces that differentiate one type of safety toe from another.

The Myth of the "Heavy" Safety Toe

Many people blame the safety toe for a heavy, fatiguing boot. This is an understandable but incorrect assumption that can lead you to overlook the features that truly matter for comfort.

Quantifying the Actual Difference

The weight difference between a steel toe cap and a composite toe cap is typically measured in ounces, not pounds.

This variation is often less than the weight of your smartphone. When distributed across a multi-pound boot, this difference becomes practically unnoticeable during a workday.

Perception vs. Reality

The myth likely persists from older boot designs where heavy steel toes were paired with equally heavy, inflexible construction.

Today, modern manufacturing allows for strong, lightweight components across the entire boot. The safety toe is no longer the primary contributor to weight.

Where Boot Weight Actually Comes From

To find a genuinely lightweight boot, you must look beyond the toe cap and analyze the entire boot system. These components are the true drivers of weight.

The Outsole and Midsole

The thick rubber of the outsole and the dense cushioning of the midsole make up the vast majority of a work boot's weight.

Materials designed for high durability, slip resistance, and puncture protection are inherently heavy. This is the foundation of the boot and its heaviest part.

Upper Materials and Construction

The materials used for the boot's upper—such as thick, full-grain leather, waterproofing membranes, and insulation—add significant weight.

A heavily insulated, waterproof leather boot will always be heavier than an unlined boot made of synthetic mesh, regardless of the safety toe inside.

Understanding the Real Trade-offs

The choice between safety toe materials isn't about weight; it's about properties that affect your specific work environment.

Steel Toes

Steel is the traditional standard. It can be made thinner than composite materials while providing the same level of impact protection, which can result in a less bulky toe box.

However, steel readily conducts both heat and cold, which can be a major disadvantage in extreme temperature environments. It will also set off metal detectors.

Composite Toes

Composite toes are made from non-metal materials like Kevlar, carbon fiber, or plastic. Their key advantage is that they do not conduct electricity or temperature.

This makes them the superior choice for electricians or those working in extreme cold or heat. To achieve the same strength rating as steel, they are often slightly thicker or bulkier.

Alloy Toes

Alloy toes, typically made from aluminum or titanium, offer a middle ground. They are lighter than steel but stronger than composite.

This allows for a thin, protective toe box similar to steel without as much of the weight, though they still conduct temperature and will set off metal detectors.

Making the Right Choice for Your Goal

Stop focusing on the perceived weight of the toe cap and start evaluating the boot based on its features and your specific needs.

- If your primary focus is minimizing overall weight: Look at athletic-style safety shoes with light synthetic uppers and flexible cement construction, as the toe material's impact is negligible.

- If your primary focus is working in extreme temperatures: Choose a boot with a composite toe to prevent heat or cold from transferring to your feet.

- If your primary focus is passing through metal detectors: A composite toe is the only option that will not set off security screening.

- If your primary focus is a sleeker, less bulky toe box: A steel or alloy toe can often provide the required protection in a slimmer profile.

Choosing the right boot means understanding that all its parts work together as a complete system for your safety and comfort.

Summary Table:

| Misconception | Reality |

|---|---|

| Safety toe material is the main factor in boot weight. | The outsole, midsole, and upper materials are the primary drivers of weight. |

| Steel toes are significantly heavier than composite. | The weight difference is minimal, often just a few ounces. |

| Choosing a lighter toe cap will make a boot feel much lighter. | The overall boot design and construction have a far greater impact on comfort and fatigue. |

| The "heaviness" of a boot comes from the toe cap. | Heaviness is a result of the entire boot system, including durability features. |

Stop letting misconceptions guide your safety footwear choices. As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in boot construction ensures you get the right balance of protection, comfort, and weight for your specific needs. Let us help you select or manufacture the perfect safety boot. Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- How do integrated sensing devices within safety shoes contribute to product lifecycle management? Boost Safety & ROI

- How do you interpret ASTM safety shoe ratings? A Guide to Matching Footwear to Your Job's Hazards

- How can you identify if a safety shoe is OSHA approved? Decode the ASTM Label for Compliance

- What are the key differences between S4/S5 and other classes? A Guide to Waterproof vs. Breathable Safety Boots

- What are the primary functions of industrial-grade safety shoes? Protect Workers in Grinding & Cutting Operations

- How does the slip resistance of safety shoe outsoles contribute to worker safety in limestone mining dumping areas?

- What technical characteristics should protective footwear possess to reduce onychomycosis risk? Top Selection Tips

- Why choose composite toe shoes? Lighter, non-conductive safety for long shifts.