The primary reasons to choose composite toe shoes over steel toe are for their lighter weight, enhanced comfort during long shifts, and non-metallic properties. These features prevent them from conducting electricity or setting off metal detectors, making them the superior choice for specific professions where these factors are critical safety or convenience issues.

The choice between composite and steel toe is not about which is "better," but which is right for your specific job hazards and daily activities. Composite toes prioritize lightweight comfort and insulation from temperature and electricity, while steel toes offer the absolute maximum in impact and compression protection.

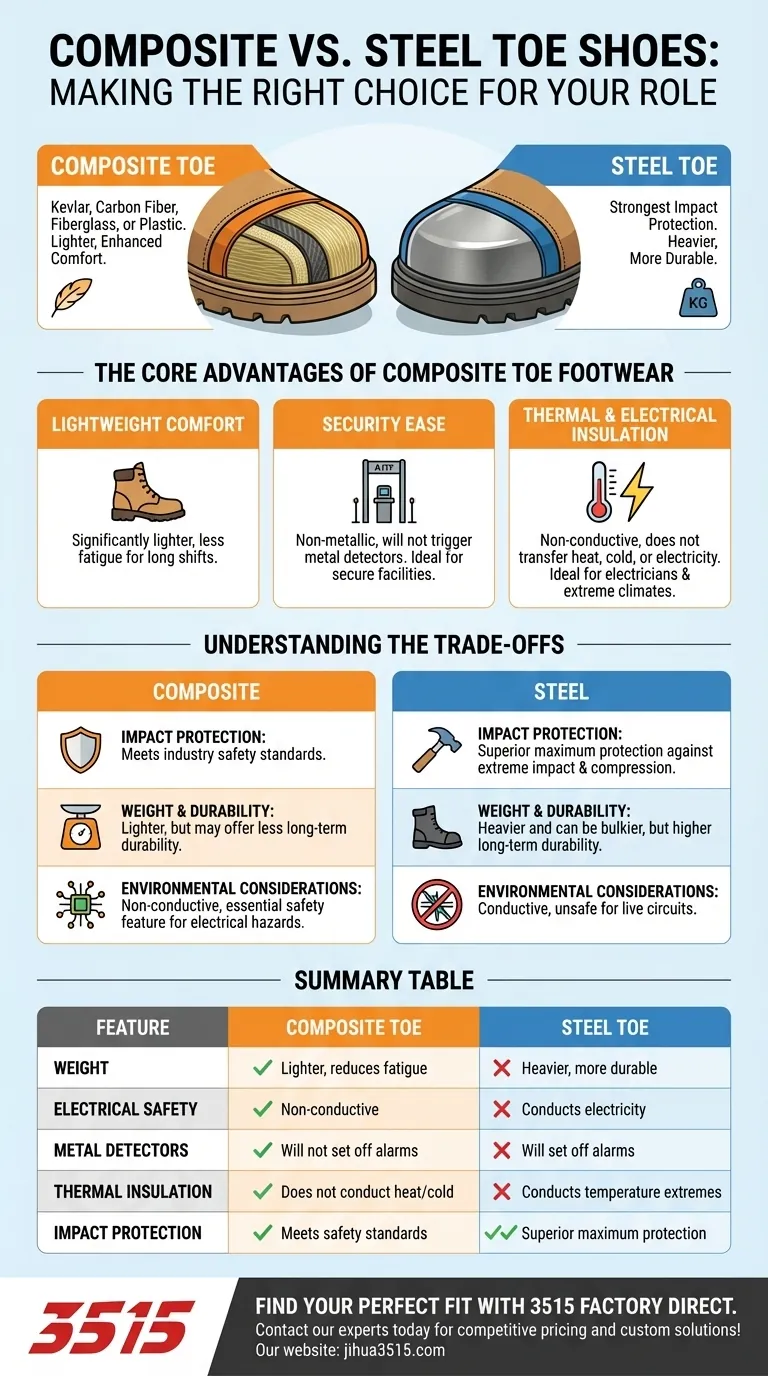

The Core Advantages of Composite Toe Footwear

The decision to opt for a composite toe comes down to balancing protection with the demands of your daily work environment. Composite materials offer a unique set of benefits that steel cannot match.

Lightweight Comfort for All-Day Wear

Composite safety toes are crafted from non-metallic materials like Kevlar, carbon fiber, fiberglass, or plastic.

This construction results in a significantly lighter shoe compared to its steel counterpart. For professionals on their feet for long hours, this reduction in weight directly translates to less fatigue and greater overall comfort.

Navigating Security with Ease

Because they contain no metal, composite toe shoes will not trigger metal detectors.

This is a crucial advantage for airport workers, security personnel, and anyone working in a secured facility that requires frequent screening. It eliminates the daily hassle of removing and replacing footwear.

Superior Thermal and Electrical Insulation

Unlike steel, the materials in composite toes do not conduct heat, cold, or electricity.

This makes them the ideal choice for electricians, as they provide an added layer of protection against electrical hazards. It also means they are far more comfortable in extreme hot or cold climates, as they won't transfer outside temperatures to your feet.

Understanding the Trade-offs: Composite vs. Steel

Choosing the right safety toe requires an objective look at the limitations and compromises involved. The best choice for a security guard is often the wrong choice for a heavy machinery operator.

The Critical Factor of Impact Protection

Steel toe footwear offers the strongest possible protection against extreme impact and compression. While both types must meet industry safety standards, steel provides a higher ceiling of defense.

For high-risk industries like construction, manufacturing, or roles involving heavy machinery, the superior protective capability of steel is often non-negotiable.

Weight and Durability

The primary trade-off for steel's superior strength is its weight. Steel toes are noticeably heavier and can be bulkier than composite models.

Conversely, while composite toes are lighter, they may not offer the same long-term durability against constant, heavy abuse as a classic steel-reinforced boot.

Environmental Considerations

The conductive properties of steel make it an unsafe choice for electricians or anyone working with live circuits.

In contrast, the non-conductive nature of composite materials makes them an essential safety feature in those same environments.

Making the Right Choice for Your Role

Selecting the proper safety toe is a critical decision that directly impacts your safety and comfort at work. Use your primary job function as your guide.

- If your primary focus is maximum impact protection: Steel toe is the undisputed choice, especially if you work around heavy machinery, falling objects, or in heavy construction.

- If your primary focus is all-day comfort and mobility: Composite toe is the superior option, significantly reducing foot fatigue over long shifts.

- If your primary focus is electrical hazard safety: You must choose a non-metallic composite toe to eliminate the risk of electrical conductivity.

- If your primary focus is passing through metal detectors: Composite toe will save you significant time and hassle in secure environments.

Understanding these core differences empowers you to select the safety footwear that truly serves the unique demands of your work environment.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Weight | Lighter, reduces fatigue | Heavier, more durable |

| Electrical Safety | Non-conductive, ideal for electricians | Conducts electricity, a hazard |

| Metal Detectors | Will not set off alarms | Will set off alarms |

| Thermal Insulation | Does not conduct heat or cold | Conducts temperature extremes |

| Impact Protection | Meets safety standards | Superior maximum protection |

Find Your Perfect Fit with 3515 Factory Direct

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether your team needs the lightweight comfort of composite toes or the maximum protection of steel toes, we have the production capabilities to meet your exact specifications.

Let us help you equip your workforce with the right safety shoes for their specific job hazards. Contact our experts today for competitive pricing and custom solutions!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data