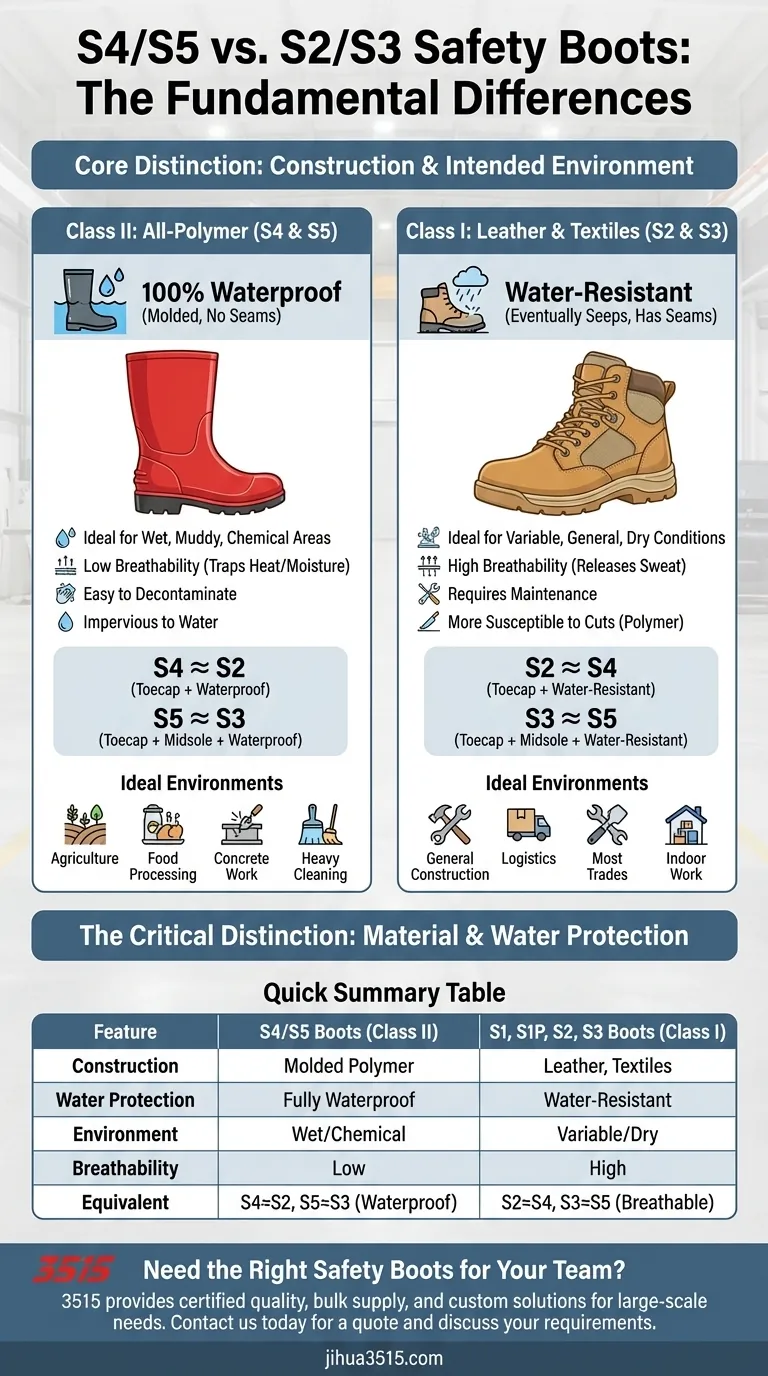

The fundamental difference is in their construction and intended environment. S4 and S5 safety boots are fully molded from a polymer like rubber or PVC, making them completely waterproof. They are the polymer equivalent of S2 and S3 boots, with S5 simply being an S4 boot with an added puncture-resistant midsole.

The critical distinction is not just a checklist of features, but the core material itself. S4/S5 boots are Class II footwear (all-polymer/rubber) designed for wet environments, whereas most other classes are Class I (leather and other materials) designed for more general or dry conditions.

The Defining Feature: Construction Material

The safety footwear standards are divided into two main classes based on how they are made. This distinction is the root of all the major differences.

Class II Footwear (S4 & S5)

These are boots, often in a "Wellington" style, manufactured from a single piece of molded polymer (like polyurethane, PVC, or rubber).

The key characteristic is that the material itself is 100% waterproof. There are no seams for water to penetrate, making them ideal for standing water, mud, or environments requiring frequent washing down.

Class I Footwear (SB, S1, S1P, S2, S3)

This category includes the vast majority of safety boots and shoes made from traditional materials like leather and textiles.

These materials are not inherently waterproof. While S2 and S3 boots have features to make them water-resistant, they will eventually allow moisture to seep through, especially at the seams. Their main advantage is superior breathability.

A Direct Comparison: S4/S5 vs. S2/S3

The references correctly state that S4/S5 protections correspond to S2/S3. This is the most useful direct comparison.

The Core Parallel

Think of them as two paths to a similar level of protection.

- An S4 boot has a safety toecap and is fully waterproof. It is the polymer equivalent of an S2 boot (toecap + water resistance).

- An S5 boot has a safety toecap, a puncture-resistant midsole, and is fully waterproof. It is the polymer equivalent of an S3 boot (toecap + puncture resistance + water resistance).

Waterproof vs. Water-Resistant

This is the most significant practical difference. An S5 boot will keep your foot dry while fully submerged for extended periods. An S3 boot will resist rain and splashes but will likely fail if you stand in a deep puddle for too long.

Breathability and Comfort

The trade-off for being completely waterproof is a lack of breathability. S4/S5 boots trap moisture and heat, which can be uncomfortable during long shifts in warm conditions. S2/S3 boots, made of leather or textiles, allow perspiration to escape, keeping feet drier from the inside.

Understanding the Trade-offs

Choosing between these classes is not about which is "better," but which is appropriate for the task and environment.

When to Choose S4/S5

These boots excel in environments where the primary hazard is liquid. This includes agriculture, food processing, concrete work, and heavy-duty cleaning. Their seamless, non-porous surface is also easy to decontaminate.

When to Choose S3

The S3 boot is the most common all-around safety boot for a reason. It is the standard choice for general construction, logistics, and most trades where conditions are variable. It provides robust protection while offering significantly more all-day comfort and breathability than a polymer boot.

The Durability Factor

While polymer boots are impervious to water, they can be more susceptible to cuts and tears than high-quality leather. Conversely, leather requires maintenance (cleaning and conditioning) to maintain its water resistance and lifespan, whereas polymer does not.

Making the Right Choice for Your Environment

Your decision should be based entirely on the conditions you face most often.

- If your primary focus is working in wet, muddy, or chemical-heavy areas: Choose S4 or S5 for guaranteed waterproof protection.

- If your primary focus is all-purpose work in variable, damp conditions: An S3 boot offers the best balance of protection, water resistance, and comfort.

- If your primary focus is indoor work in a dry environment: An S1P boot provides the necessary safety features with maximum breathability.

Ultimately, choosing the right safety boot begins with matching its fundamental construction to your work environment.

Summary Table:

| Feature | S4 / S5 Boots (Class II) | S1, S1P, S2, S3 Boots (Class I) |

|---|---|---|

| Construction | Single-piece molded polymer (rubber/PVC) | Leather, textiles, and other materials |

| Water Protection | Fully Waterproof (ideal for submersion) | Water-Resistant (resists rain/splashes) |

| Primary Environment | Wet, muddy, chemical-heavy areas | Variable, general, or dry conditions |

| Breathability | Low (traps heat/moisture) | High (superior comfort for long shifts) |

| Equivalent Protection | S4 ≈ S2; S5 ≈ S3 (but with full waterproofing) | S2 ≈ S4; S3 ≈ S5 (but with breathability) |

| Ideal For | Agriculture, food processing, concrete work | General construction, logistics, indoor work |

Need the Right Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether your workforce requires fully waterproof S5 boots for harsh, wet conditions or breathable S3 boots for all-around comfort, we have the production capabilities and expertise to meet your needs.

We provide:

- Certified Quality: All footwear meets relevant safety standards.

- Bulk Supply: Reliable, large-volume manufacturing for distributors and corporate clients.

- Custom Solutions: Options for branding and specific requirements.

Let's equip your team with the perfect footwear for their environment.

Contact us today for a quote and let's discuss your specific requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards