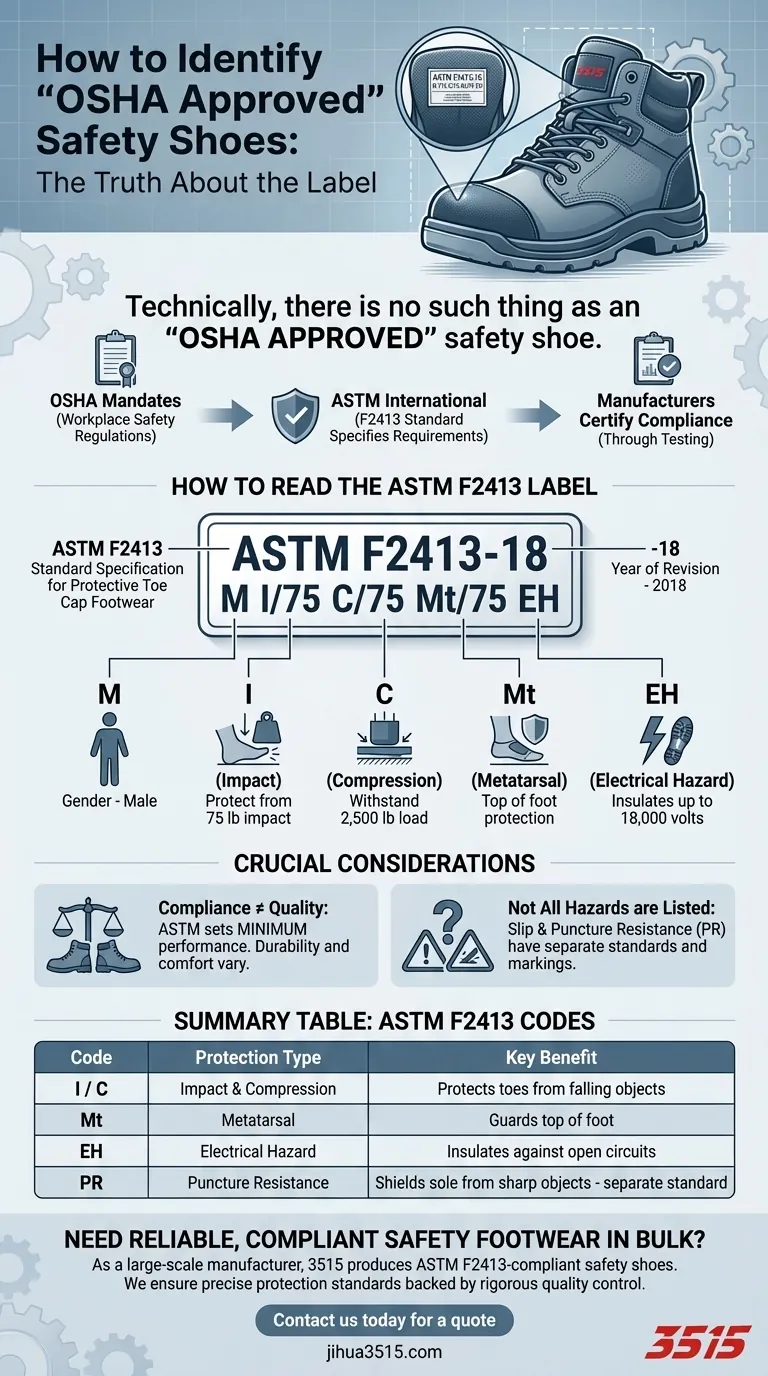

Technically, there is no such thing as an "OSHA approved" safety shoe. Instead, the Occupational Safety and Health Administration (OSHA) requires that protective footwear meets or exceeds the standards set by an organization called ASTM International. To identify a compliant shoe, you must look for a permanent label, typically on the tongue or inside collar, that explicitly references the ASTM F2413 standard and lists the specific types of protection it offers.

The key to verifying compliance is not a brand name or an "OSHA Approved" sticker, but a specific, multi-line code printed inside the shoe. Understanding this code is the only way to confirm a shoe meets the required safety standards for your specific job hazards.

The "OSHA Approved" Misconception

OSHA's role is to set and enforce workplace safety regulations. They define the requirements for personal protective equipment (PPE) but do not test, certify, or "approve" specific products themselves.

OSHA Mandates, ASTM Specifies

OSHA mandates that employers must ensure their employees use protective footwear in hazardous environments. They point to ASTM F2413 as the consensus standard that defines the minimum performance requirements for that footwear.

What the Standard Guarantees

When a shoe is marked as compliant with ASTM F2413, the manufacturer is certifying that it has been tested and meets specific criteria for protection against a variety of workplace dangers.

How to Read the ASTM Label: A Line-by-Line Guide

The compliance label is your definitive guide. It is required to be legible and permanently attached to the footwear. It typically follows a clear, two-line format.

Line 1: The Standard Identification

The first line will always identify the standard itself.

It will read ASTM F2413-18, for example.

- ASTM F2413: This is the designation for the "Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear."

- -18: This number indicates the year the standard was last revised (in this case, 2018). Using footwear that meets the most current version is always the best practice.

Line 2: The Specific Protections

The second line identifies the gender (M/F) the shoe is designed for, followed by the codes for the specific hazards it protects against.

- I (Impact Resistance): This indicates the safety toe can protect against a 75-pound impact.

- C (Compression Resistance): This shows the toe can withstand a compressive load of 2,500 pounds.

- Mt (Metatarsal Protection): This code means the shoe has added protection for the top of the foot (the metatarsal bones) against impact.

- EH (Electrical Hazard): This rating signifies the shoe has non-conductive, shock-resistant soles and heels, protecting the wearer from open circuits of up to 18,000 volts.

Understanding the Limitations

A compliant label is critical, but it's equally important to understand what it doesn't tell you.

Compliance vs. Quality

The ASTM standard sets a minimum performance baseline. Two shoes can have the exact same label, but differ wildly in terms of durability, comfort, and the quality of their materials.

A Label Only Covers What It Lists

If a shoe is only labeled with "I" and "C", it is a compliant safety-toe shoe, but it offers no certified metatarsal or electrical hazard protection. Never assume a shoe protects against a hazard that isn't explicitly listed in its code.

Not All Hazards are on the Label

Other critical safety features, like slip resistance or puncture resistance (PR), are covered by different standards and have their own unique markings. Always verify the shoe meets all the needs of your specific work environment.

Matching the Shoe to Your Specific Hazard

Use the ASTM label to make an informed decision based on the real-world risks you face.

- If your primary focus is protection from falling objects: Ensure the shoe is rated for both I (Impact) and C (Compression).

- If you work with heavy materials that could roll onto your foot: The Mt (Metatarsal) rating provides essential protection beyond the toe cap.

- If you work near live electrical circuits: You must have an EH (Electrical Hazard) rated shoe to insulate you from the ground.

- If you work in sensitive electronic manufacturing: You would need an ESD (Electrostatic Dissipative) shoe, which reduces static buildup, a different rating from EH.

By learning to read these codes, you can confidently select footwear that provides the precise protection required for your work environment.

Summary Table:

| ASTM F2413 Code | Protection Type | Key Benefit |

|---|---|---|

| I / C | Impact & Compression | Protects toes from falling objects (75 lb impact, 2,500 lb compression) |

| Mt | Metatarsal | Guards the top of the foot from impact |

| EH | Electrical Hazard | Insulates against open circuits up to 18,000 volts |

| PR | Puncture Resistance | Shields the sole from sharp objects (separate standard) |

Need reliable, compliant safety footwear in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets the precise protection standards your workforce needs, backed by rigorous quality control for durability and comfort.

Contact us today for a quote and let us help you equip your team with the right protection.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision