The primary advantage of steel toe shoes is their superior ability to protect the wearer from impact and compression hazards. They are engineered to withstand significant force from falling objects or heavy rolling equipment, making them the standard for high-risk industrial environments like construction and manufacturing while often being more affordable than alternatives.

The core function of a steel toe shoe is to provide the highest level of physical protection against crushing and impact forces. While this singular focus on strength comes with trade-offs in weight and comfort, it remains the definitive choice for environments where severe foot injuries are a primary risk.

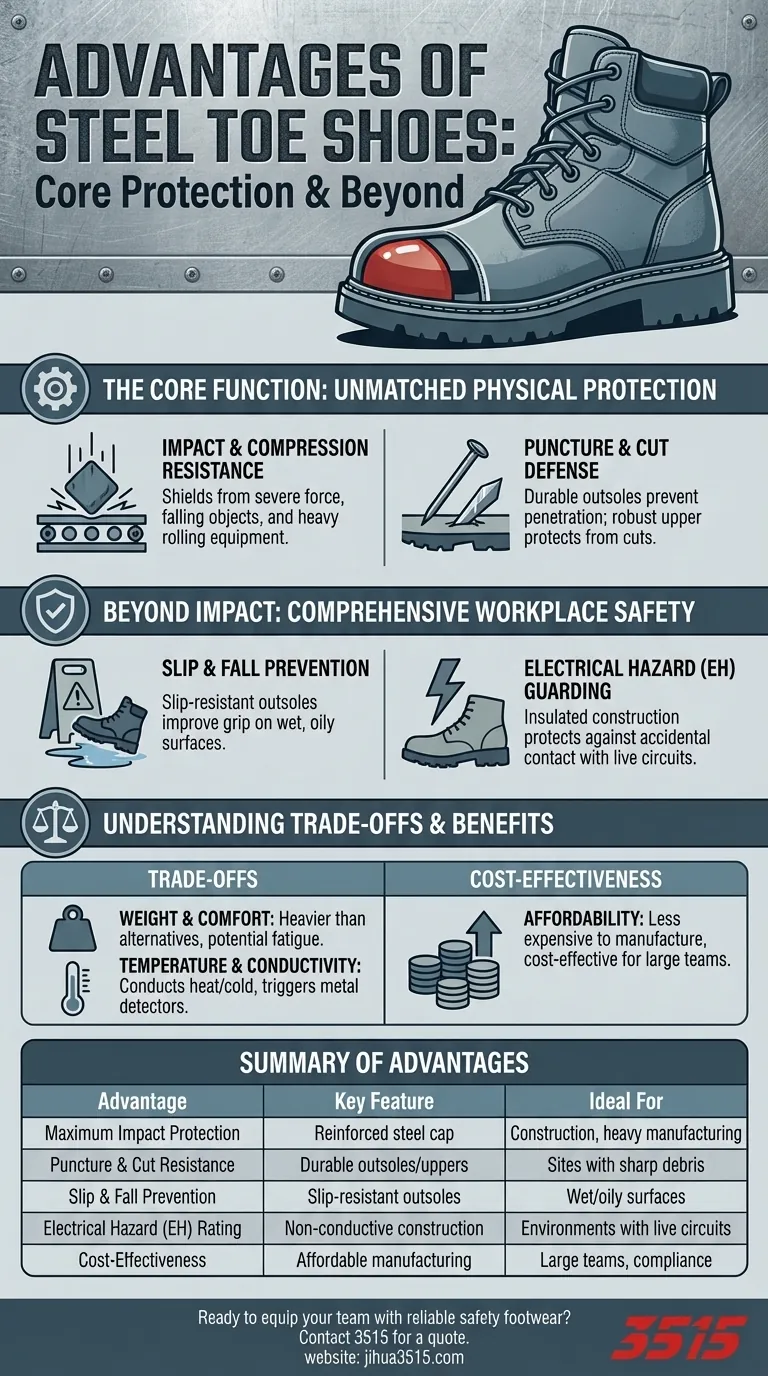

The Core Function: Unmatched Physical Protection

The reputation of steel toe shoes is built on their uncompromising strength. The reinforced steel cap is the central feature that defines their purpose in workplace safety.

Protection from Impact and Compression

A steel toe cap is specifically designed to shield the toes from severe impact, such as a heavy tool falling from a height.

It also provides critical compression resistance, protecting the foot from being crushed by rolling objects or heavy machinery.

Defense Against Punctures and Cuts

Beyond the toe cap, these shoes are constructed with durable outsoles that prevent sharp objects like nails or metal shards from penetrating the bottom of the foot.

The robust materials used in the upper part of the shoe also offer a degree of protection against cutting hazards from machinery or sharp debris.

Beyond Impact: Comprehensive Workplace Safety

While the steel cap is the main feature, a well-designed safety shoe offers a more holistic approach to preventing common workplace injuries.

Slip and Fall Prevention

Most safety footwear, including steel toe models, incorporates slip-resistant outsoles.

This design significantly improves grip on wet, oily, or uneven surfaces, which is a leading cause of workplace accidents.

Guarding Against Electrical Hazards

Though steel is a conductive material, many steel toe shoes are rated for Electrical Hazard (EH) protection.

This is achieved through non-conductive materials in the sole and overall construction, which insulate the wearer from the ground and protect against accidental contact with live electrical circuits.

Understanding the Trade-offs

Choosing steel toe footwear involves a clear understanding of its limitations. Its primary strength—the steel cap—is also the source of its main drawbacks.

Weight and Comfort

Steel toe shoes are noticeably heavier than composite toe or standard footwear. This added weight can lead to fatigue and discomfort during long shifts or jobs that require extensive walking.

Temperature and Conductivity

Steel is an excellent conductor of temperature. In extreme cold, the steel cap can become very cold, and in extreme heat, it can become hot, potentially causing discomfort.

Because they contain metal, they will reliably trigger metal detectors, making them unsuitable for certain secure environments.

Cost-Effectiveness

A significant advantage is affordability. Steel toe shoes are typically less expensive to manufacture than composite toe alternatives, making them a cost-effective choice for outfitting large teams while meeting essential OSHA safety standards.

Making the Right Choice for Your Environment

Selecting the appropriate safety footwear requires matching the shoe's features to the specific hazards of your work environment.

- If your primary focus is maximum impact protection: Steel toe is the definitive standard for heavy industrial, construction, and manufacturing settings where the risk of crushing injuries is high.

- If your primary focus is all-day comfort in a moderate-risk area: The weight of steel toes may be a disadvantage, and lighter composite alternatives might be more suitable.

- If your primary focus is cost-effective safety compliance: Steel toe shoes provide the necessary protection to meet regulatory standards at a more accessible price point.

Ultimately, choosing the right protective equipment is a foundational step in ensuring a safe and productive work environment.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Maximum Impact Protection | Reinforced steel toe cap | Construction, heavy manufacturing |

| Puncture & Cut Resistance | Durable outsoles and uppers | Sites with sharp debris, nails |

| Slip & Fall Prevention | Slip-resistant outsoles | Wet, oily, or uneven surfaces |

| Electrical Hazard (EH) Rating | Non-conductive construction | Environments with live circuits |

| Cost-Effectiveness | Affordable manufacturing | Large teams, budget-conscious compliance |

Ready to equip your team with reliable, high-performance safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and safety boots for distributors, brand owners, and bulk clients. We ensure your workforce has the durable, compliant protection they need.

Contact us today for a quote and discover how we can meet your specific safety footwear requirements.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What does OSHA say about steel toe boots? A Guide to Compliant Footwear

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- How should steel toe boots be maintained for longevity? A Guide to Maximize Safety and Durability

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort

- Are steel toe boots comfortable for casual wear? Find Your Perfect Balance of Style & Safety

- What are the differences between steel toe and composite toe work boots? Choose the Right Safety for Your Job

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- How can leather conditioner improve steel toe boot comfort? Soften Stiff Leather for a Better Fit