Common examples of slip-resistant shoes range from occupational footwear like chef clogs, hospital shoes, and server shoes to more general styles like work boots and certain athletic sneakers. While these styles are frequently designed for traction, the label "slip-resistant" is not about the shoe's category but about its specific engineering—particularly the material and pattern of its sole.

The true measure of a slip-resistant shoe is not its style, but its technical design. Effective traction comes from a specific combination of a high-grade rubber sole, a tread pattern engineered to channel away liquids, and often, a formal safety certification.

What Truly Defines a Slip-Resistant Shoe?

A shoe's ability to prevent slips on wet or oily surfaces is a result of intentional engineering. Understanding these core components allows you to look past marketing claims and identify genuinely effective footwear.

The Critical Role of the Sole Material

The foundation of any slip-resistant shoe is its outsole. These are typically made from high-grade, soft rubber or specialized synthetic compounds that are formulated to create high friction against a surface.

Unlike the harder, less-grippy plastics found on many standard shoes, this material remains pliable and can better conform to microscopic surface imperfections, maximizing grip.

The Science of Tread Patterns

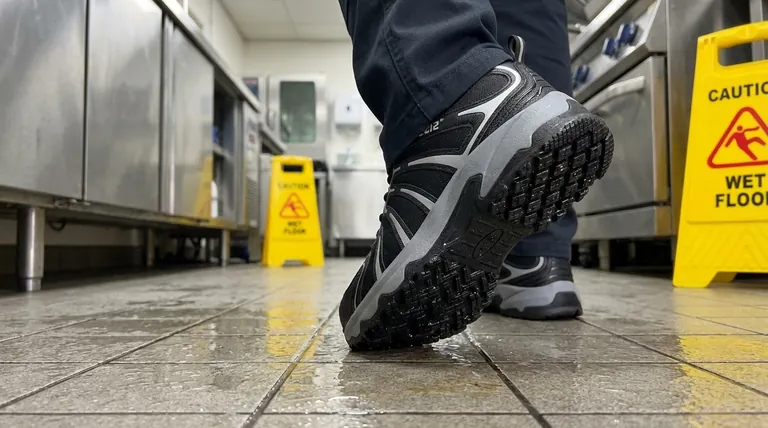

The design of the tread is just as important as the material. Effective slip-resistant shoes feature intricate, specialized tread patterns, often using interlocking hexagons or circles.

These patterns are not for style; they create tiny channels that siphon liquids like water and oil away from the shoe's contact points. This prevents a film of liquid from forming underfoot (hydroplaning) and allows the rubber sole to make direct, solid contact with the floor.

Beyond the Sole: Durable Construction

True slip-resistant shoes are typically built as safety footwear. They feature thick, durable construction and are made from reinforced materials designed to withstand the rigors of a demanding work environment.

Many also include water-resistant uppers and reinforced toes, distinguishing them from everyday shoes that prioritize flexibility or fashion over resilience and protection.

How to Verify Slip-Resistant Claims

Relying solely on a product's name is a common mistake. True verification requires looking for objective proof of performance.

Look for Official Certification

The most reliable indicator of performance is a third-party certification. In the United States and Canada, look for shoes that explicitly state they meet or exceed ASTM F-2913 standards.

This certification confirms the shoe has been scientifically tested on various slick surfaces and achieved a required coefficient of friction (a measure of grip), ensuring it performs as a true piece of safety equipment.

Inspecting the Shoe Yourself

When a certification isn't listed, you can perform a visual inspection. Check the product description for terms like "slip-resistant rubber outsole".

Examine the sole itself. Look for a soft, pliable rubber material and a tread pattern with small, deep, and intricate grooves designed to grip and channel fluid, not just large, simple lugs meant for dirt.

Common Pitfalls to Avoid

Navigating the market for slip-resistant shoes requires a discerning eye. Being aware of potential shortcomings ensures you get the protection you need.

Not All "Non-Slip" Labels are Equal

The term "non-slip" is often used in marketing without being backed by official testing. A shoe designed for "traction" on a basketball court is not the same as one engineered for an oily kitchen floor.

Always prioritize shoes that cite specific safety standards over those with vague marketing claims.

Durability vs. Day-to-Day Comfort

The robust construction that makes a slip-resistant shoe safe and durable can sometimes mean it is heavier or less flexible than a standard casual shoe. The primary focus is occupational safety, which can involve a trade-off with the lightweight comfort of fashion footwear.

Making the Right Choice for Your Needs

Your ideal shoe depends entirely on the environment where you need protection.

- If your primary focus is professional safety (e.g., kitchen, hospital): Prioritize shoes with explicit ASTM F-2913 certification and a deep, liquid-channeling tread pattern.

- If your primary focus is casual daily wear with some risk: Look for athletic or casual shoes with high-grade soft rubber soles and intricate tread, even if they lack formal certification.

- If your primary focus is outdoor or rugged terrain: Select work boots with deep, aggressive lugs designed for uneven surfaces, ensuring they are also rated for wet conditions.

An effective slip-resistant shoe is a piece of engineered safety equipment, so choose it based on its technical specifications, not just its name.

Summary Table:

| Feature | Key Takeaway |

|---|---|

| Sole Material | High-grade, soft rubber for maximum friction. |

| Tread Pattern | Intricate designs (e.g., hexagons) to channel liquids. |

| Certification | Look for ASTM F-2913 standards for verified safety. |

| Durability | Reinforced construction for demanding work environments. |

Need reliable, certified slip-resistant footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, engineered with the precise materials and tread patterns detailed in this article to ensure maximum protection and durability.

We can help you:

- Source or customize ASTM F-2913 certified footwear.

- Develop private-label safety shoes tailored to your market.

- Fulfill large-volume orders with consistent quality.

Let's discuss your specific needs. Contact our team today to request a quote or learn more about our manufacturing solutions.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How can one verify if shoes are truly slip-resistant? Look for the ASTM Certification Mark

- How can footwear reduce slip, trip, and fall risks? Match Your Shoes to the Hazard

- How do men's work shoes provide protection from electrical hazards? Insulate Yourself from Live Circuits

- What are the benefits of breathable materials in work shoes? Enhance Comfort & Health for Your Workforce

- What role do ankle straps play in preventing slips? Secure Your Stride with Internal Stability

- What is the cost-benefit analysis of investing in quality slip resistant shoes? A Smart Investment for Safety & Savings

- What combination of features prevents non-slip shoes from slipping? The Science of Sole Material, Tread, and Liquid Displacement

- What are the main components of a slip-resistant shoe? Unpacking the Anatomy of Workplace Safety