At its core, a safety shoe is a critical piece of Personal Protective Equipment (PPE) designed to prevent debilitating foot injuries in hazardous work environments. They are not merely durable footwear; they are engineered systems that shield against specific threats ranging from falling objects and sharp punctures to electrical shocks and slippery surfaces. The importance of wearing them is rooted in their proven ability to drastically reduce the risk of workplace accidents.

The true value of safety footwear is not in its existence, but in its correct application. Understanding that "safety shoe" is a broad category is the first step. True workplace safety comes from precisely matching the shoe's certified protection level and features to the specific, identified hazards of your work environment.

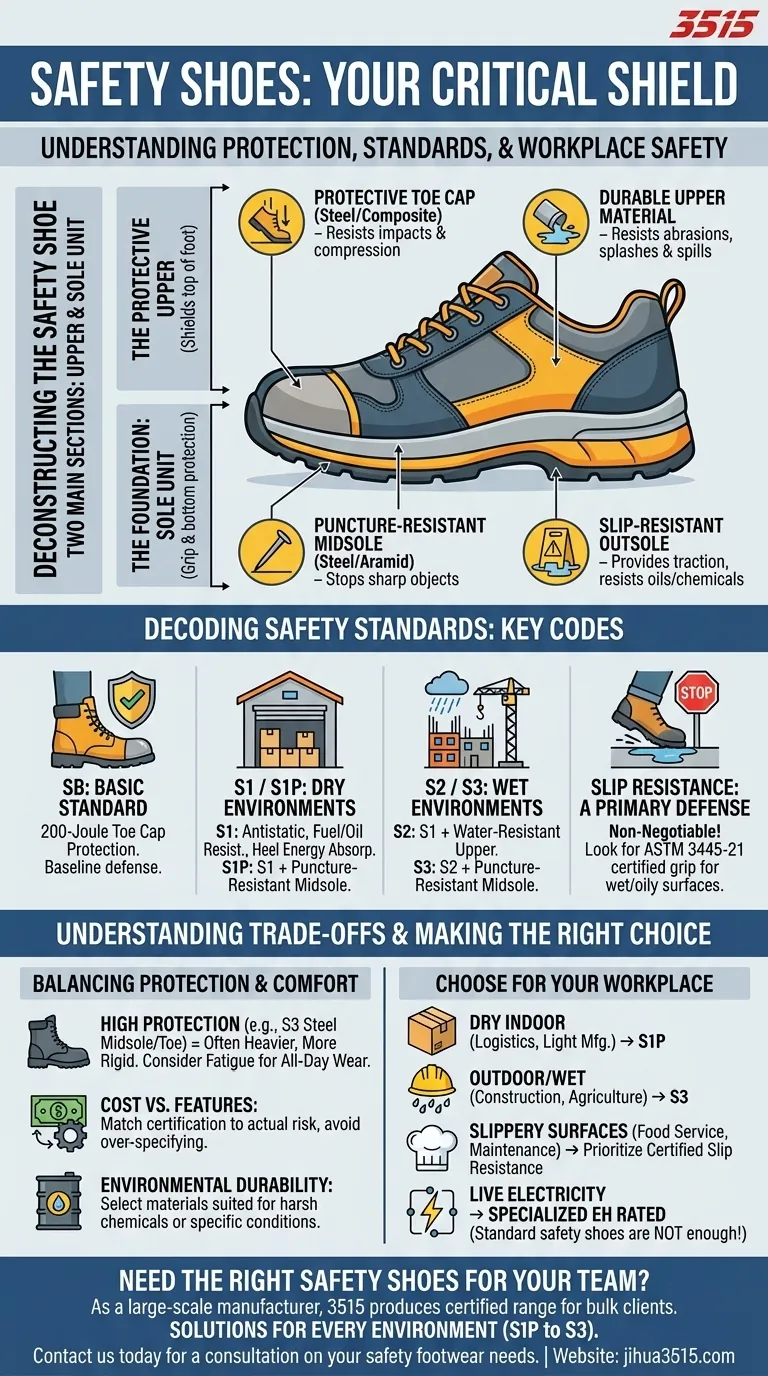

Deconstructing the Safety Shoe: More Than Just a Steel Toe

A safety shoe is a complex system with two main sections: the upper, which protects the top of the foot, and the sole unit, which protects the bottom. Each component serves a distinct protective function.

The Protective Upper

The upper part of the shoe shields against impacts, splashes, and compression. Key elements include the protective toe cap (often steel or composite), the primary defense against falling objects, and the durable upper material, which resists abrasions and spills.

The Foundation of Safety: The Sole Unit

The sole unit is the shoe's foundation, providing grip and protecting against hazards from below. It consists of the outsole, which provides traction and resists oil or chemicals, and often a puncture-resistant midsole to stop sharp objects like nails from piercing through.

Decoding the Safety Standards: What the Codes Mean

Safety shoes are rated according to standardized codes that certify their specific protective capabilities. Understanding these codes is essential for selecting the appropriate footwear.

SB - The Basic Standard

SB (Safety Basic) is the baseline standard for safety footwear. Any shoe with this rating includes a protective toe cap tested to withstand a 200-joule impact.

S1 & S1P - Protection for Dry Environments

An S1 shoe includes all the features of SB, but adds antistatic properties, fuel oil resistance, and energy absorption in the heel.

The S1P rating includes all S1 features plus a puncture-resistant midsole. This is a common standard for indoor work where sharp floor debris is a risk.

S2 & S3 - Protection for Wet Environments

An S2 shoe has all the features of S1, with the critical addition of a water-resistant upper. This makes it suitable for work in damp or wet conditions.

The S3 rating is one of the most comprehensive. It combines all the features of an S2 shoe (including water resistance) with the puncture-resistant midsole of an S1P.

The Critical Factor of Slip Resistance

While impact and puncture protection are vital, one of the most common workplace injuries stems from slips, trips, and falls. Modern safety standards place a heavy emphasis on certified grip.

Why Grip is Non-Negotiable

Slips are a leading cause of preventable accidents. A shoe's outsole design and material composition are engineered to maintain traction on wet, oily, or uneven surfaces, making this a primary safety feature.

Understanding the Standards

Newer standards, such as ASTM 3445-21, provide a universal benchmark for testing and certifying a shoe's slip resistance. Looking for this certification ensures the footwear has been rigorously tested for performance on slippery surfaces.

Understanding the Trade-offs

No single safety shoe is perfect for every task. Selecting the right one involves balancing protection levels with the practical realities of the job.

Protection vs. Comfort and Fatigue

Generally, a higher level of protection (like an S3 rating with a steel midsole and toe cap) results in a heavier, more rigid shoe. For workers on their feet all day, this can lead to fatigue, so it's critical to match the protection level to the actual risk.

Cost vs. Required Features

It is unnecessary to equip every worker with the highest-rated and most expensive shoe available. A risk assessment should determine the necessary features, preventing over-specifying and ensuring resources are used efficiently.

Environment-Specific Durability

A shoe's material must be suited to its environment. Footwear used in an environment with harsh chemicals requires different materials than a shoe designed for a construction site or a warehouse floor to ensure its protective features do not degrade.

Making the Right Choice for Your Environment

Your specific workplace hazards should be the ultimate guide in your selection process.

- If you work in a dry, indoor environment (e.g., logistics, light manufacturing): An S1P-rated shoe provides the necessary impact, antistatic, and puncture protection.

- If you work in outdoor or frequently wet conditions (e.g., construction, agriculture): An S3-rated shoe is essential for its combination of water resistance and full protective features.

- If your primary hazard is slippery surfaces (e.g., food service, maintenance): Prioritize footwear explicitly certified for high slip resistance under a recognized standard.

- If you work around live electricity: You must seek out specialized Electrical Hazard (EH) rated footwear, as standard safety shoes may not provide adequate protection.

Ultimately, selecting the correct safety footwear is a foundational investment in a resilient and proactive safety culture.

Summary Table:

| Feature | Key Protection | Common Standards |

|---|---|---|

| Toe Cap | Protects from falling objects | SB (Basic), S1, S1P, S2, S3 |

| Midsole | Prevents punctures from sharp objects | S1P, S3 |

| Upper Material | Resists water, chemicals, abrasions | S2 (water-resistant), S3 |

| Outsole | Provides slip resistance on oily/wet surfaces | ASTM 3445-21 certified |

| Electrical Hazard | Protects against live electrical circuits | EH-rated footwear |

Need the right safety shoes for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We offer solutions for every work environment—from S1P for indoor logistics to S3 for wet outdoor conditions—ensuring your workforce is protected without compromising on comfort or durability.

Contact us today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- How does the weight of composite toe boots compare to their protection level? A Guide to Lighter, Safer Footwear

- What type of work shoes benefit individuals with high arches? Find Support for Long-Hour Comfort

- Why is outsole traction critical for safety shoes in urban low light? Secure Grip for Unseen Hazards

- Why is the provision of standardized protective footwear necessary for poultry farm visitors? Essential Biosecurity Guide

- What core protective functions do Industrial-grade Safety Shoes provide? Key Foot Protection for High-Risk Environments

- What are the new requirements for puncture resistance? Understand P, PL, and PS Ratings

- How does a wide forefoot outsole design contribute to stability? Unlock Superior Balance in Safety Footwear

- Why are industrial-grade safety shoes essential for thermal power plants? Protect Your Team From High-Heat & Impact Risks