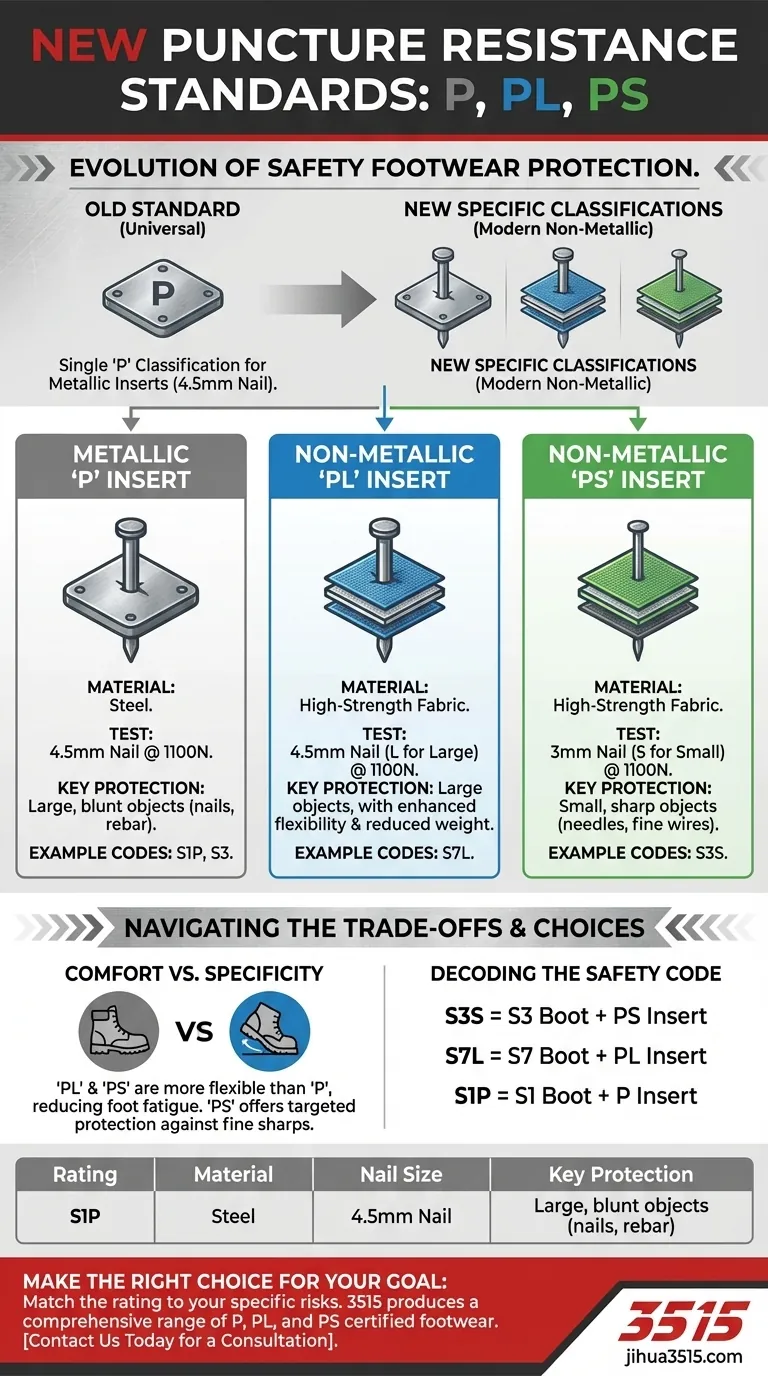

The requirements for puncture resistance in safety footwear have become more specific, moving beyond a single classification. The old, universal 'P' marking is now supplemented by new codes—'PL' and 'PS'—which define protection against different types of puncture risks, primarily for non-metallic inserts. These changes are based on standardized tests using either a 4.5mm or a 3mm nail at a force of 1100N.

The core change in puncture resistance standards is the introduction of specific tests for modern, non-metallic inserts. This allows you to choose footwear precisely matched to the risks of your work environment, whether from large construction nails or smaller, sharper objects.

From a Single Standard to Specific Classifications

The evolution of these standards reflects advancements in material technology and a deeper understanding of workplace hazards. The goal is to provide clearer, more accurate protection ratings.

The Original 'P' Marking

The traditional 'P' marking has long signified a puncture-resistant sole, typically made of steel. The test for this metallic insert remains unchanged, utilizing a 4.5mm nail. Footwear with this protection will be marked with codes like S1P or S3.

The Rise of Non-Metallic Inserts

Modern safety footwear often uses non-metallic inserts, made from materials like high-strength ballistic fabrics. These offer significant advantages in flexibility, weight, and thermal insulation compared to steel. This innovation required a more nuanced testing approach.

Introducing 'PL' and 'PS' for Precision

To address the performance of non-metallic inserts, two new classifications were created, both tested at a force of 1100 Newtons.

- PL: Indicates perforation resistance tested with a Large 4.5mm nail. This offers protection equivalent to traditional steel plates against larger hazards.

- PS: Indicates perforation resistance tested with a Small 3mm nail. This standard is designed for environments where risks come from smaller, sharper objects like needles or fine wires.

Understanding the Practical Difference

The distinction between P, PL, and PS is not just about the material; it's about the specific type of threat each is designed to stop.

Metallic 'P' Inserts

These steel plates offer maximum resistance to perforation from large, blunt objects like construction nails or rebar. They are rigid, reliable, and a long-standing industry standard.

Non-Metallic 'PL' Inserts

A 'PL' rated sole provides protection against the same size of object as a steel plate (a 4.5mm nail). However, its fabric-like construction makes the footwear lighter, more flexible, and more comfortable for all-day wear.

Non-Metallic 'PS' Inserts

The 'PS' rating is a critical addition for specific industries. It certifies protection against much smaller and sharper hazards that could potentially slip through the weave of a standard non-metallic insert. This is vital for sectors like waste management or emergency services.

Navigating the Trade-offs

Choosing the right footwear requires understanding the balance between different features. No single type is universally "best."

Hazard Specificity

The key trade-off is between general and specific protection. A 'PS' rating ensures protection against fine sharps, which is a specialized need. A 'P' or 'PL' rating is designed for the more common, larger puncture hazards found on construction sites.

Comfort and Flexibility

Non-metallic inserts (PL and PS) are significantly more flexible than steel (P), reducing foot fatigue. For workers who are constantly kneeling, climbing, or walking long distances, this can be a major factor in overall safety and well-being.

Decoding the Full Safety Code

These puncture ratings are combined with the overall safety standard of the footwear. You will see them as part of a larger code, such as S3S or S7L.

S3S: A high-spec safety boot (S3) with a non-metallic insert tested against a Small nail (S).S7L: A high-spec waterproof safety boot (S7) with a non-metallic insert tested against a Large nail (L).S1P: A basic safety boot (S1) with a traditional metallic Puncture plate (P).

Making the Right Choice for Your Goal

Select your footwear based on a clear assessment of your daily work environment.

- If your primary risk is from construction debris like large nails or rebar: Your safest options are boots rated P (metallic) or PL (non-metallic).

- If you need a versatile boot with enhanced comfort and flexibility for general hazards: A PL rated boot provides an excellent modern balance of protection and wearability.

- If your work involves potential contact with fine, sharp objects like needles, tacks, or metal shavings: You should exclusively choose boots with the PS rating for targeted protection.

Matching your footwear's specific puncture rating to your environment's specific risks is the most effective way to ensure your safety.

Summary Table:

| Rating | Material Type | Nail Size | Key Protection |

|---|---|---|---|

| P | Metallic (Steel) | 4.5mm | Large, blunt objects (nails, rebar) |

| PL | Non-Metallic | 4.5mm | Large objects, with enhanced flexibility |

| PS | Non-Metallic | 3.0mm | Small, sharp objects (needles, fine wires) |

Ensure your team has the right protection for their specific hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear (including P, PL, and PS rated boots) for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise combination of protection, comfort, and durability your workforce needs.

Contact us today for a consultation and let us help you equip your team with the best safety footwear.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- What is the function of impact-resistant toe caps in safety footwear? Protect Your Feet During Heavy Lifting