The defining characteristic of composite toe boots is their ability to provide certified impact protection at a significantly lower weight than traditional steel toe boots. By using materials like carbon fiber, fiberglass, and advanced plastics, they meet mandated safety standards while drastically reducing the fatigue and strain on the wearer over a long workday.

The core trade-off is simple: composite toe boots offer a superior balance of comfort and certified safety for most work environments, while steel toe boots provide a higher absolute maximum of impact resistance at the cost of greater weight and less comfort.

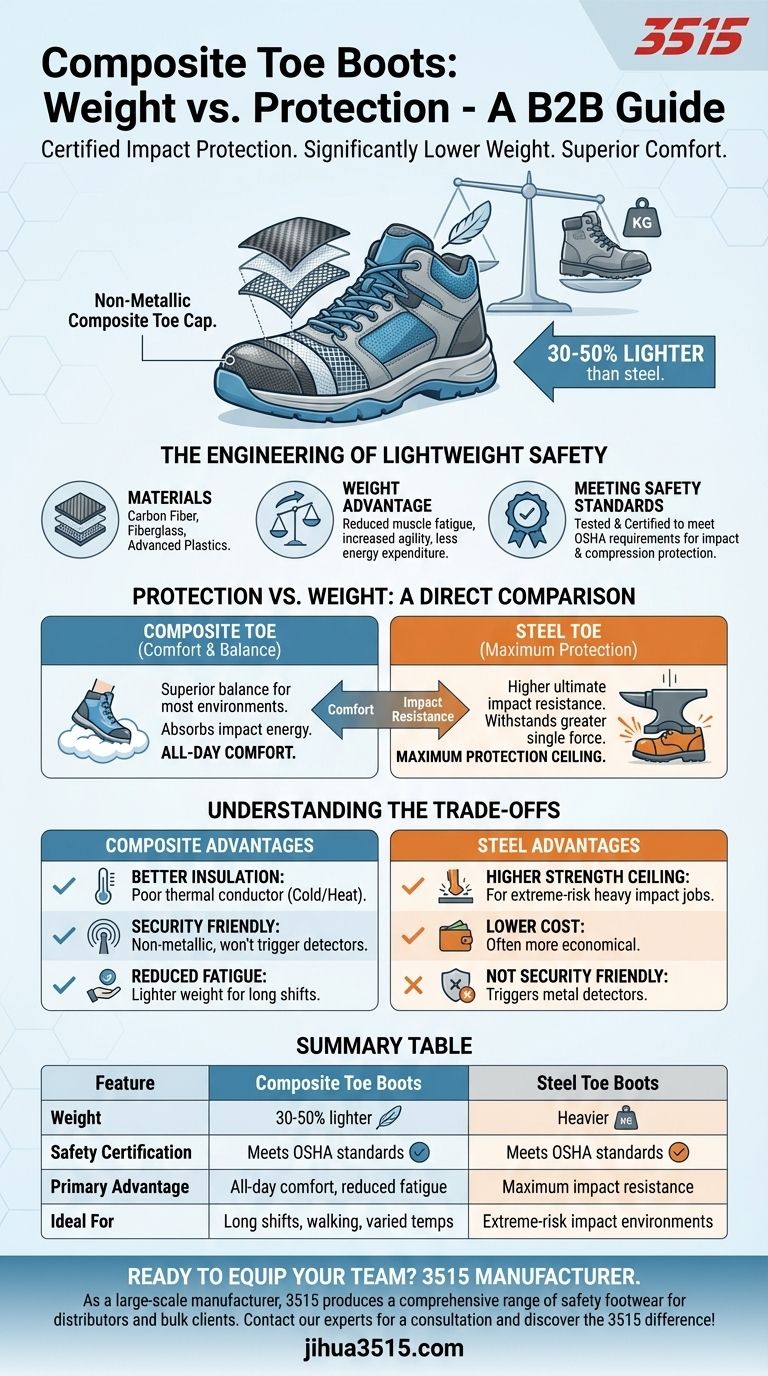

The Engineering of Lightweight Safety

To understand the relationship between weight and protection, you must first understand the materials and design philosophy behind composite toe boots.

The Materials Used

Composite safety toes are constructed from a blend of non-metallic materials. These typically include carbon fiber, fiberglass, and specialized plastics.

This material choice is the primary reason for their lightweight nature.

The Weight Advantage

Composite toe caps are generally 30-50% lighter than their steel counterparts. This reduction in weight has a direct and significant impact on wearer performance.

Lighter footwear leads to increased agility and a measurable reduction in muscle fatigue over the course of a shift.

Meeting Official Safety Standards

Despite being lighter, composite toe boots are engineered to meet the same OSHA (Occupational Safety and Health Administration) safety requirements as steel toe boots.

This means they have been tested and certified to provide a specific, standardized level of protection against both impact and compression. The protection level is not compromised for the sake of weight.

Protection vs. Weight: A Direct Comparison

The choice between composite and steel often comes down to weighing the benefits of comfort against the demands of a specific work environment.

Impact Resistance

While both types meet the required safety standards, steel offers a higher ultimate impact resistance. It can withstand a greater single force before catastrophic failure.

Composite toes absorb impact by dispersing the energy. They provide sufficient protection for the vast majority of workplace hazards.

All-Day Comfort and Fatigue

The weight difference is the single biggest factor in long-term comfort. The lighter composite boot reduces the energy a worker must expend with every step.

This is the primary reason wearers who spend long hours on their feet or walk long distances often prefer composite toe boots.

Understanding the Trade-offs

Choosing the right boot requires an objective look at the advantages and disadvantages inherent in the design of composite toes.

The Upper Limit of Protection

For jobs with an exceptionally high risk of severe impact from heavy falling objects, the higher strength ceiling of steel may be the more prudent choice.

Composite toes provide certified protection, but steel provides more of it.

Environmental Advantages

Composite materials are poor thermal conductors. This means they provide better insulation against both extreme cold and heat compared to steel.

Because they contain no metal, composite toe boots do not set off metal detectors, making them ideal for high-security environments like airports or certain government facilities.

Making the Right Choice for Your Goal

Your specific work environment and daily tasks should dictate your choice.

- If your primary focus is maximum impact protection: Steel toe boots offer the highest possible level of resistance for extreme-risk jobs.

- If your primary focus is all-day comfort and reduced fatigue: Composite toes are significantly lighter, making them the superior choice for long hours on your feet.

- If you work in environments with extreme temperatures or metal detectors: The non-conductive and non-metallic properties of composite toes provide a decisive advantage.

Ultimately, choosing the right safety boot is about matching the tool to the specific demands of your job.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Weight | 30-50% lighter | Heavier |

| Safety Certification | Meets OSHA standards | Meets OSHA standards |

| Primary Advantage | All-day comfort, reduced fatigue | Maximum impact resistance |

| Ideal For | Long shifts, walking, varied temperatures | Extreme-risk impact environments |

Ready to equip your team with the perfect balance of safety and comfort?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite and steel toe boots, ensuring you get the right protection for your specific job demands.

Let us help you enhance worker comfort and productivity. Contact our experts today for a consultation and discover the 3515 difference!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why is the automated detection of foot protection equipment valuable? Optimize Compliance and Drive Sales Growth

- What are the biomechanical advantages of integrating sensors into shoes vs wrist-worn devices? Precision Fall Detection

- Why are flexible piezoresistive pressure sensors integrated into smart footwear systems for the prevention of diabetic foot ulcers?

- What are the key features of safety shoe soles? A Complete Guide to Workplace Foot Protection

- What are the two main materials compared for protective footwear? PVC vs. Rubber for Your Work Hazards

- How do slip resistant safety shoes differ from non-slip rated shoes? Cut Through the Marketing Jargon

- What are some common protections offered by modern safety boots? Find the Right PPE for Your Workplace

- How do composite safety shoes react to impact compared to steel toed shoes? A Guide to Choosing the Right Protection