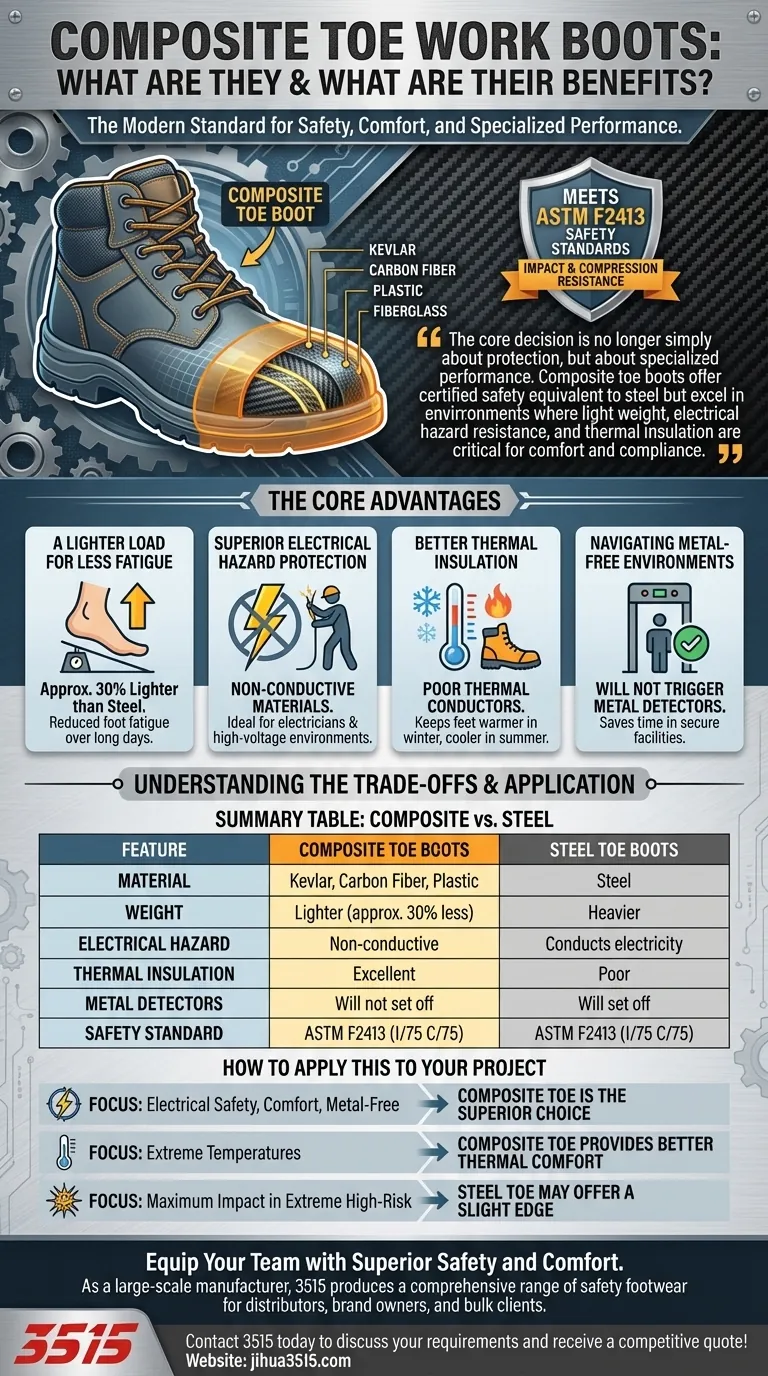

Composite toe work boots are a modern category of safety footwear featuring a protective toe cap made from non-metallic materials like Kevlar, carbon fiber, plastic, or fiberglass. Their primary benefits are that they are significantly lighter than traditional steel toe boots, do not conduct electricity or heat, and will not set off metal detectors, all while meeting the same official ASTM safety standards for impact and compression resistance.

The core decision is no longer simply about protection, but about specialized performance. Composite toe boots offer certified safety equivalent to steel but excel in environments where light weight, electrical hazard resistance, and thermal insulation are critical for comfort and compliance.

What Defines a Composite Toe Boot?

Understanding what makes a composite toe boot distinct from its steel counterpart comes down to its material composition and how it achieves its safety rating.

The Non-Metallic Materials

The term "composite" refers to the blend of materials used in the toe cap. Instead of a solid piece of steel, these caps are crafted from advanced, rugged materials.

This includes Kevlar, a high-strength aramid fiber; carbon fiber, known for its strength-to-weight ratio; and other specialized plastics and fiberglass. The key unifying feature is that they are entirely metal-free.

Meeting the Safety Standard

Critically, composite toe boots are engineered to meet the same stringent safety requirements as steel toe boots.

They are tested and certified under the ASTM F2413 standard, which specifies minimum performance requirements for impact and compression resistance. This ensures they provide the necessary protection against common workplace hazards like falling objects and crushing forces.

The Core Advantages Explained

Choosing a composite toe boot provides several distinct, practical advantages over steel, directly impacting your comfort and safety in specific work environments.

A Lighter Load for Less Fatigue

Composite toe caps are roughly 30% lighter than steel ones. While this may seem minor, the weight difference significantly reduces foot fatigue over a long workday, especially for workers who are constantly on their feet or walk long distances.

Superior Electrical Hazard Protection

Because they contain no metal, composite materials do not conduct electricity. This makes them the preferred choice for electricians, engineers, and anyone working in environments where contact with live electrical circuits is a risk.

Better Thermal Insulation

Metal is an excellent conductor of temperature, meaning steel toe boots can become uncomfortably cold in winter and hot in summer. Composite materials are poor thermal conductors, providing much better insulation against extreme temperatures and keeping your feet more comfortable year-round.

Navigating Metal-Free Environments

The non-metallic construction is a major benefit for workers in secure facilities or job sites that require passing through metal detectors. Composite toe boots will not trigger security screening, saving time and hassle.

Understanding the Trade-offs

While composite toe boots offer compelling benefits, an objective assessment requires acknowledging their limitations compared to steel.

Impact Resistance Beyond the Standard

Both steel and composite toe boots must pass the same ASTM I/75 C/75 standard. However, once that standard is met, steel can often withstand a greater impact or compression force before catastrophic failure. For extreme-risk environments with exceptionally heavy materials, steel may offer a higher ultimate breaking point.

Size and Bulk

To achieve the same level of certified protection, a composite toe cap must be thicker and bulkier than a steel one. This can result in a slightly larger, more bulbous toe box on the boot, which may affect fit and aesthetics for some users.

How to Apply This to Your Project

Your choice should be guided by the specific demands and hazards of your daily work environment.

- If your primary focus is electrical safety, all-day comfort, or passing through metal detectors: Composite toe is the clear and superior choice.

- If you work in extreme hot or cold temperatures: Composite toe will provide significantly better thermal comfort and protection.

- If your primary focus is maximum possible impact protection in a high-risk environment (e.g., heavy manufacturing or logging): Steel toe may offer a slight edge for impacts that exceed standard safety ratings.

Ultimately, choosing the right safety toe is about matching the material's specific advantages to the unique demands of your job.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Material | Kevlar, Carbon Fiber, Plastic | Steel |

| Weight | Lighter (approx. 30% less) | Heavier |

| Electrical Hazard | Non-conductive | Conducts electricity |

| Thermal Insulation | Excellent (good for extreme temps) | Poor (conducts heat/cold) |

| Metal Detectors | Will not set off | Will set off |

| Safety Standard | ASTM F2413 (I/75 C/75) | ASTM F2413 (I/75 C/75) |

Equip Your Team with Superior Safety and Comfort

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of composite toe and steel toe boots, ensuring your workforce has the right protection for their specific job hazards.

We provide certified safety, enhanced comfort, and durable performance tailored to your needs.

Contact 3515 today to discuss your work boot requirements and receive a competitive quote!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What role do steel-toe safety shoes play in high-rise construction? Essential PPE for Vertical Build Security

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety