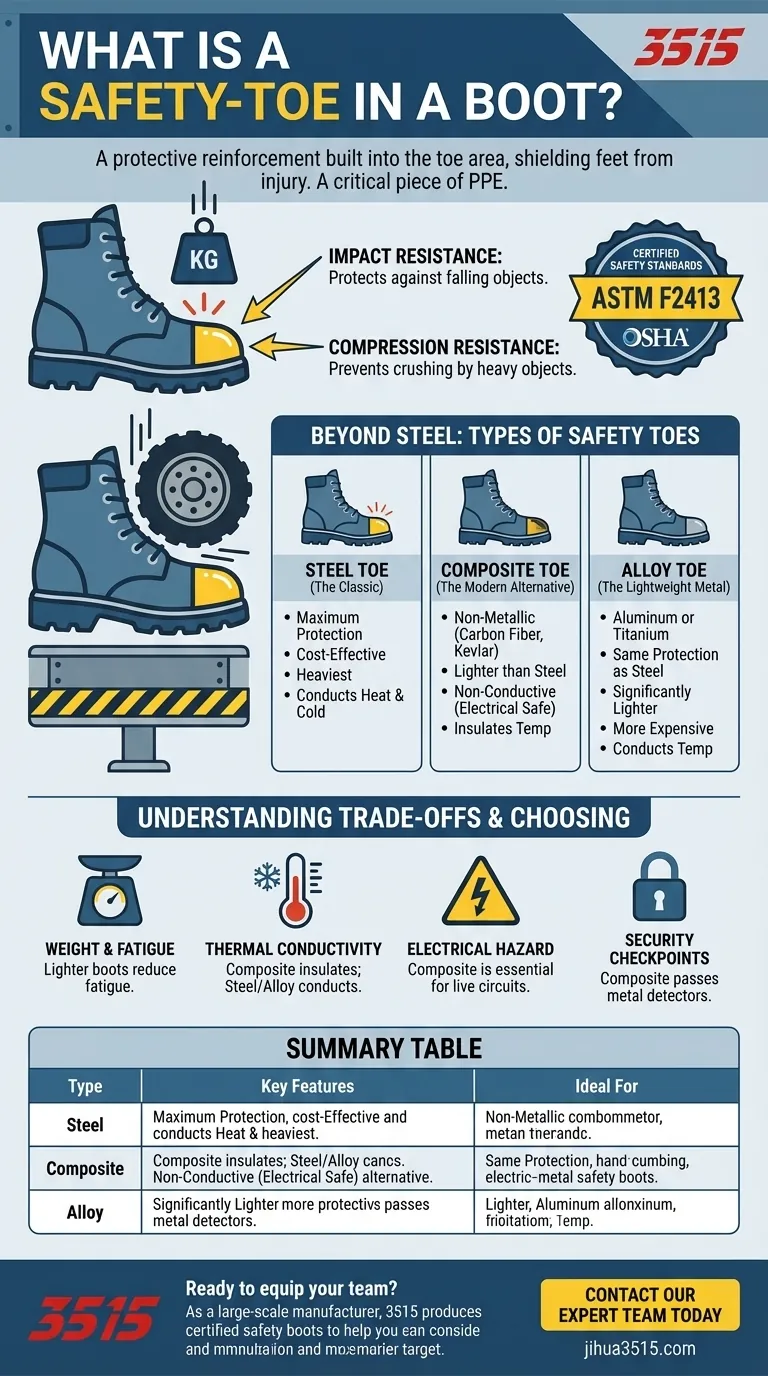

In simple terms, a safety-toe is a protective reinforcement built into the toe area of a boot or shoe. Its primary purpose is to shield your feet from serious injury caused by falling objects or compression, making it a critical piece of personal protective equipment (PPE) in many work environments.

The safety-toe transforms a standard boot into a crucial safety device. While most people think of "steel toes," the specific material used—be it steel, composite, or alloy—creates important trade-offs in weight, environmental protection, and overall comfort.

The Core Function: Protecting Against Workplace Hazards

A safety-toe is engineered and tested to defend against two primary types of physical threats commonly found on job sites. These protections are governed by strict industry standards.

Impact Resistance

The most commonly understood function is protecting the foot from falling objects. A certified safety-toe is designed to withstand a significant amount of force from a direct, heavy impact, such as a dropped tool or piece of building material.

Compression Resistance

This protects your toes from being crushed by heavy rolling or stationary objects. The reinforced cap prevents the boot from collapsing under extreme weight, such as if a vehicle or heavy cart were to roll over the foot.

Meeting Certified Safety Standards

A true safety-toe isn't just a piece of hard material; it's a component that has been tested to meet specific performance standards. In the United States, this is typically the ASTM F2413 standard, which is enforced by the Occupational Safety and Health Administration (OSHA).

This certification ensures the toe cap can withstand specific levels of impact and compression, giving you verified protection.

Beyond Steel: Types of Safety Toes

While "steel-toe" is often used as a generic term, modern safety boots utilize several different materials, each with unique properties.

Steel Toes (The Classic)

This is the traditional standard for safety footwear. Steel provides maximum protection and is often the most cost-effective option. However, it is also the heaviest and can conduct heat and cold.

Composite Toes (The Modern Alternative)

Made from non-metallic materials like carbon fiber, plastic, or Kevlar, composite toes are much lighter than steel. They do not conduct electricity, heat, or cold, making them ideal for electricians or those working in extreme temperatures.

Alloy Toes (The Lightweight Metal)

Typically made from materials like aluminum or titanium, alloy toes provide the same level of protection as steel but at a significantly lower weight. They offer a great balance but are often more expensive than steel.

Understanding the Trade-offs

Choosing the right safety-toe material involves more than just protection; it's about matching the boot to your specific work environment and daily needs.

Weight and Fatigue

Over a long shift, the weight difference between a steel toe and a lighter composite or alloy toe can be significant. Lighter boots can reduce foot fatigue and increase overall comfort.

Thermal Conductivity

Steel and alloy are excellent conductors of temperature. In very cold environments, they can make your feet feel colder, while composite toes provide insulation against both heat and cold.

Electrical Hazard Protection

For anyone working around live electrical circuits, a non-metallic composite toe is essential. Steel and alloy toes can conduct electricity, posing a serious risk in these situations.

Security Checkpoints

A practical consideration is that metal safety toes (steel and alloy) will set off metal detectors. A composite toe boot allows for easier passage through security screenings at airports or secure facilities.

How to Choose the Right Safety Toe

Selecting the correct boot is a critical investment in your personal safety and comfort. Your choice should be based directly on your job's specific demands.

- If your primary focus is maximum protection in a heavy-duty construction or manufacturing environment: A traditional steel toe often provides the most robust and cost-effective solution.

- If your primary focus is working around electrical hazards, in extreme temperatures, or you need to pass through metal detectors frequently: A composite toe is the safest and most practical choice.

- If your primary focus is reducing foot fatigue while still having metallic protection: An alloy toe offers a premium, lightweight alternative to steel.

Ultimately, understanding the differences between safety-toe types allows you to select footwear that actively works to keep you safe and comfortable on the job.

Summary Table:

| Type of Safety Toe | Key Features | Ideal For |

|---|---|---|

| Steel Toe | Maximum protection, cost-effective, conducts temperature | Heavy-duty construction, manufacturing |

| Composite Toe | Lightweight, non-metallic, insulates against heat/cold, electrical hazard safe | Electricians, extreme temperatures, security checkpoints |

| Alloy Toe | Lightweight metal, same protection as steel, premium option | Reducing foot fatigue while maintaining metallic protection |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of steel toe, composite toe, and alloy toe boots, ensuring your workforce has the precise protection and comfort they need.

Contact our expert team today to discuss your requirements and discover how we can provide durable, reliable footwear solutions for your business.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the ASTM standard for puncture resistance? A Guide to Selecting the Right Protective Footwear

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- What are the impact ratings for SAFETY TOE tactical work boots? Essential Protection Explained

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries