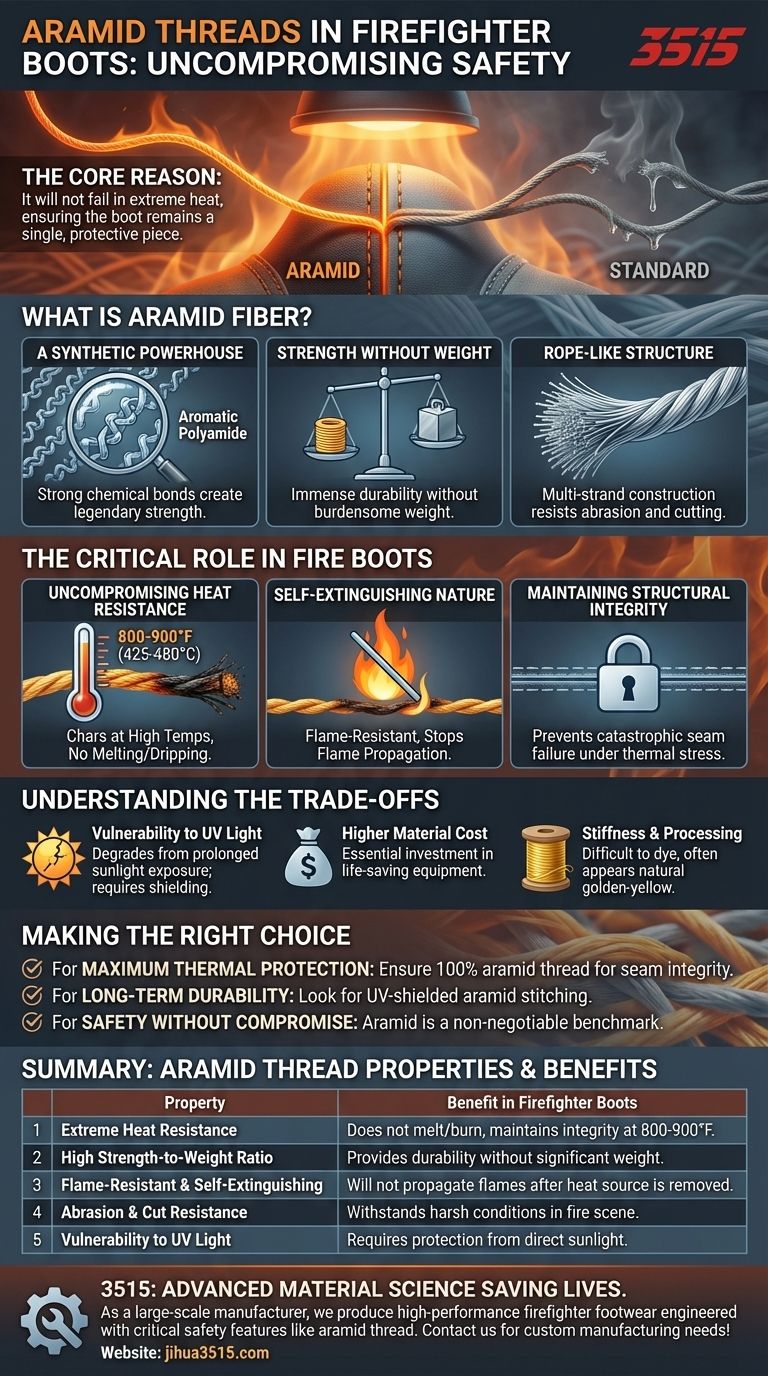

At its core, aramid thread is a class of high-performance synthetic fiber used in firefighter boots for one critical reason: it will not fail when exposed to extreme heat. Unlike standard threads that would melt or burn away, aramid maintains its strength, ensuring the boot remains a single, protective piece of equipment when it matters most.

The use of aramid thread is a non-negotiable safety feature. Its purpose is to maintain the boot's structural integrity under thermal attack, preventing catastrophic seam failure that would expose the firefighter to direct harm.

What Exactly is an Aramid Fiber?

To understand why aramid is essential, we must first look at its fundamental properties. It is not simply a "strong thread"; it is an engineered material designed for performance in extreme environments.

A Synthetic Powerhouse

The name "aramid" is short for aromatic polyamide. This refers to its specific molecular structure, where strong chemical bonds create long, rigid polymer chains. This internal structure is the source of the fiber's legendary strength.

Strength Without Weight

Aramid fibers exhibit an exceptionally high strength-to-weight ratio. On an equal weight basis, some aramid fibers are more than five times stronger than steel, providing immense durability without adding burdensome weight to the boot.

A Rope-like Structure

As noted, these fibers are composed of thousands of microfilaments. This multi-strand construction, much like a steel cable, provides not only strength but also resistance to abrasion and cutting, which is common in a fire scene environment.

The Critical Role of Thread in Firefighter Boots

A boot is only as strong as its weakest point, which is often the stitching that holds it together. Using aramid thread transforms this potential vulnerability into a source of resilience.

Uncompromising Heat Resistance

The defining characteristic of aramid is its thermal stability. It does not melt or drip when exposed to flames. Instead, it begins to char at extremely high temperatures (around 800-900°F or 425-480°C), buying critical time and maintaining its form.

Self-Extinguishing Nature

Aramid fibers are inherently flame-resistant. This means they will not continue to burn after the initial heat source is removed. This self-extinguishing property prevents the seams themselves from propagating a flame across the boot.

Maintaining Structural Integrity

This is the ultimate goal. If the thread fails, the protective layers of the boot come apart. By using aramid, engineers ensure that the seams will hold together even when the surrounding materials are under intense thermal stress.

Understanding the Trade-offs

While aramid is the superior choice for this application, no material is without its specific limitations. Understanding these trade-offs provides a complete picture of the material.

Vulnerability to UV Light

The most significant weakness of aramid fibers is their degradation from prolonged exposure to ultraviolet (UV) light. This is why the thread is often protected or used in areas not constantly exposed to direct sunlight.

Higher Material Cost

As a high-performance, specialized material, aramid is significantly more expensive than conventional threads like nylon or polyester. However, in the context of life-saving equipment, this cost is considered an essential investment in safety.

Stiffness and Processing

Aramid can be stiffer than other fibers and is notoriously difficult to dye, which is why it often appears in its natural golden-yellow color. These are manufacturing challenges rather than performance drawbacks in a finished boot.

Making the Right Choice for Your Goal

When evaluating safety equipment, understanding the role of materials like aramid allows for a more informed assessment of its true protective capabilities.

- If your primary focus is maximum thermal protection: You must ensure that all structural stitching on a boot uses 100% aramid thread, as this is the only way to guarantee seam integrity in a flashover event.

- If your primary focus is long-term durability: Look for designs where the aramid stitching is shielded from constant UV exposure, such as being recessed in channels, to maximize the service life of the equipment.

- If your primary focus is safety without compromise: Recognize that the use of aramid thread is a non-negotiable benchmark for any structural firefighting boot, and its absence indicates a product unsuitable for the role.

Ultimately, the choice to use aramid thread in firefighter boots is a clear example of how advanced material science directly contributes to saving lives.

Summary Table:

| Aramid Thread Property | Benefit in Firefighter Boots |

|---|---|

| Extreme Heat Resistance | Does not melt or burn, maintains integrity at 800-900°F (425-480°C) |

| High Strength-to-Weight Ratio | Provides durability without adding significant weight |

| Flame-Resistant & Self-Extinguishing | Will not propagate flames after heat source is removed |

| Abrasion & Cut Resistance | Withstands harsh conditions in a fire scene environment |

| Vulnerability to UV Light | Requires protection from direct sunlight for long-term durability |

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including firefighter footwear engineered with critical safety features like aramid thread stitching. Ensure your team is equipped with gear that meets the highest safety standards — contact us today to discuss your custom manufacturing needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- How do specialized safety shoes protect against battery maintenance injuries? Prevent Impact and Chemical Burns

- How do industrial safety shoes and tactical boots prevent Knee Osteoarthritis? Enhance Joint Health with Precision Gear

- What are the primary ergonomic design objectives of industrial-grade Safety Shoes? Enhancing Worker Comfort and Health

- How does professional foot protection prevent fractures? Advanced Shielding and Impact Dissipation

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What is the ANSI standard for safety footwear? It's Now ASTM F2413 for OSHA Compliance

- How does the upper material of a safety boot affect safety and comfort? Find the Right Shield for Your Feet

- What role do high-precision foot scanning devices play in industrial safety footwear? Digital Precision for Safety