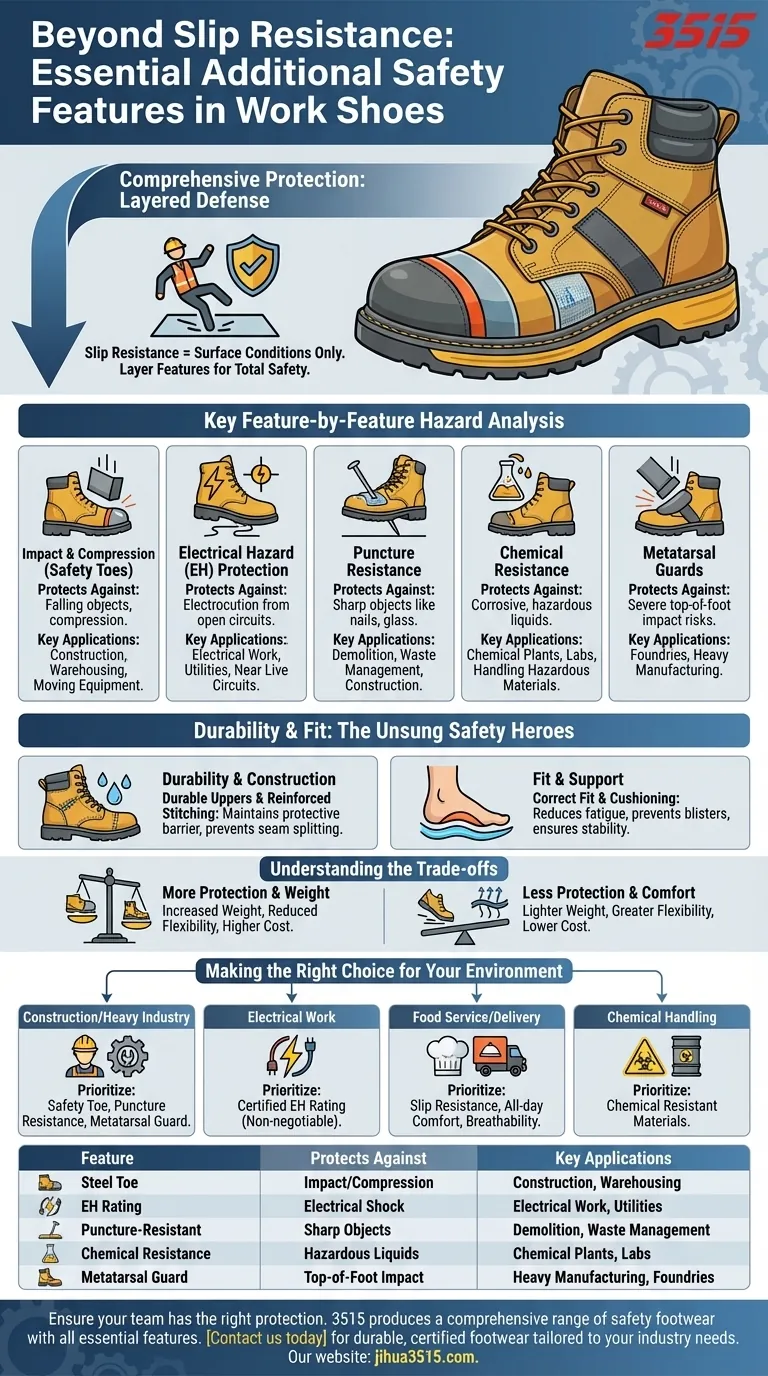

To ensure comprehensive protection, slip-resistant work shoes often require additional safety features tailored to specific environmental hazards. The most common requirements include steel toe caps for impact protection, electrical hazard (EH) ratings for work near live circuits, puncture-resistant soles for environments with sharp objects, chemical-resistant materials for handling hazardous liquids, and metatarsal guards for shielding the top of the foot.

The core principle is that slip resistance addresses only one type of hazard—surface conditions. True workplace safety is achieved by layering on specific protective features that directly counter the other unique risks of your job.

Beyond Grip: A Feature-by-Feature Hazard Analysis

Choosing the right work shoe begins with a clear assessment of your daily tasks and potential dangers. Each safety feature is engineered to solve a specific problem.

Impact and Compression Protection (Safety Toes)

The most recognized safety feature is the reinforced toe cap. It is essential for any role involving heavy objects, moving equipment, or compression risks. These are often referred to as steel toe boots, though composite materials are also common.

Electrical Hazard (EH) Protection

For electricians or anyone working near open circuits, Electrical Hazard (EH) rated footwear is non-negotiable. These shoes are constructed with non-conductive materials to provide a secondary source of protection against electrocution from accidental contact with live electrical conductors.

Puncture Resistance

Jobs in construction, demolition, or waste management often expose workers to sharp objects on the ground like nails, glass, or metal shards. Puncture-resistant shoes have a protective plate built into the midsole to prevent these items from piercing the sole and injuring the foot.

Chemical Resistance

When working with corrosive or hazardous liquids, the shoe's upper material becomes critical. Chemically resistant footwear is made from specialized materials that resist degradation and prevent dangerous substances from reaching the skin.

Metatarsal Guards

For maximum protection in environments with severe impact risks, such as foundries or heavy manufacturing, metatarsal guards are essential. These external shields cover the top of the foot (the metatarsal bones), an area left exposed by standard safety toe caps.

Durability and Construction: The Unsung Safety Features

A shoe's ability to protect you is directly tied to its structural integrity. Features that enhance durability are, by extension, critical safety features.

The Role of Upper Materials

The choice of material for the shoe's upper section dictates its performance. Waterproof synthetics are ideal for wet conditions, while mesh and breathable fabrics are better for hot environments to prevent discomfort and sweating, which can lead to slipping inside the shoe.

The Importance of Reinforced Stitching

Durable, reinforced stitching prevents seams from splitting under stress. This ensures the shoe remains a solid barrier between your foot and the work environment, maintaining its protective qualities over time.

Understanding the Trade-offs

Adding protective features almost always involves a compromise. Understanding these trade-offs is key to selecting a shoe you can comfortably and safely wear all day.

The Weight Factor

More protection, especially from steel toes and metatarsal guards, inevitably adds weight. This can increase fatigue over a long shift, which can itself become a safety risk by reducing alertness.

Flexibility and Breathability

Puncture-resistant plates can make a shoe feel stiffer and less flexible. Likewise, waterproof or chemically resistant materials often sacrifice breathability, which can lead to discomfort in warm conditions.

The Cost Implication

Highly specialized shoes with multiple certifications and advanced materials will have a higher price point. It's an investment in safety that should be weighed against the specific hazards you face.

The Foundation of All-Day Safety: Fit and Support

An ill-fitting or unsupportive shoe is a safety hazard, regardless of its features. Discomfort is a distraction, and poor support can lead to fatigue and long-term injury.

Ensuring the Correct Fit

Always try on shoes before buying them, wearing the same type of socks you use for work. Ensure there is enough room in the toe box and that the width is snug but not constricting. A proper fit prevents chafing and blisters.

Cushioning and Arch Support

For anyone who spends hours on their feet, proper cushioning and arch support are paramount. They reduce strain on your feet, legs, and back, preventing the fatigue that can lead to missteps and accidents.

Making the Right Choice for Your Environment

Your specific job function is the ultimate guide to selecting the right combination of features.

- If your primary focus is construction or heavy industry: Prioritize impact protection (safety toe), puncture resistance, and potentially metatarsal guards.

- If your primary focus is electrical work: A certified Electrical Hazard (EH) rating is your non-negotiable starting point.

- If your primary focus is food service or delivery: Slip resistance is king, but prioritize all-day comfort with excellent cushioning, arch support, and breathability.

- If your primary focus is handling chemicals: You must select a shoe made from materials specifically rated for chemical resistance.

Ultimately, the safest work shoe is one that accurately matches its protective features to the real-world risks of your job.

Summary Table:

| Safety Feature | Protects Against | Key Applications |

|---|---|---|

| Steel Toe Cap | Impact & Compression | Construction, Warehousing |

| EH Rating | Electrical Shock | Electrical Work, Utilities |

| Puncture-Resistant Sole | Sharp Objects | Demolition, Waste Management |

| Chemical Resistance | Hazardous Liquids | Chemical Plants, Labs |

| Metatarsal Guard | Top-of-Foot Impacts | Heavy Manufacturing, Foundries |

Ensure your team has the right protection for every hazard. As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear with all essential features—from slip-resistant soles to steel toes and EH ratings—for distributors, brand owners, and bulk clients. Our production capabilities cover all types of safety shoes and boots tailored to your specific industry needs. Contact us today for durable, certified footwear that meets your exact safety requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now