Beyond their classic style, many Western work boots incorporate specialized safety features designed for hazardous environments. The most notable additional protections are integrated heat-resistant outsoles for high-temperature surfaces and electrical hazard (EH) ratings to protect against accidental contact with live electrical circuits.

The key is to understand that a "Western work boot" is more than just an aesthetic. It's a category of purpose-built footwear where traditional design meets modern, certified safety technologies that you must match to your specific job's risks.

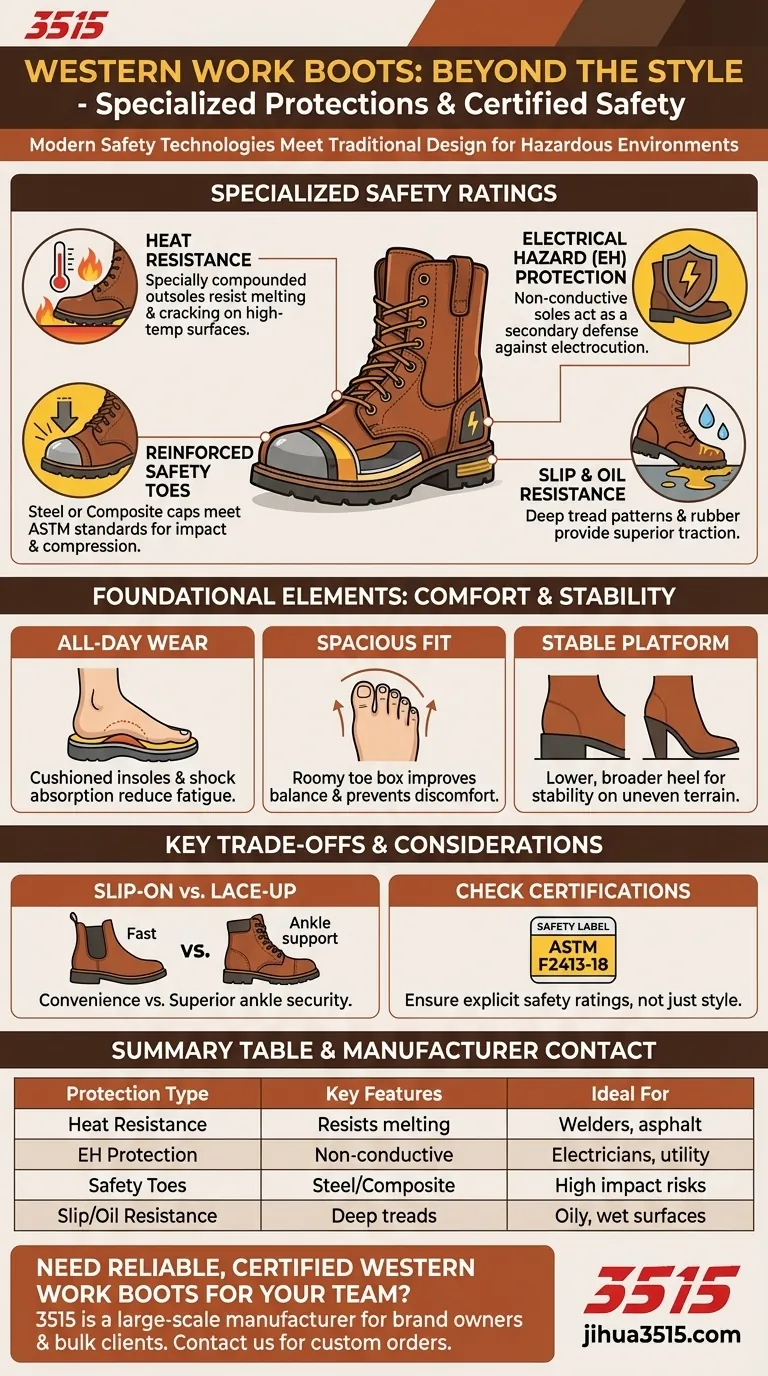

Beyond the Basics: Specialized Safety Ratings

While all quality work boots provide a baseline of durability, certain Western styles are engineered with specific protections for high-risk professions. You must look for these explicit ratings, not just assume the style provides the feature.

Heat Resistance

For welders, asphalt workers, or anyone working on high-temperature surfaces, some Western work boots feature specially compounded outsoles. These are designed to resist melting, cracking, and degradation when exposed to extreme heat from below.

Electrical Hazard (EH) Protection

Boots with an EH rating are a critical line of defense for electricians and utility workers. They are constructed with non-conductive, shock-resistant soles and heels, providing a secondary source of protection from electrocution.

Reinforced Safety Toes

Just like traditional work boots, Western models are available with reinforced toe caps that meet industry safety standards. These can be steel toes for maximum impact resistance or composite toes, which are lighter, don't conduct heat or electricity, and won't set off metal detectors.

Slip and Oil Resistance

The foundation of on-the-job safety is stable footing. Many Western work boots feature thick rubber outsoles with tread patterns specifically designed to provide superior traction and resist degradation from oils and other chemicals.

The Foundational Elements of a Western Work Boot

Beyond specialized ratings, the inherent design of a Western work boot contributes to both safety and comfort, which are intrinsically linked. A comfortable worker is a more focused and less fatigued worker.

Designed for All-Day Wear

Western work boots are built for long hours on your feet. They often feature cushioned insoles, molded footbeds for shock absorption, and built-in arch support. These elements work together to reduce fatigue and prevent chronic pain.

A More Spacious Fit

A key characteristic is the roomy toe box. This allows your toes to spread naturally, improving balance and preventing the discomfort and blistering that can come from more restrictive footwear.

Stability and Structure

Unlike a traditional cowboy boot with a high, angled heel for stirrups, a Western work boot has a lower, broader heel block. This creates a much more stable platform for walking and standing on uneven job site surfaces.

Understanding the Trade-offs

Choosing a Western work boot involves balancing its unique advantages with potential limitations.

Slip-On vs. Lace-Up

The primary trade-off is convenience for ankle security. The slip-on design of a Western boot is fast and easy, but it inherently offers less ankle stabilization against rolling than a traditional, tightly-laced work boot.

Style and Professionalism

While rugged and iconic, the distinct look of a Western boot may not be appropriate for every work environment or client-facing role.

Not All Styles Are Created Equal

It is critical to remember that a "Western-style" boot is not automatically a "work boot." True work boots will be clearly marked with their safety certifications (e.g., ASTM F2413-18 for safety toes and EH ratings). Decorative stitching does not equal protection.

Making the Right Choice for Your Job

Your choice should be dictated entirely by the certified protection you need, not just the style you prefer.

- If you work in high-heat or electrical environments: Seek out boots explicitly advertised with heat-resistant outsoles or an official EH rating.

- If your primary risk is falling objects or compression: Ensure the boot has an ASTM-certified steel or composite safety toe.

- If you spend all day on your feet on hard surfaces: Prioritize models that emphasize their cushioned insoles, arch support, and roomy fit to minimize fatigue.

- If your job involves climbing or walking on highly unstable terrain: A traditional lace-up boot may offer superior ankle support and be a safer choice.

Ultimately, selecting the right Western work boot means matching certified safety features to the specific demands of your work.

Summary Table:

| Protection Type | Key Features | Ideal For |

|---|---|---|

| Heat Resistance | Specially compounded outsoles resist melting/cracking | Welders, asphalt workers |

| Electrical Hazard (EH) | Non-conductive soles for shock protection | Electricians, utility workers |

| Reinforced Safety Toes | Steel/composite toes meeting ASTM standards | High-impact/compression risks |

| Slip & Oil Resistance | Deep tread patterns, chemical-resistant rubber | Oily, wet, or unstable surfaces |

Need Reliable, Certified Western Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified work boots, including Western styles with heat-resistant, EH-rated, and slip-resistant features—ensuring your workforce stays protected and productive.

Contact us today to discuss your custom or bulk order requirements!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?