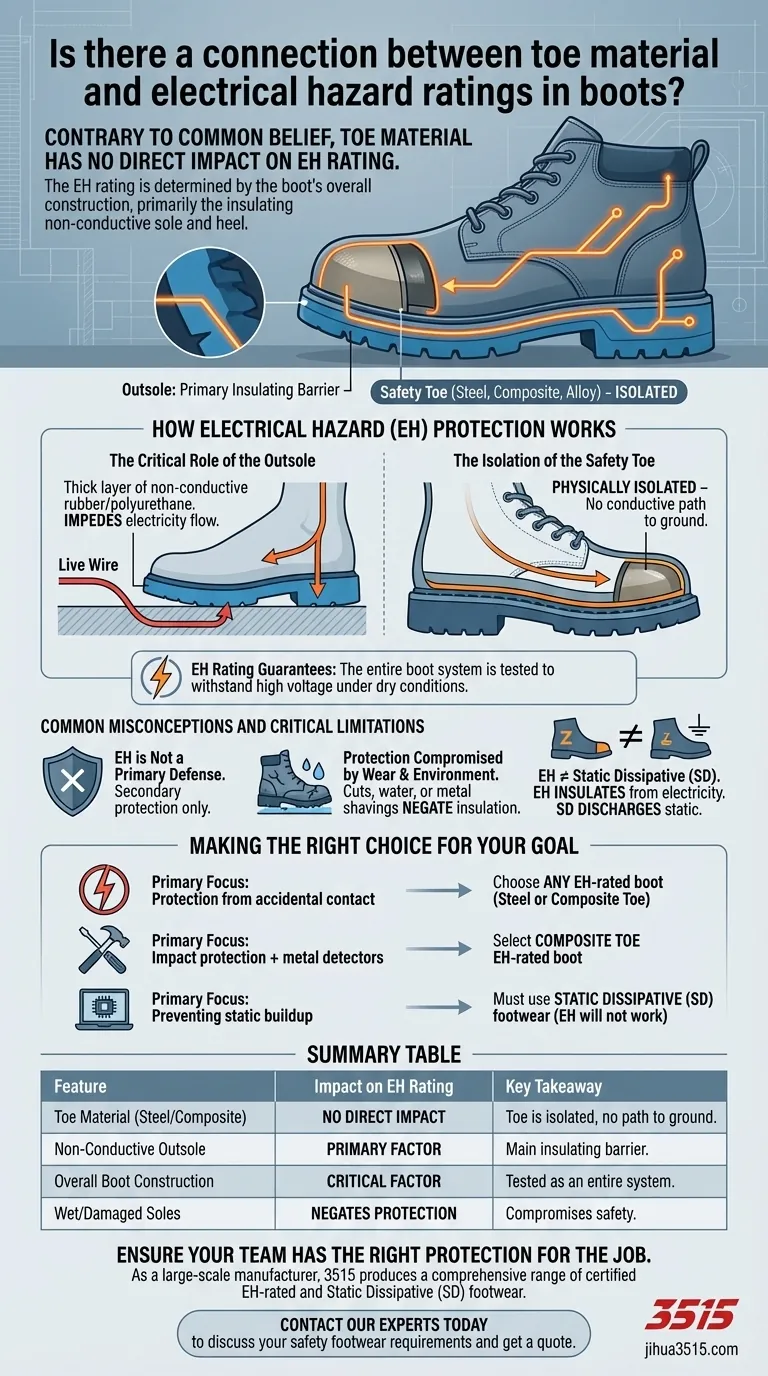

Contrary to common belief, the material of the safety toe in a work boot—whether it is steel, composite, or alloy—has no direct impact on its Electrical Hazard (EH) rating. An EH rating is determined by the boot's overall construction and its ability to provide insulation from the ground, a function performed primarily by the non-conductive sole and heel.

The core principle of EH protection lies in insulating the wearer from the ground. Because the safety toe is encased within the boot and sits on top of the insulating outsole, it never forms a conductive path that would compromise the boot's safety rating.

How Electrical Hazard (EH) Protection Works

To understand why toe material is irrelevant, you must first understand the purpose of an EH-rated boot. It is designed to be a secondary source of protection against accidental contact with live electrical circuits.

The Critical Role of the Outsole

The outsole is the true hero of an EH-rated boot. This thick layer of non-conductive rubber or polyurethane acts as the primary barrier between your foot and the ground.

This barrier is designed and tested to impede the flow of electricity, protecting you from becoming part of a circuit if you step on a live wire.

The Isolation of the Safety Toe

The safety toe cap is physically isolated within the boot's structure. It sits on top of the main insulating outsole and is separated from your foot by the insole and other interior materials.

Because it doesn't touch the ground or create a path through your body, its material composition—conductive or not—is functionally irrelevant to the EH rating.

What an EH Rating Guarantees

A boot certified with an EH rating has been tested to withstand the application of a very high voltage for at least one minute under dry conditions.

This proves the entire boot construction, from the sole to the cements and upper materials like leather, works as a system to resist electrical current.

Common Misconceptions and Critical Limitations

Trusting your safety to your equipment requires understanding not just what it does, but also what it doesn't do. EH-rated footwear has specific limitations that are critical to recognize.

EH is Not a Primary Defense

EH boots are a secondary source of protection. They are not intended for environments where you are in constant or direct contact with live circuits, such as climbing utility poles.

Protection is Compromised by Wear and Environment

The insulating properties of your boots can be negated by several factors. Excessive wear, cuts in the sole, or exposure to water can create a path for electricity to travel.

Furthermore, if the sole becomes embedded with metal shavings or other conductive materials, its protective capabilities will be significantly reduced.

Confusing EH with Other Electrical Ratings

Do not confuse EH with Static Dissipative (SD) footwear. EH boots insulate you from electricity, while SD boots are designed to safely discharge small amounts of static electricity to the ground to protect sensitive electronic equipment. Using one where the other is required can be dangerous.

Making the Right Choice for Your Goal

Selecting the correct footwear is about matching the boot's certified properties to your specific work environment and safety requirements.

- If your primary focus is protection from accidental contact with live circuits: Choose any boot with a certified EH rating; the toe material (steel or composite) offers identical electrical protection.

- If your primary focus is impact protection and you also pass through metal detectors: Select a composite toe EH-rated boot for convenience, knowing its safety is not compromised.

- If your primary focus is preventing static buildup around sensitive electronics: You must use Static Dissipative (SD) footwear, as EH boots will not provide this function.

Ultimately, understanding how your safety gear functions is the first step toward ensuring it can protect you effectively.

Summary Table:

| Feature | Impact on EH Rating | Key Takeaway |

|---|---|---|

| Toe Material (Steel/Composite) | No Direct Impact | The toe is isolated and does not create a path to the ground. |

| Non-Conductive Outsole | Primary Factor | The rubber/polyurethane sole is the main insulating barrier. |

| Overall Boot Construction | Critical Factor | The entire boot is tested as a system for electrical resistance. |

| Wet/Damaged Soles | Negates Protection | Cuts, moisture, or embedded metal can compromise safety. |

Ensure your team has the right protection for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of certified EH-rated and Static Dissipative (SD) footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes, ensuring you get the exact specification and certification your workforce needs.

Contact our experts today to discuss your safety footwear requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries