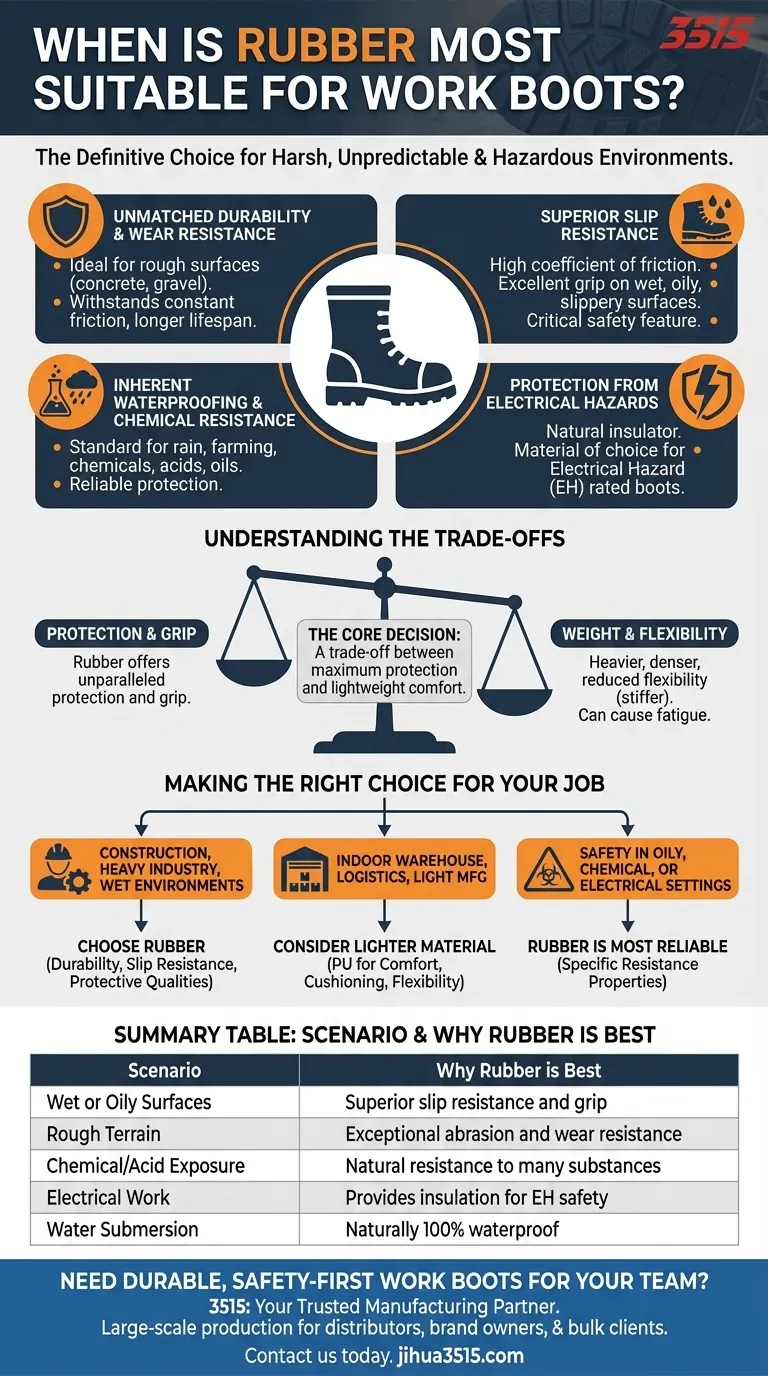

In the simplest terms, rubber is the most suitable material for work boots in harsh, unpredictable, and hazardous environments. Its inherent properties make it the definitive choice for jobs where maximum protection, durability, and slip resistance are non-negotiable priorities over lightweight comfort.

The core decision comes down to a simple trade-off: Rubber offers unparalleled protection and grip in hazardous conditions, but this robustness comes at the cost of increased weight and reduced flexibility compared to lighter synthetic materials.

Why Rubber Excels in Demanding Environments

The physical properties of rubber make it uniquely suited for the most challenging job sites. It is not simply one feature, but the combination of its characteristics that provides a superior safety profile.

Unmatched Durability and Wear Resistance

Rubber has exceptional abrasion resistance. This makes it ideal for work on rough surfaces like concrete, gravel, or scaffolding.

Unlike softer materials, it withstands constant friction and contact with sharp objects, leading to a significantly longer lifespan for the boot's outsole.

Superior Slip Resistance

Rubber naturally has a high coefficient of friction. This provides an excellent grip on wet, oily, or otherwise slippery surfaces.

For industries where spills are common or outdoor work is performed in all weather, this characteristic is a critical safety feature that directly prevents falls.

Inherent Waterproofing and Chemical Resistance

Solid rubber is naturally waterproof, which is why it's the standard for rain boots and footwear used in farming, fishing, or pressure washing.

Furthermore, it offers reliable protection against many common industrial chemicals, acids, and oils that can degrade other sole materials.

Protection from Electrical Hazards

Rubber is a natural insulator, meaning it does not conduct electricity well.

This property makes it the material of choice for Electrical Hazard (EH) rated boots, which are designed to protect workers from accidental contact with live electrical circuits.

Understanding the Trade-offs

No material is perfect for every application. The very properties that make rubber exceptionally protective also create its primary disadvantages.

The Issue of Weight

Rubber is denser and heavier than synthetic alternatives like Polyurethane (PU).

Over a long workday with constant walking, this added weight can contribute to foot and leg fatigue.

Reduced Flexibility

Rubber soles tend to be stiffer than their PU counterparts.

This can make them less comfortable for roles that require constant crouching, kneeling, or agile movement. For daily wear or light outdoor activities, this rigidity can be a noticeable drawback.

Making the Right Choice for Your Job

Selecting the right boot sole is about matching the material's strengths to the specific demands and hazards of your work environment.

- If your primary focus is construction, heavy industry, or wet environments: Choose rubber for its unmatched durability, slip resistance, and protective qualities.

- If your primary focus is indoor warehouse work, logistics, or light manufacturing: Consider a lighter material like PU for better all-day comfort, cushioning, and flexibility.

- If your primary focus is safety in oily, chemical, or electrical settings: A rubber sole is the most reliable choice for its specific resistance properties.

Ultimately, choosing the right material for your work boot's sole is a critical decision that directly impacts your safety and comfort on the job.

Summary Table:

| Scenario | Why Rubber is Best |

|---|---|

| Wet or Oily Surfaces | Superior slip resistance and grip |

| Rough Terrain (e.g., concrete, gravel) | Exceptional abrasion and wear resistance |

| Chemical or Acid Exposure | Natural resistance to many industrial substances |

| Electrical Work | Provides insulation for Electrical Hazard (EH) safety |

| Water Submersion/Heavy Rain | Naturally 100% waterproof |

Need Durable, Safety-First Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance rubber work boots for distributors, brand owners, and bulk clients. Our boots are engineered for the toughest conditions, offering the unmatched protection, durability, and slip resistance detailed in this article.

Let 3515 be your trusted manufacturing partner. We can help you equip your workforce with the right footwear to enhance safety and productivity.

Contact us today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Durable Moc Toe Wedge Sole Work Boots for Wholesale and Private Label

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- Why are safety boots and chemical-resistant trousers vital for paddy fields? Protect Your Workers Today

- What is the benefit of using a leather protecting cream on work boots? Prevent Cracking & Extend Boot Life

- Which type of boot is more breathable: waterproof or water-resistant? Find Your Perfect Fit.

- What are the properties of rubber as an upper material for work boots? A Guide to Waterproof Durability vs. Comfort

- What is metatarsal guard protection in mining boots? Essential Safety for Heavy Industry

- What should be considered regarding the sole design and material of work boots? Maximize Safety & Comfort

- Are zippers common in cowboy boots? The Truth About Authentic vs. Modern Western Boots

- What materials are used in Western work boots? A Guide to Durability, Safety & Comfort