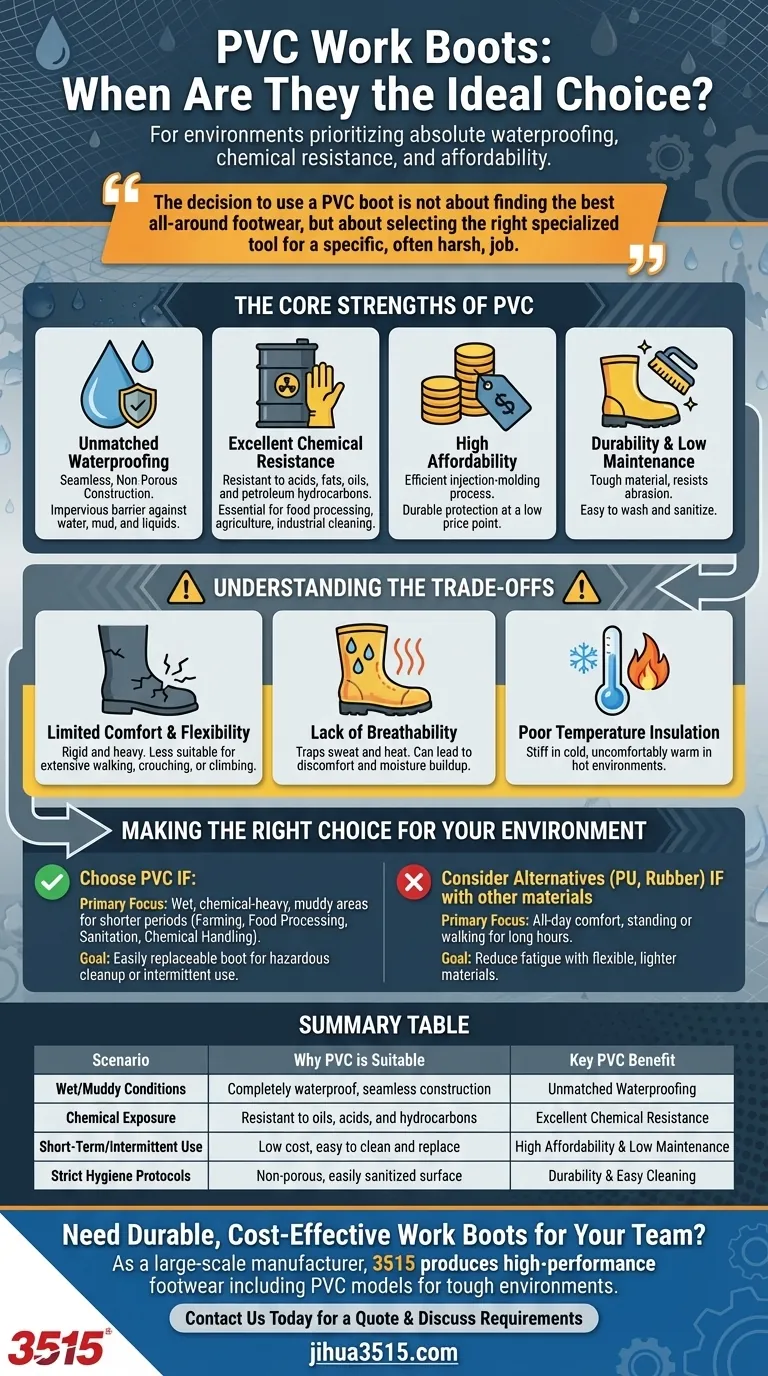

In short, PVC work boots are most suitable for environments where absolute waterproofing, chemical resistance, and affordability are the highest priorities. They are the ideal choice for short-term or intermittent use in wet, muddy, or contaminated conditions where long-term comfort and breathability are not primary concerns.

The decision to use a PVC boot is not about finding the best all-around footwear, but about selecting the right specialized tool for a specific, often harsh, job. It excels where other materials might fail or be prohibitively expensive.

The Core Strengths of PVC

Polyvinyl Chloride (PVC) is a synthetic plastic polymer. Its inherent properties, combined with an efficient injection-molding manufacturing process, give boots made from it a distinct set of advantages for particular tasks.

Unmatched Waterproofing

Because PVC is a non-porous plastic, boots are molded in a single, seamless form. This construction method eliminates stitches and joints that could otherwise become points of failure, creating a completely impervious barrier against water, mud, and other liquids.

Excellent Chemical Resistance

PVC is naturally resistant to a wide range of common chemicals, including many acids, fats, oils, and petroleum hydrocarbons. This makes it an essential material for workers in food processing, agriculture, and industrial cleaning where such exposures are common.

High Affordability

The injection-molding process used to create PVC boots is highly efficient and uses relatively inexpensive raw materials. This results in a durable, protective boot at a very low price point, making it a practical choice for large crews or for jobs that quickly soil or destroy footwear.

Durability and Low Maintenance

PVC is a tough material that resists abrasion and scuffs well. It requires no special care and can be easily washed and sanitized, which is a critical feature for industries with strict hygiene protocols.

Understanding the Trade-offs

No material is perfect for every application. The same properties that make PVC excellent for specific jobs also create its primary limitations. Understanding these trade-offs is key to making an informed choice.

Limited Comfort and Flexibility

PVC is a relatively rigid and heavy material compared to alternatives like polyurethane (PU) or rubber. This stiffness makes it less suitable for tasks that require extensive walking, crouching, or climbing, and it can lead to fatigue over a long workday.

Lack of Breathability

The same non-porous quality that makes PVC completely waterproof also means it is not breathable. It traps sweat and heat, which can lead to discomfort, moisture buildup, and potential skin issues during extended wear.

Poor Temperature Insulation

PVC offers very little insulation. It tends to become stiff and cold in low temperatures and can become uncomfortably warm in hot environments, transferring the ambient temperature directly to the wearer's foot.

Making the Right Choice for Your Environment

Your specific work environment and the duration of wear should be the deciding factors when choosing a work boot.

- If your primary focus is working in wet, chemical-heavy, or muddy areas for shorter periods: PVC is the ideal, cost-effective choice for tasks in farming, food processing, sanitation, and chemical handling.

- If your primary focus is all-day comfort while standing or walking for long hours: You should look for boots made from more flexible and lighter materials like PU or rubber, as PVC's weight and rigidity will likely cause fatigue.

- If your primary focus is finding an easily replaceable boot for hazardous material cleanup or intermittent use: PVC's low cost and high chemical resistance make it a perfect solution.

Choosing the right boot means matching the material's properties to the demands of your job.

Summary Table:

| Scenario | Why PVC is Suitable | Key PVC Benefit |

|---|---|---|

| Wet/Muddy Conditions | Completely waterproof, seamless construction | Unmatched Waterproofing |

| Chemical Exposure | Resistant to oils, acids, and hydrocarbons | Excellent Chemical Resistance |

| Short-Term/Intermittent Use | Low cost, easy to clean and replace | High Affordability & Low Maintenance |

| Strict Hygiene Protocols | Non-porous, easily sanitized surface | Durability and Easy Cleaning |

Need Durable, Cost-Effective Work Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized shoes and boots, including PVC models designed for the toughest environments.

We can provide your team with the right protective footwear that combines durability, chemical resistance, and affordability.

Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the characteristics of rubber work boots? Unmatched Waterproofing for Wet & Chemical Environments

- What are some ASTM standards for work boots? A Guide to Certified Footwear Safety

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What comfort features are incorporated into Western work boots? All-Day Support for Demanding Work

- What options are available for restoring worn-out work boots? Expert Strategies for Longevity

- What protective functions do industrial-grade safety boots provide in construction and mining? Maximize Worker Safety

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- Who are pull-on work boots most suitable for? Ideal for Farmers, Ranchers & Construction Pros