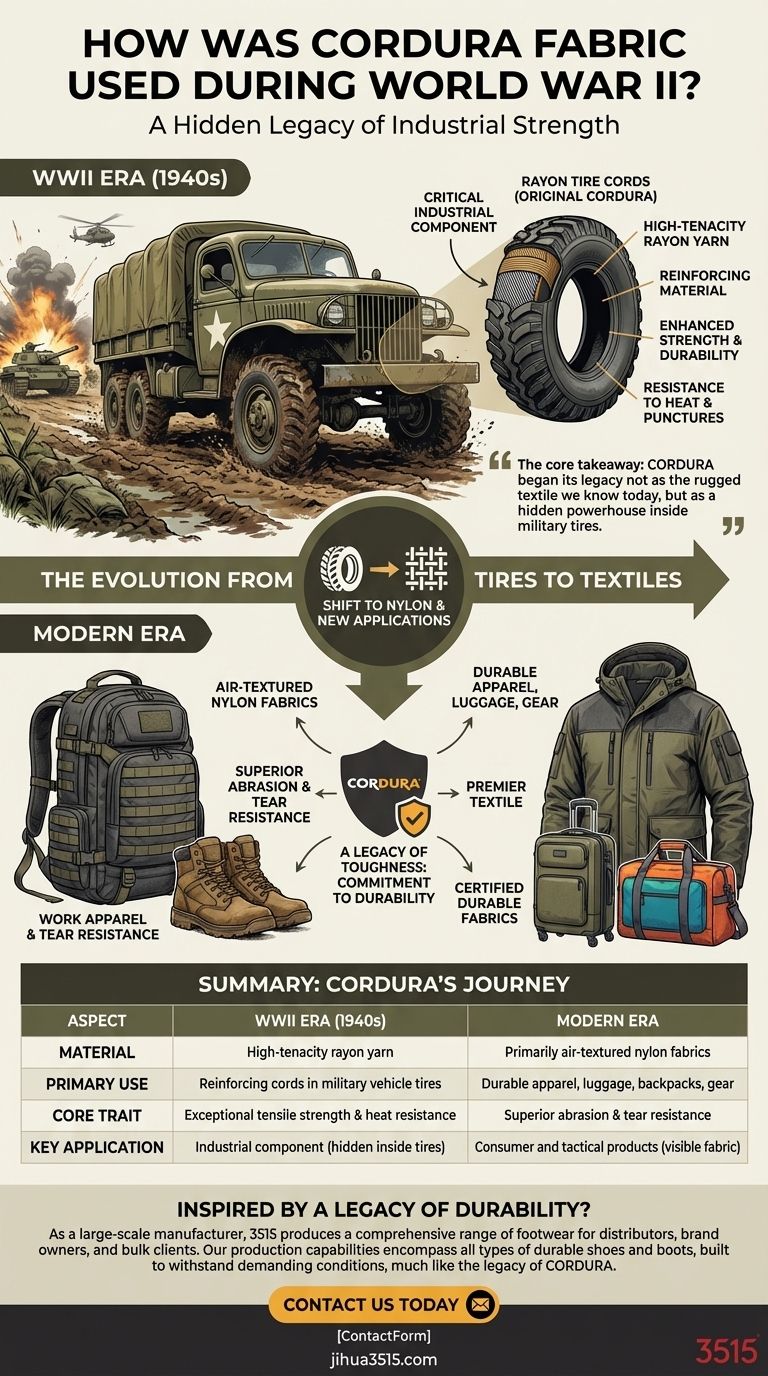

During World War II, the original CORDURA was not a fabric for bags or jackets but a critical industrial component developed by DuPont. The military used this high-tenacity rayon yarn as a reinforcing material in the manufacturing of tires for military vehicles, enhancing their strength and durability for harsh wartime conditions.

The core takeaway is that CORDURA began its legacy not as the rugged textile we know today, but as a hidden powerhouse inside military tires, where its foundational trait—exceptional durability—was first proven.

The Original CORDURA: A Tire's Inner Strength

The story of CORDURA starts with an industrial need, not a consumer one. Its first application was a solution to a critical engineering problem faced by the military during a global conflict.

A DuPont Innovation for Durability

In the era of chemical innovation, DuPont engineered CORDURA as a high-strength rayon yarn. Its key characteristic was a molecular structure that provided immense tensile strength and resistance to heat.

This made it the perfect material to create the inner "cords" or plies of a tire. These cords form the tire's skeleton, providing the structural integrity needed to handle heavy loads and rough terrain.

Solving a Wartime Challenge

Military vehicles in World War II operated in extreme environments, from muddy fields to desert landscapes. Standard tires of the era were a common point of failure, disrupting supply lines and disabling vehicles.

By incorporating CORDURA rayon cords, tires became significantly more robust. They were more resistant to punctures, heat degradation, and the general stress of military use, directly improving the reliability of the Allied vehicle fleet.

The Evolution from Tires to Textiles

The CORDURA brand we recognize today is fundamentally different in material composition but identical in principle. The success of the name in an industrial setting paved the way for its reinvention as a premier textile.

The Shift to Nylon

While the WWII-era product was rayon, the CORDURA brand was later applied to a new type of air-textured nylon fabric. This new material retained the core concept of durability but translated it into a textile suitable for apparel and gear.

This modern CORDURA offered superior abrasion and tear resistance, making it ideal for applications where fabric faces constant wear.

From Industrial Component to Everyday Gear

The brand's reputation for toughness was reborn in consumer and military products. Its use expanded into luggage, backpacks, footwear, and performance apparel—items where longevity and resistance to damage are paramount.

The same principle that made tires more reliable now makes a backpack last for decades.

Understanding the CORDURA Identity

To grasp its history, it's crucial to distinguish between the original product and the modern brand. The name signifies a standard of performance, not one single material.

It's a Brand, Not a Single Fabric

CORDURA is a brand name for a family of certified durable fabrics. While most commonly associated with nylon, the brand encompasses various materials, including polyesters and blends.

A Legacy of Toughness

The common thread from the rayon tire cords of the 1940s to the advanced textiles of today is an unwavering commitment to durability. The application has changed, but the core value proposition has not.

How to Understand CORDURA's Legacy

Your perspective on CORDURA's history depends on what you want to understand about it.

- If your primary focus is historical accuracy: Remember that WWII CORDURA was a rayon yarn used exclusively to reinforce military tires, not a fabric used for clothing or bags at that time.

- If your primary focus is material science: The key insight is the brand's successful evolution from an industrial rayon to a family of high-performance textiles, primarily nylon, by transferring a core identity of extreme toughness.

This journey from a tire's hidden strength to the benchmark for rugged gear is a testament to the enduring value of durability.

Summary Table:

| Aspect | WWII Era (1940s) | Modern Era |

|---|---|---|

| Material | High-tenacity rayon yarn | Primarily air-textured nylon fabrics |

| Primary Use | Reinforcing cords in military vehicle tires | Durable apparel, luggage, backpacks, gear |

| Core Trait | Exceptional tensile strength & heat resistance | Superior abrasion & tear resistance |

| Key Application | Industrial component (hidden inside tires) | Consumer and tactical products (visible fabric) |

Inspired by a legacy of durability?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, built to withstand demanding conditions, much like the legacy of CORDURA.

Contact us today to discuss how we can provide robust, reliable footwear solutions for your business.

Visual Guide

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What role did combat boots play in the Vietnam War? Beyond Practicality to Personal Identity

- How have desert boot designs expanded beyond traditional colors? Modern Palettes & Smart Styling

- What types of toes are generally authorized for Army boots? Plain-Toed Boots are the Standard

- What boots does the army use? The Ultimate Guide to Tactical Footwear

- How does a four-legged conversion bracket attachment reduce injury rates? Advanced Blast Protection & Mitigation

- What recommendations did NIST make for improving Army boots? Enhance Performance with Data-Driven Standards

- What are the general specifications for Army boots? A Guide to AR 670-1 Compliant Footwear

- What testing and feedback process was used to refine the jungle boot design? A Year-Long Soldier-Driven Iteration